Guide mechanism for reducing folding of adhesive tape in box sealing process

A technology of guiding mechanism and tape paper, applied in the directions of packaging sealing/fastening, transportation packaging, packaging, etc., can solve problems such as shaking of cigarette boxes, achieve the effects of reducing shaking, reducing folding, and improving image and brand image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

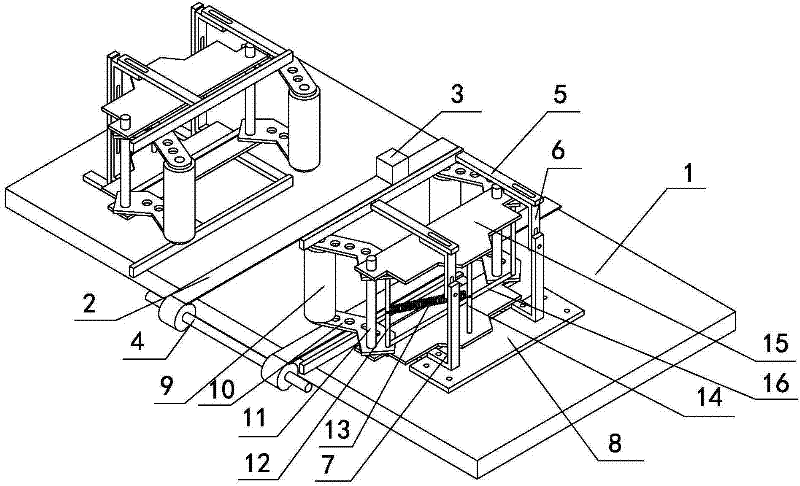

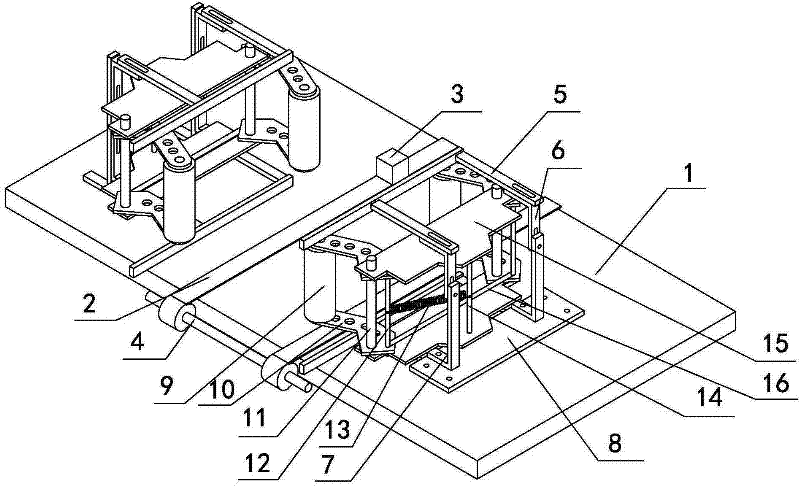

[0017] Please see attached figure 1 , those drawn in the accompanying drawings are the parts and components involved in the present invention, and other connecting components are not shown. In the present embodiment, it mainly includes a frame 1, a conveyor belt 2 and a guiding device. The frame 1 indicated in the present embodiment and the accompanying drawings is the frame part involved in the present invention, and the part not involved has no draw. The transmission belt 2 is arranged above the frame 1 to drive the smoke box forward. In this embodiment, a propulsion block 3 is fixedly installed on the transmission belt 2 to push the smoke box. The transmission belt 2 is driven forward by the transmission belt shaft 4 .

[0018] In the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com