Disposable water bag and processing method thereof

A processing method, a one-time technology, applied to chemical instruments and methods, bags, sacks, etc., can solve the problems of easy leakage, leaky water guide column and bag body, etc., to improve sealing performance, save recycling and flushing costs, Effect of improving impact strength and heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be further described through embodiments in conjunction with the drawings.

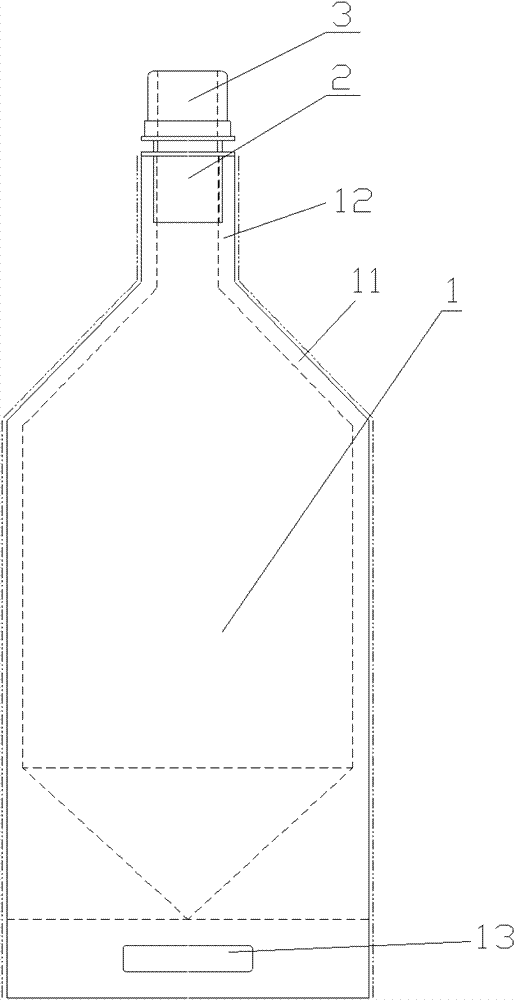

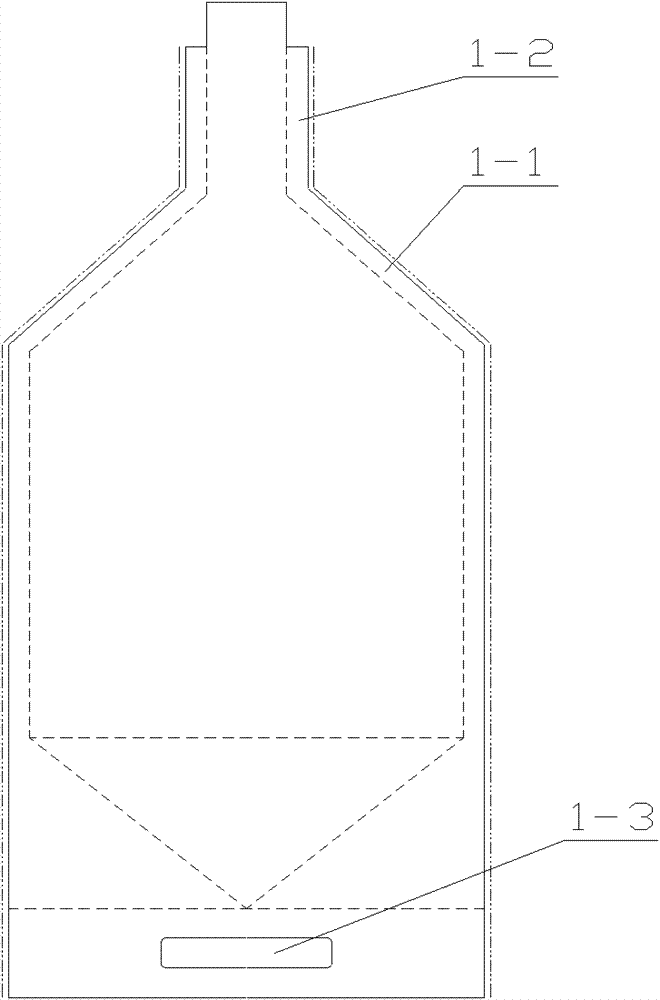

[0038] Such as Figure 1~3 As shown, the disposable water bag embodiment is provided with a bag body 1, a bag plug 2 and a plug cap 3.

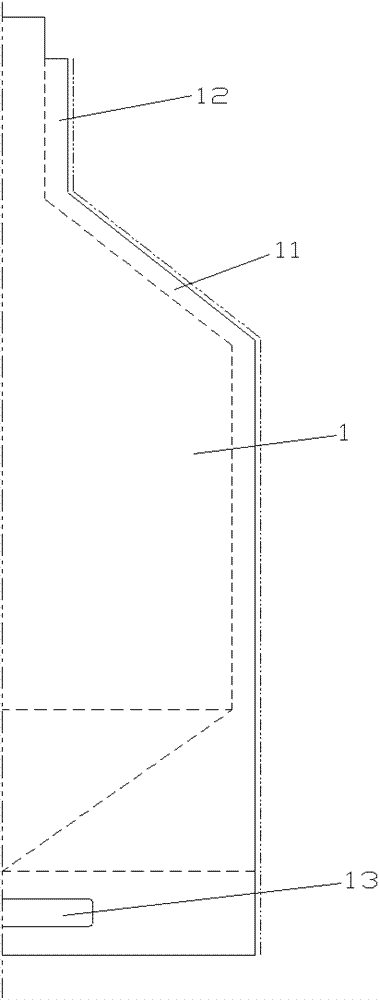

[0039] The bag body 1 is composed of an outer layer, a middle layer and an inner layer. The outer layer is a PET film with a thickness of 12 μm; the middle layer is a nylon film (PA) with a thickness of 15 μm; and the inner layer is a PE film with a thickness of 80 μm.

[0040] The edge of the bag body 1 is the heat-sealed adhesive edge, and the right angle of the bag body 1 is 45° heat-sealed and bonded chamfer 1-1; the upper part of the bag body 1 is the bottleneck 1-2 of the bag mouth, and the bottom of the bag body 1 (Outside the adhesive side) is provided with water bag hanging holes 1-3; the bag body 1 is folded into a 4-petal symmetrical structure by a bag making machine. In this embodiment, the edge bonding width of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com