Parallelogram type connection table

A parallelogram, connecting table technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, difficulty in adjusting the width of the feeding board, low transportation efficiency, etc., and achieves low manufacturing cost, low working noise, The effect of fast board transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

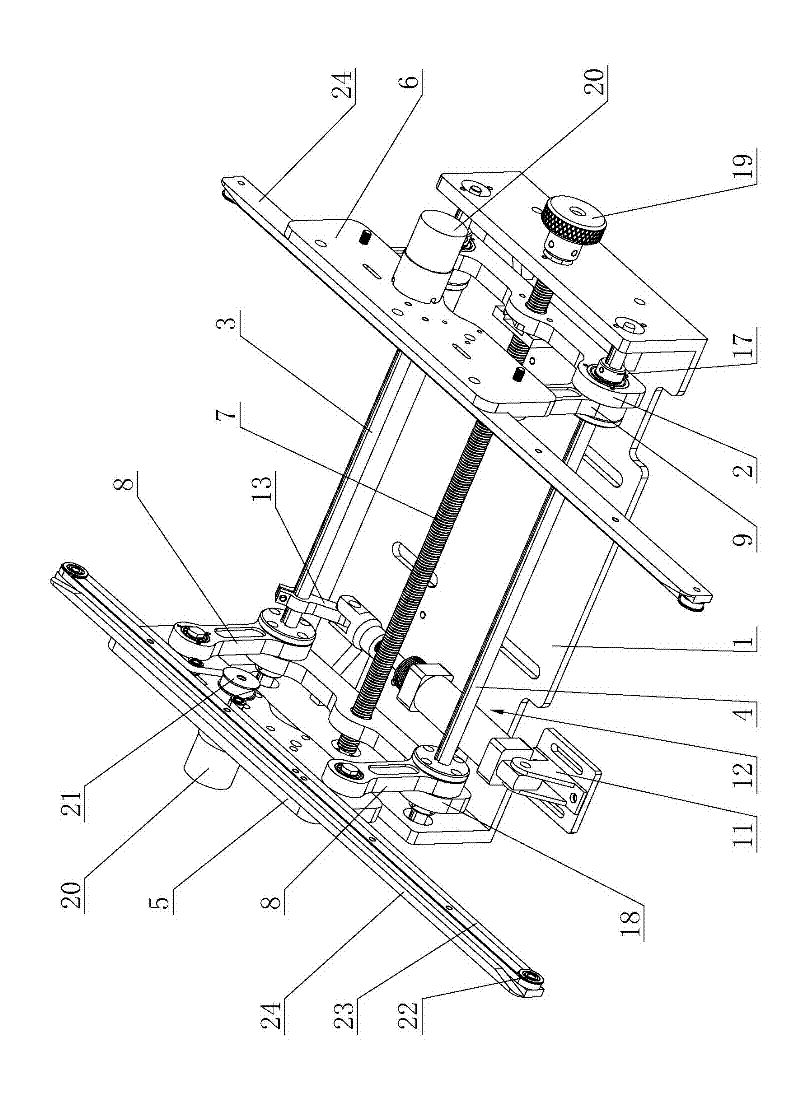

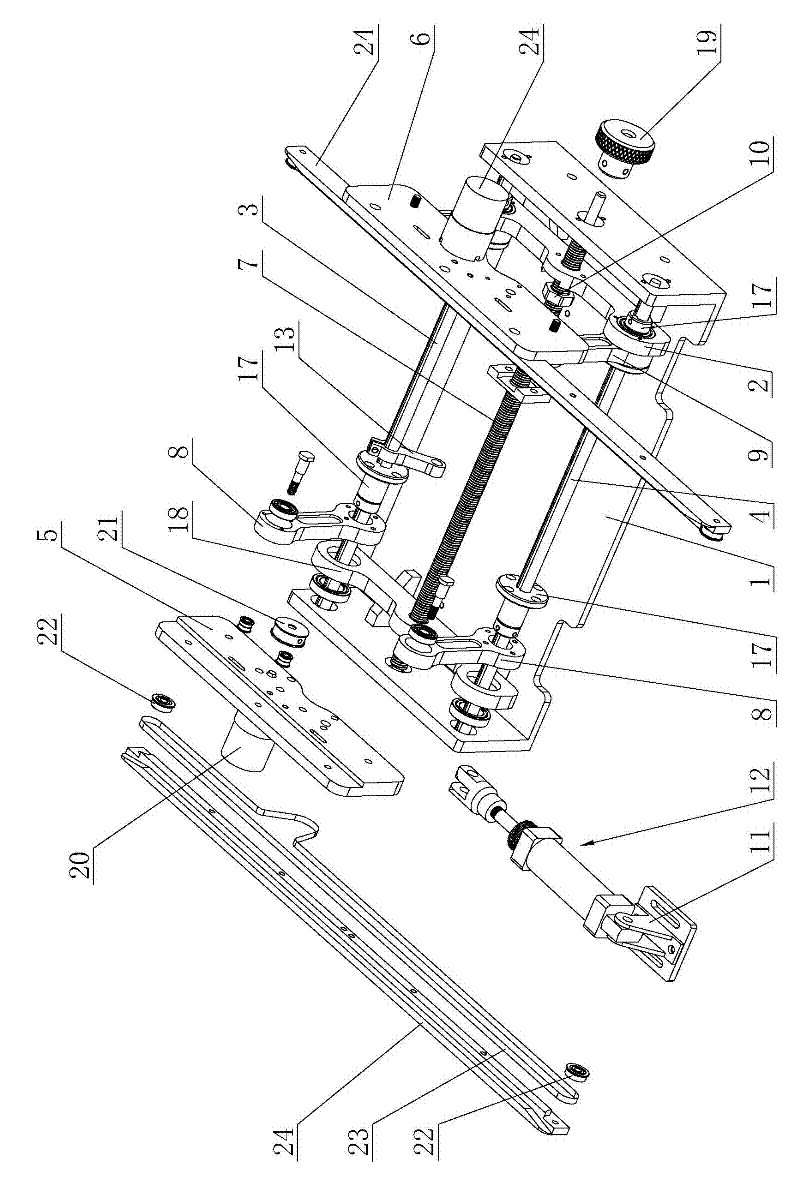

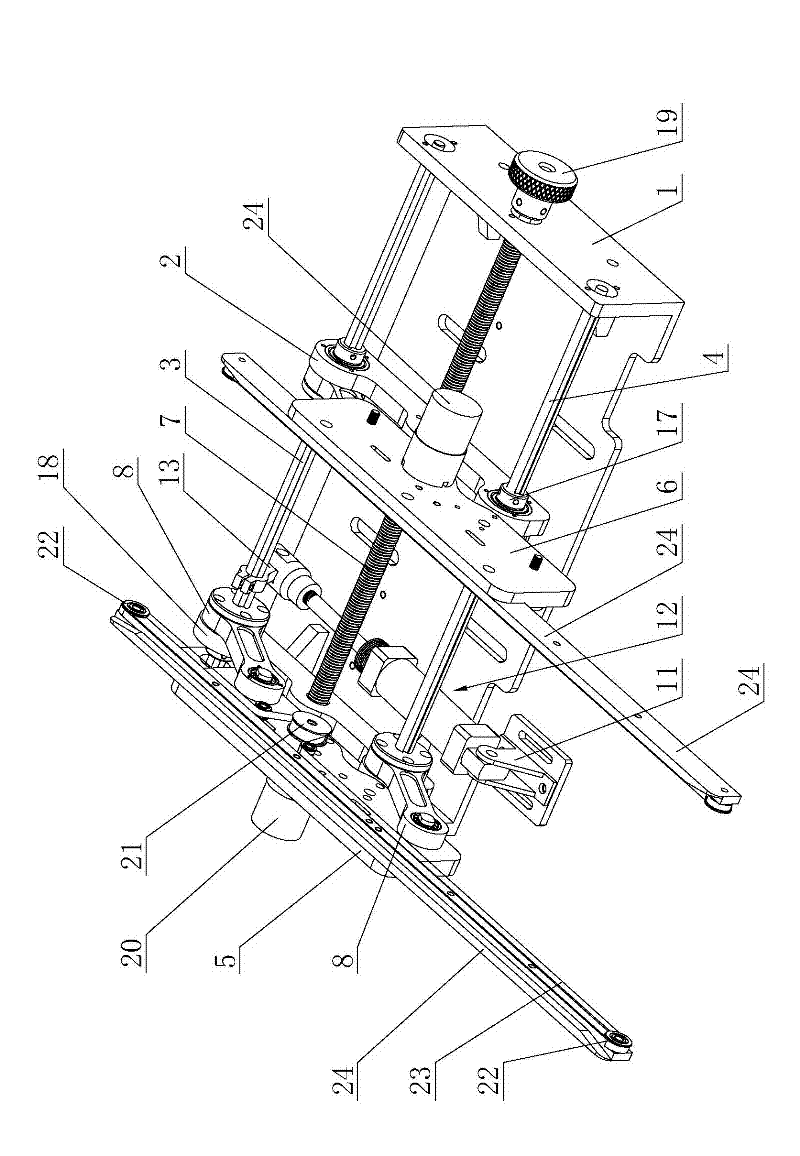

[0020] Such as Figure 1 to Figure 4 Shown is the first embodiment of the parallelogram form connecting platform of the present invention, including the base 1, the movable connecting block 2, the rotating main rod 3 and the balance rod 4 arranged in parallel with the rotating main rod 3, and the two sides of the rotating main rod 3 Both ends of the end and the balance bar 4 are connected to the base 1, and the two ends of the movable connection block 2 are respectively sleeved on the rotating main bar 3 and the balance bar 4, and also include a fixed support plate 5, a movable support plate 6, and an adjustment screw 7 , two transporting devices and a driving mechanism for driving the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com