Gantry crane and hoisting mechanism thereof

A technology of gantry crane and hoisting mechanism, which is applied to walking bridge cranes, cranes, load hanging elements, etc. Weight increase and other issues, to achieve the effect of saving energy, reducing additional bending moment, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

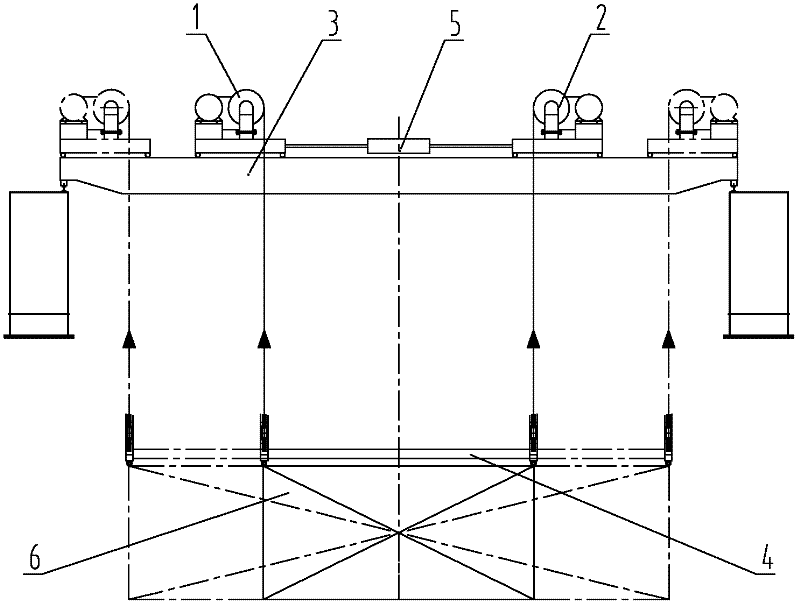

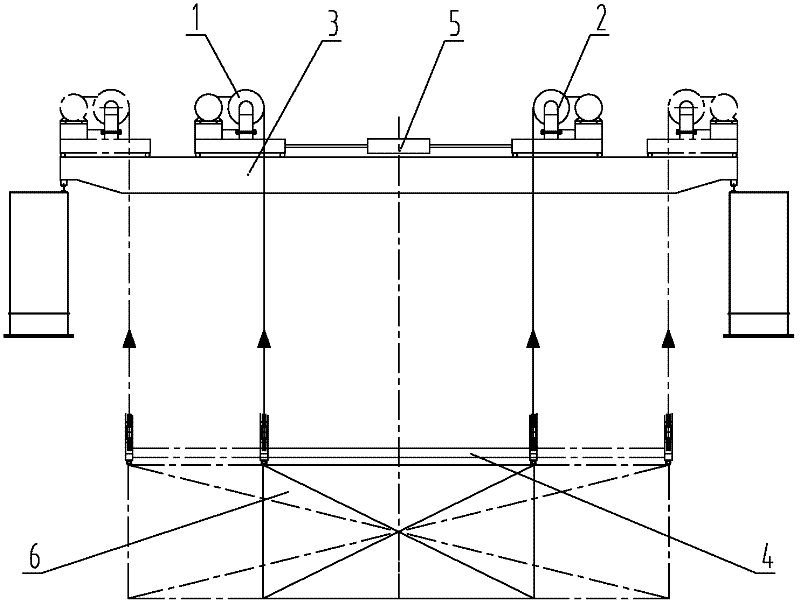

[0025] The core purpose of the present invention is to provide a hoisting mechanism of a gantry crane. In the hoisting mechanism, the additional bending moment on the beam of the spreader is relatively small, and the weight of the spreader is relatively light, which can save energy. In addition, another core of the present invention is to provide a gantry crane including the above-mentioned lifting mechanism.

[0026] Without loss of generality, this article takes the application of the hoisting mechanism on a rail-mounted container crane as an example for introduction. Those skilled in the art should understand that the application of the hoisting mechanism provided in this article to other gantry cranes is not excluded.

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com