Siphon blade type phosphoric acid extractor

An extractor and blade type technology, applied in the field of siphon blade type phosphoric acid extractor, can solve the problems of limited material passing capacity, increased vibration, and easy occurrence of pulses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, to its embodiment, structure, feature and effect thereof of the phosphoric acid purifying device that proposes according to the present invention, describe in detail as follows:

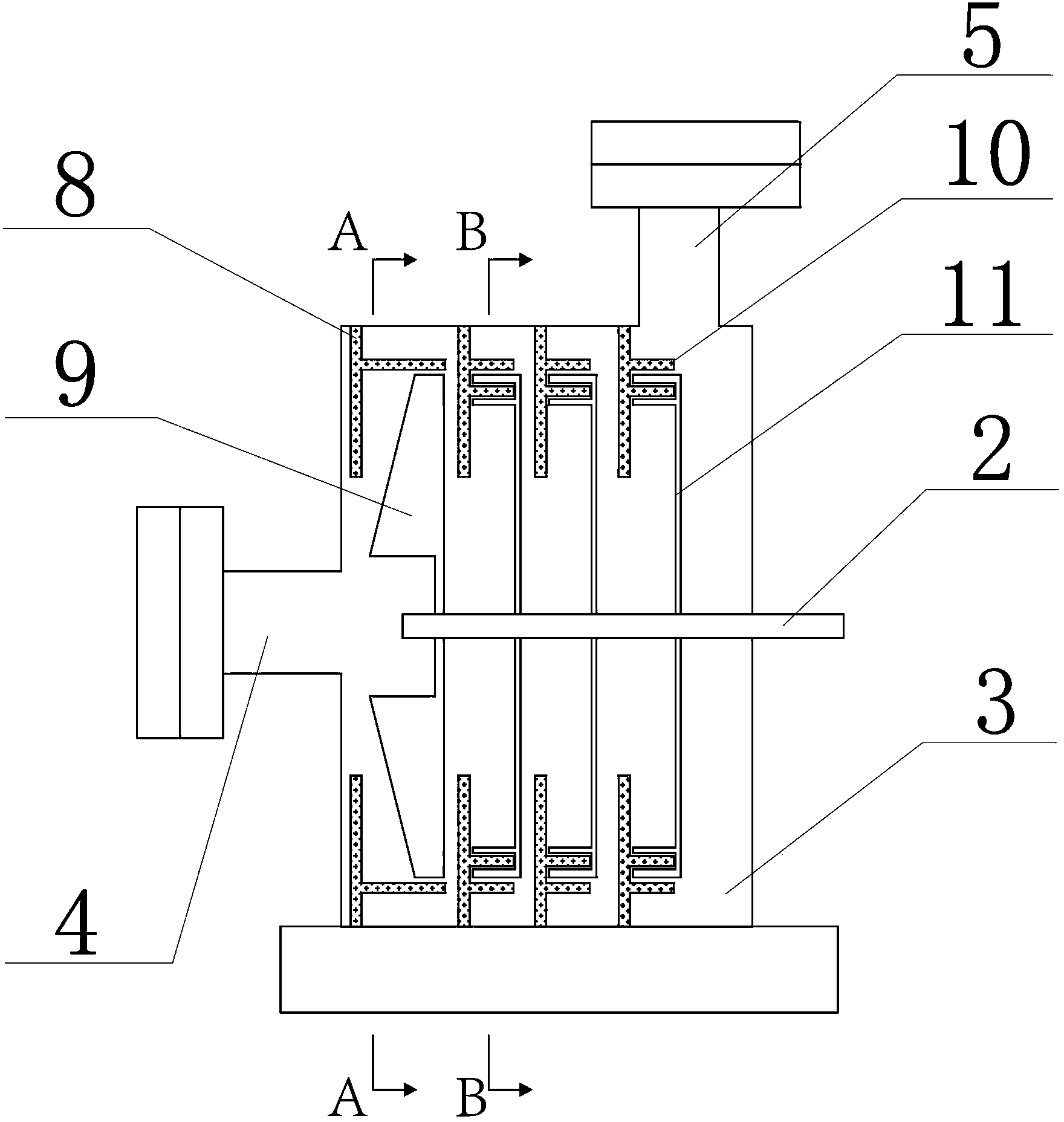

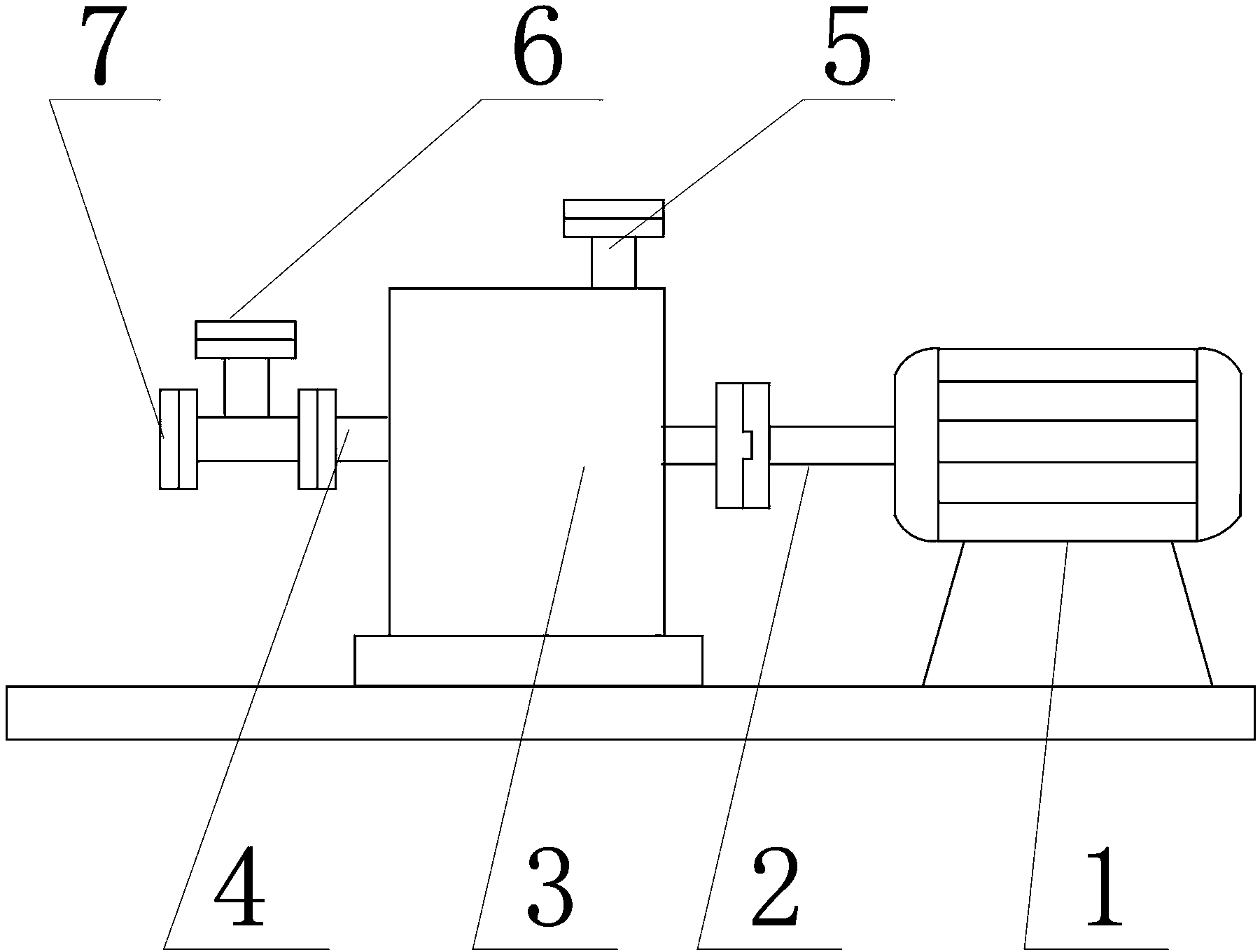

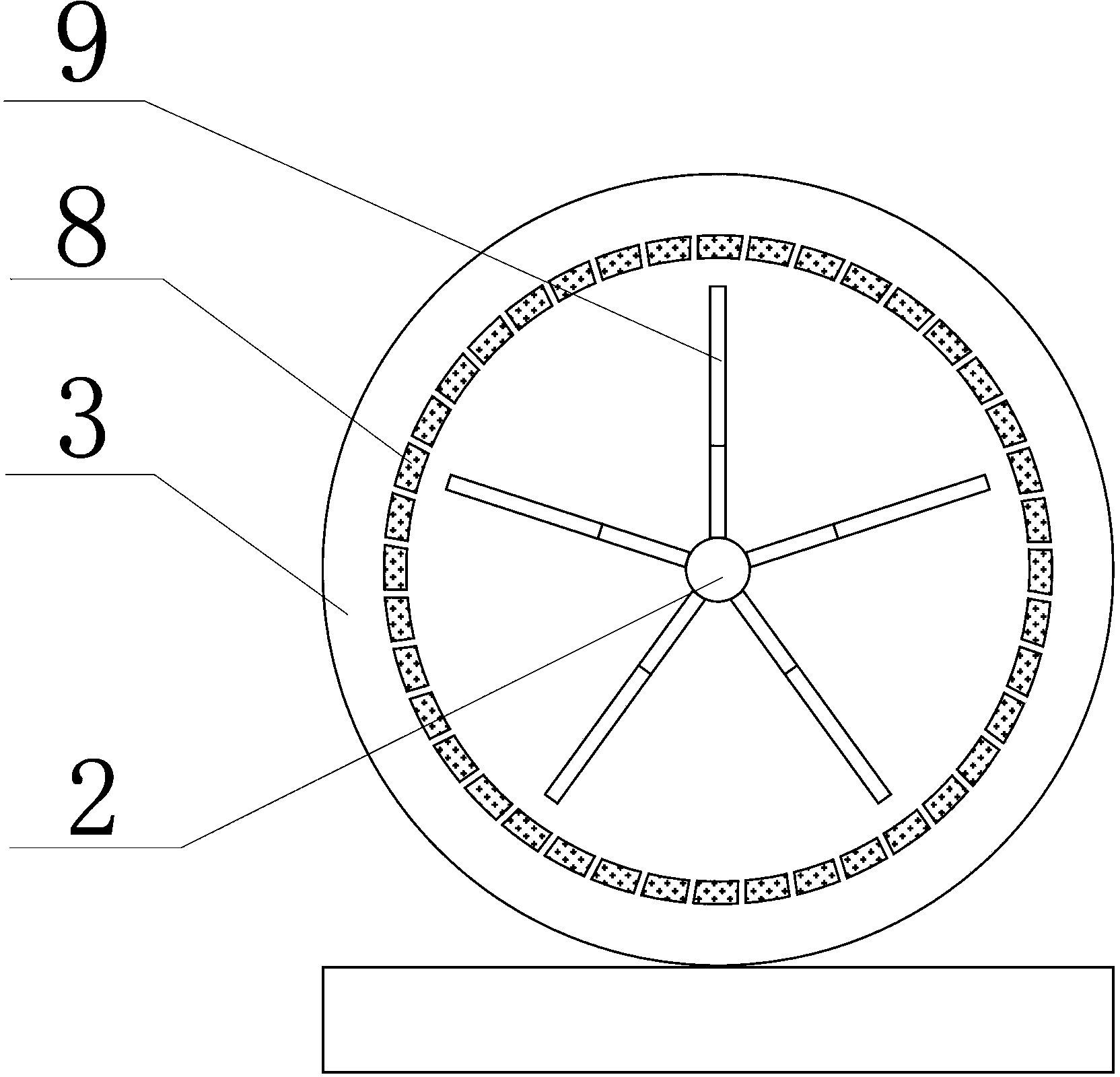

[0018] see Figure 1 to Figure 4 , the siphon blade type phosphoric acid extractor of the present invention comprises: a motor 1, a rotating shaft 2, a working chamber 3, a feeding port 4, and a feeding port 5, the motor 1 and the working chamber 3 are connected by a rotating shaft 2, and the feeding port 4 is located at On the side of the working chamber 3, the discharge port 5 is located on the top of the working chamber 3. The stator A8 and the multi-stage stator B10 are fixed in the working chamber 3. The rotor A10 and the multi-stage rotor B11 are fixed on the rotating shaft 2 in the working chamber 3. The stator A8 and rotor A9 cooperate with each other, multi-stage stator B10 and multi-stage rotor B11 cooperate with each other, and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com