Formula of high temperature-resistant magnesium ferrite orange-yellow pigment and preparation process thereof

A preparation process and technology of magnesium ferrite, applied in the fields of iron compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor thermal stability of ordinary iron oxide yellow pigments, and achieve the effect of excellent dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh 40 grams of industrial-grade activated magnesium oxide and 160 grams of iron yellow filter cake (dry basis) and place them in a 1200ml stainless steel cylinder (Φ100mm*154mm), then add 0.6 grams of sodium silicate additive, add water to dilute to about 600ml, and At room temperature, use high-speed dispersion (dispersion blade diameter Φ50mm, 4500 rpm) for beating, and the mixing time can be controlled at 15 minutes. After suction filtration, drying, roasting reaction (900°C, 30 minutes), and pulverization, an orange-yellow tone high-temperature-resistant magnesium ferrite pigment can finally be obtained.

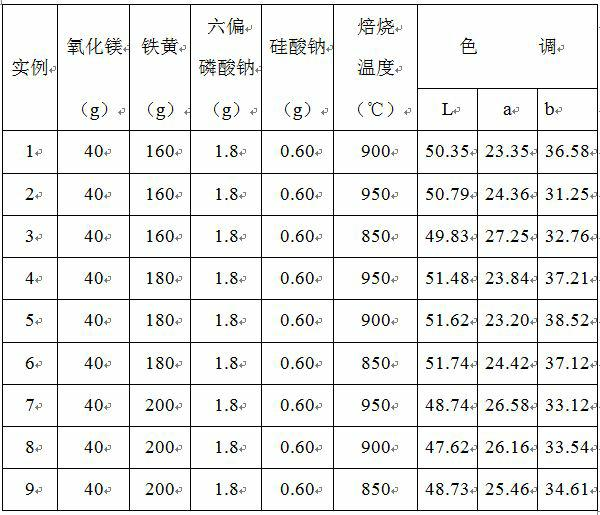

[0015] The following is the final result obtained by the related process of embodiment 1-9 implemented according to the above steps:

[0016] Attachment: Table 1

[0017]

[0018] Table 1 is the measured value of the L, a, b chromaticity system corresponding to this pigment under different formulations and calcination temperature conditions. From the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com