Internal recycle anaerobic membrane bioreactor with single reaction area

An anaerobic membrane biological and reaction zone technology, applied in biological sludge treatment, anaerobic digestion treatment, waste fuel, etc., can solve the problems of small reactor volume and difficult separation of mud and water, achieve high sludge concentration, and eliminate pollution. The effect of mud loss, total volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

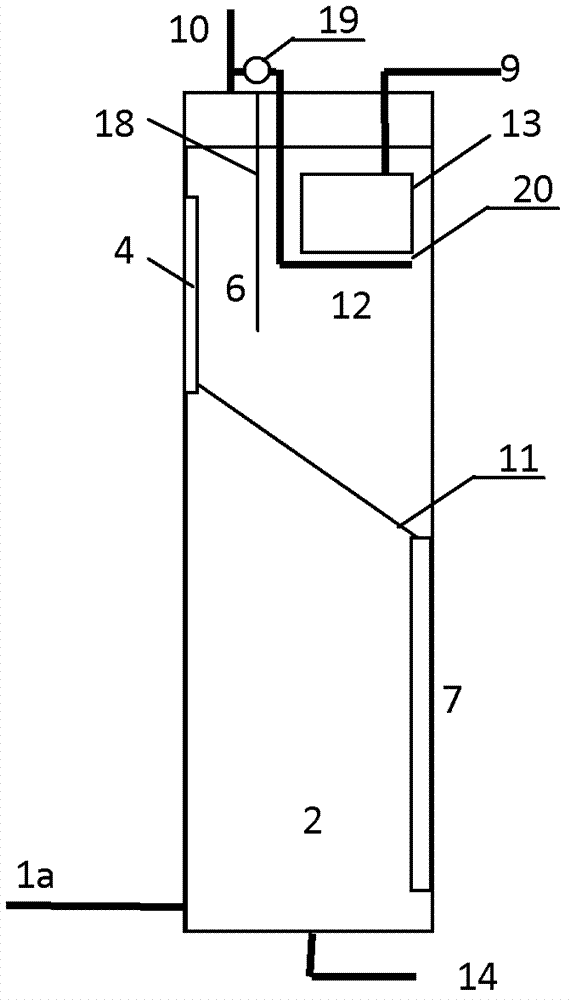

[0015] The structure of the internal circulation anaerobic membrane bioreactor for treating sewage provided by the present invention is as Figure 3a As shown, it contains a reactor body, a water inlet pipe 1a, a water outlet pipe 9, a mud outlet pipe 14 arranged at the bottom of the reaction zone, and a biogas pipe 10 at the top of the reaction zone. The reactor body is provided with a reaction zone 2, a downflow Zone 6, riser 4 and downcomer 7; inside the main body of the reaction zone is provided with a first partition 11, which divides the inside of the main body of the reaction zone into two upper and lower areas, the lower area is the reaction zone 2; The area is provided with a second partition 18, which divides the upper area into a downflow area 6 and a membrane module area 12; the upflow pipe 4 is arranged in the downflow area 6, in the membrane module area 12 A membrane module 13 is provided inside, and the biogas pipe 10 is connected to the gas-water backwashing syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com