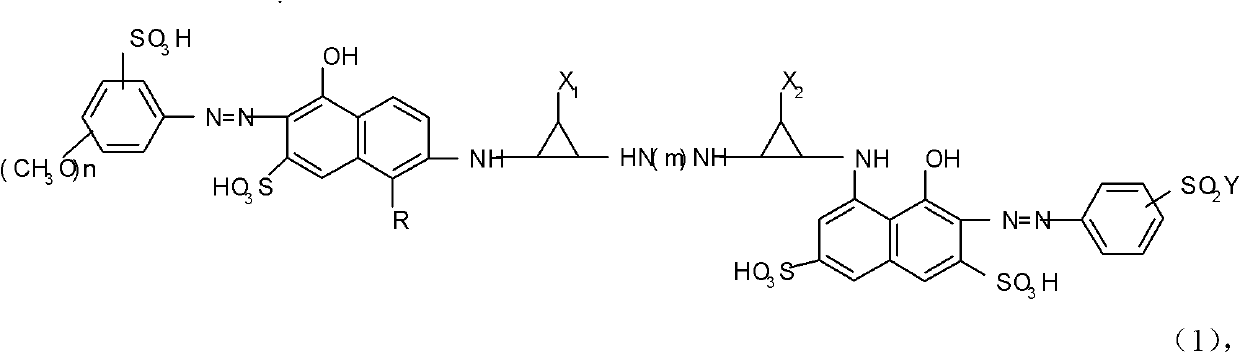

Scarlet azo dye and its preparation and application

An azo dye and dye technology, applied in the direction of azo dyes, reactive dyes, organic dyes, etc., can solve the problem of not meeting the performance requirements, and achieve good light fastness, good wet fastness performance, good light fastness and The effect of perspiration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

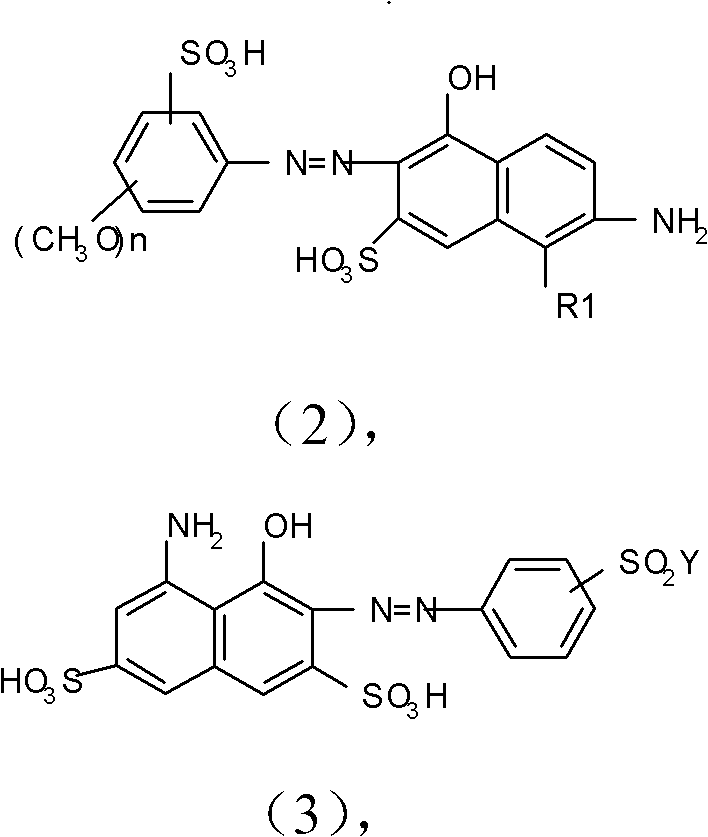

[0025] Example 1, preparation of dyes. Follow the steps below:

[0026] a) Stir in 750 parts of ice water, add 94.5 parts of cyanuric chloride, add wetting agent and 0.5 part of sodium dihydrogen phosphate, and use 32% hydrochloric acid to adjust the mixture to pH = 2.5, and then add 160 parts of carbamide to it The neutral liquid reaction mixture of the compound of the formula is reacted at T=0-2°C, pH=4.5 for 4 hours, then adjusted to pH=6.0-6.5 for 2 hours,

[0027]

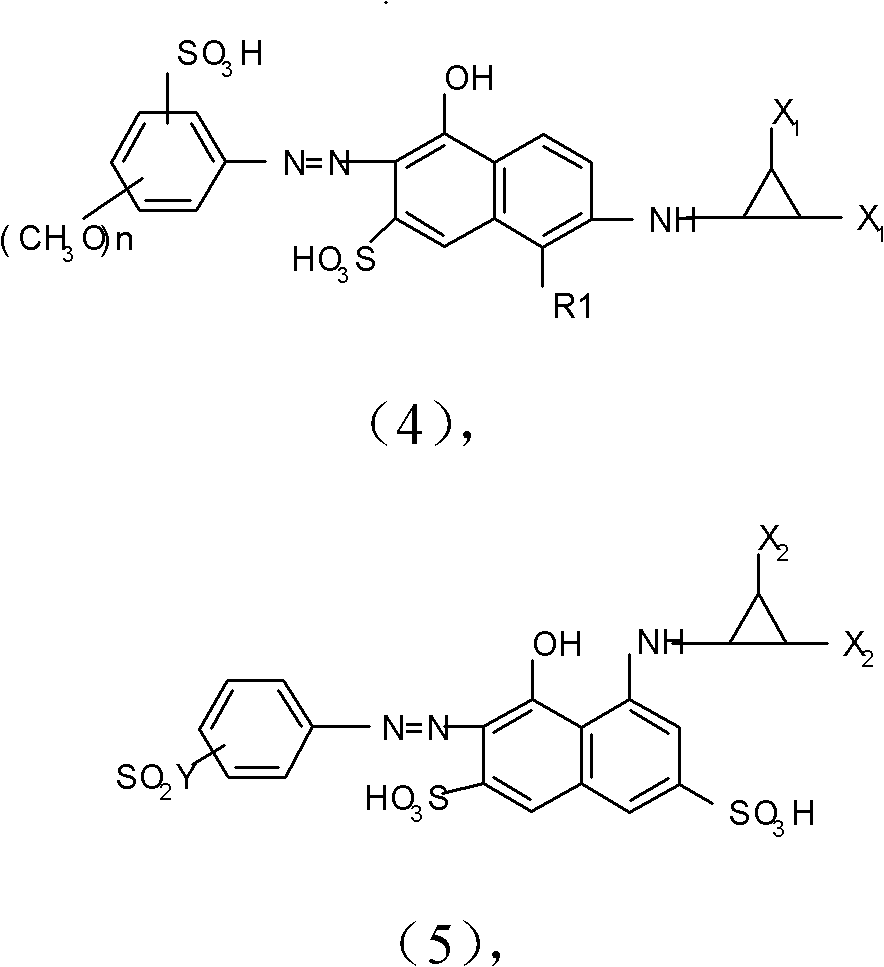

[0028] b) Add 30 parts of ethylenediamine neutral solution to the mixture obtained in step a), adjust pH=6.5 with sodium hydroxide solution, heat to 30° C. and stir for 12 hours.

[0029] c) cooling the neutral liquid of 160 parts of the compound of the following formula to 0°C with ice,

[0030]

[0031] In the case of pH=6.5, cyanuric fluoride was added dropwise, and the reaction was completed for 1 hour.

[0032] d) Add the compound obtained in step b) to the compound obtained in step c), adjust th...

Embodiment 2-10

[0035] Examples 2-10, preparation of dyes.

[0036] The dyestuffs of following formula (1-2) to formula (1-10) can dye cotton fiber red, have good all-around fastness performance, can be obtained in a manner similar to that described in Example 1:

[0037]

[0038]

Embodiment 11

[0039] Example 11, dyeing.

[0040] Staining Step I. 100 parts of cotton fabric are added to a dye bath of 1500 parts containing 45 g / l sodium chloride and 2 parts of the reactive dye obtained according to Example 1 at 60°C. After 45 minutes at 60°C, 20 g / l anhydrous sodium carbonate was added. Continue staining at this temperature for an additional 45 minutes. Stained items are then rinsed, soaped with phenanthrene ionic detergent for a quarter hour at the boil, rinsed again and dried. The above steps can also be dyed at 80°C.

[0041] Staining Step II. 0.1 part of the dyestuff according to example 1 was dissolved in 200 parts of water and 0.5 part of sodium sulfate, 0.1 part of leveling assistant (based on condensation products of higher aliphatic amines and ethylene oxide) and 0.5 part of sodium acetate were added. The pH was then adjusted to 5.5 using acetic acid (80%). The dye bath was brought to 100°C at 50°C for 1 minute, and the dyeing was carried out at this tem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap