Spent catalyst distributor and spent catalyst distribution method for fluid catalytic cracking device

A fluidized catalytic cracking and waiting catalyst technology, applied in catalytic cracking, cracking, petroleum industry, etc., to achieve the effect of good distribution uniformity, less equipment and particle wear, and less impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

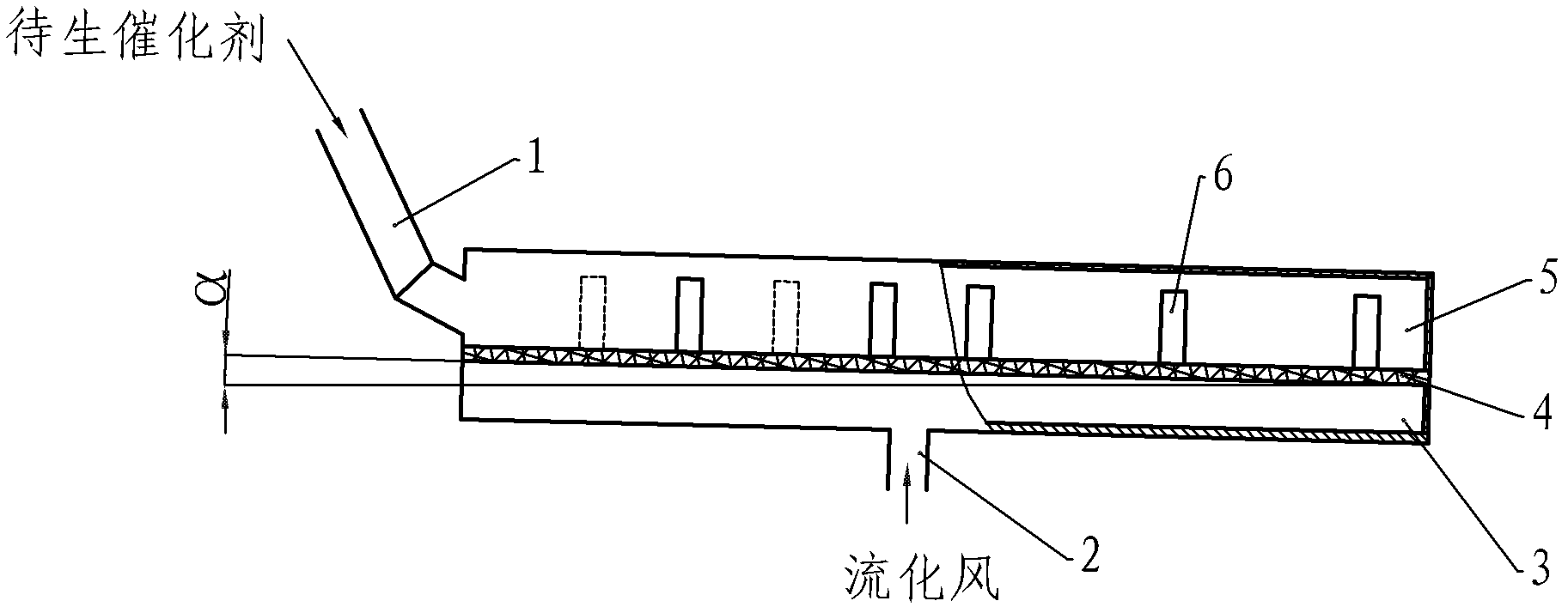

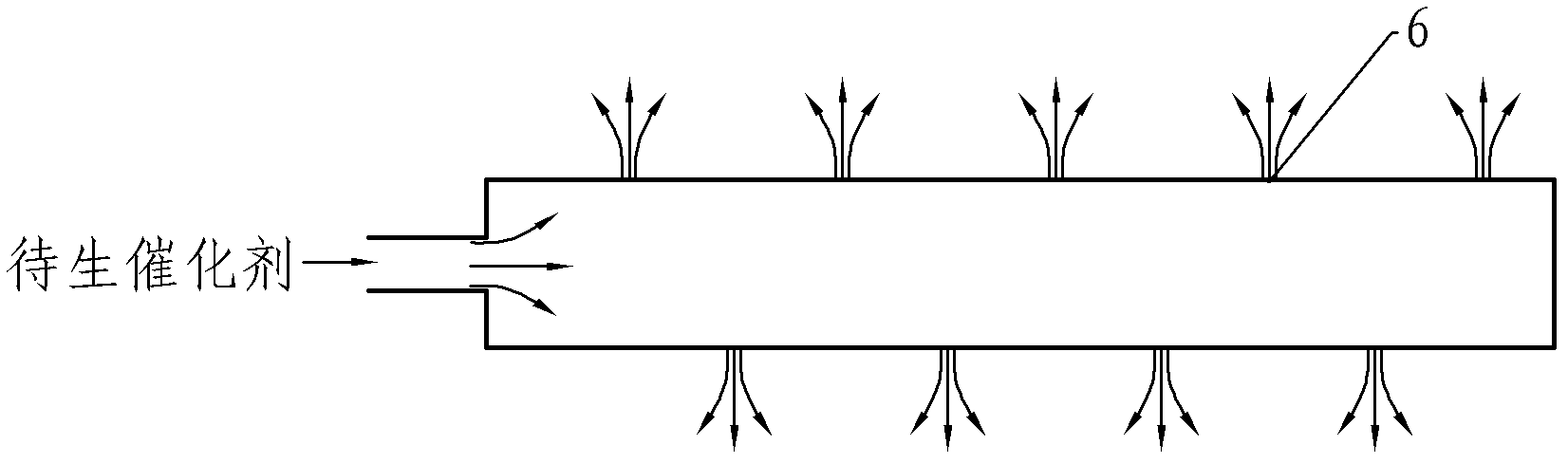

[0042] This embodiment provides a spent catalyst distributor for a fluid catalytic cracking unit, and the distributor includes a plurality of spent catalyst distribution tanks. See Figure 1A and Figure 1B As shown, the structure and distribution principle of the spent catalyst distributor of the present invention are illustrated, and the structure shown in the figure represents a catalyst distribution tank of the spent catalyst distributor in an actual industrial device. in, Figure 1A is the front view, Figure 1B For top view. As shown in the figure, the catalyst distribution tank of the distributor has a double-layer tank structure with an upper tank body and a lower tank body that are basically arranged in parallel. The raw catalyst conveying standpipe 1 is connected, and a plurality of catalyst distribution holes 6 are opened on both sides of the upper tank body; the lower tank body is a fluidizing wind buffer chamber 3, and a fluidizing wind inlet is set to connect w...

Embodiment 2

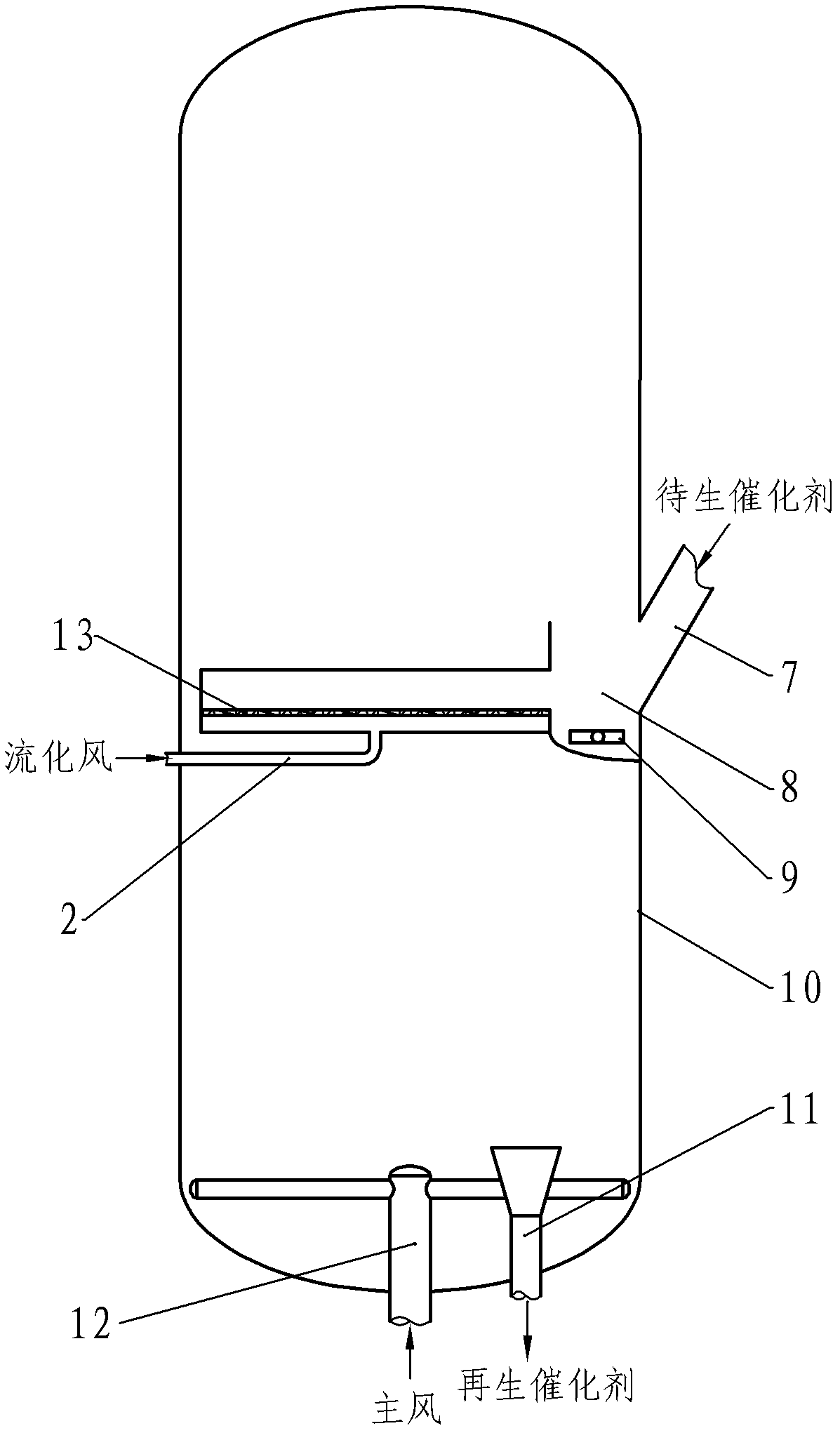

[0045] figure 2 and image 3 It shows an overall structural arrangement of the standby catalyst distributor of the present invention in a parallel catalytic cracking unit. In this embodiment, the standby catalyst distributor is provided with a standby catalyst pre-distribution chamber 8, and multiple standby catalyst distributors The waiting catalyst distribution cavity of the distribution tank 13 is all communicated with the pre-distribution cavity 8, as image 3 shown. Each waiting catalyst distribution tank 13 adopts Figure 1A and Figure 1B In the structure shown, one or more fluidizing air pipes 2 are connected to the fluidizing wind buffer chamber 3 at the bottom. The number and length of the spent catalyst distribution grooves 13 can be determined according to the size of the regenerator 10 to be used, and should cover all cross-sectional areas as much as possible to achieve a more uniform distribution of the spent catalyst. The height of the distributing tank 13 ...

Embodiment 3

[0049] Figure 5 and Figure 6 An overall structural arrangement of the spent catalyst distributor of the present invention in a coaxial catalytic cracking unit is given. In this embodiment, the pre-distribution chamber 14 of the distributor is arranged around the standby standpipe 7 in the regenerator, and the horizontal arrangement of multiple standby agent distribution tanks 13 is as follows Figure 6 As shown, with the pre-distribution chamber 14 as the center, it is distributed radially to the surroundings to basically cover the entire cross-section of the regenerator. Figure 1A and Figure 1B In the structure shown, one or more fluidizing air pipes 2 are connected to the fluidizing wind buffer chamber 3 at the bottom. Such as Figure 5 As shown, a plug valve 17 and a plug valve sleeve 18 are arranged at the outlet end of the spent agent of the standpipe 17 in the regenerator.

[0050] The spent catalyst from the standby riser 7 first enters the plug valve sleeve 18, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com