Adsorption desulfurization method

An adsorption desulfurization and adsorbent technology, which is applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of large fluctuations in the sulfur content of reaction products, etc., and achieve the goal of improving the utilization rate of reaction activity, increasing the sulfur loading capacity, and reducing the regeneration frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

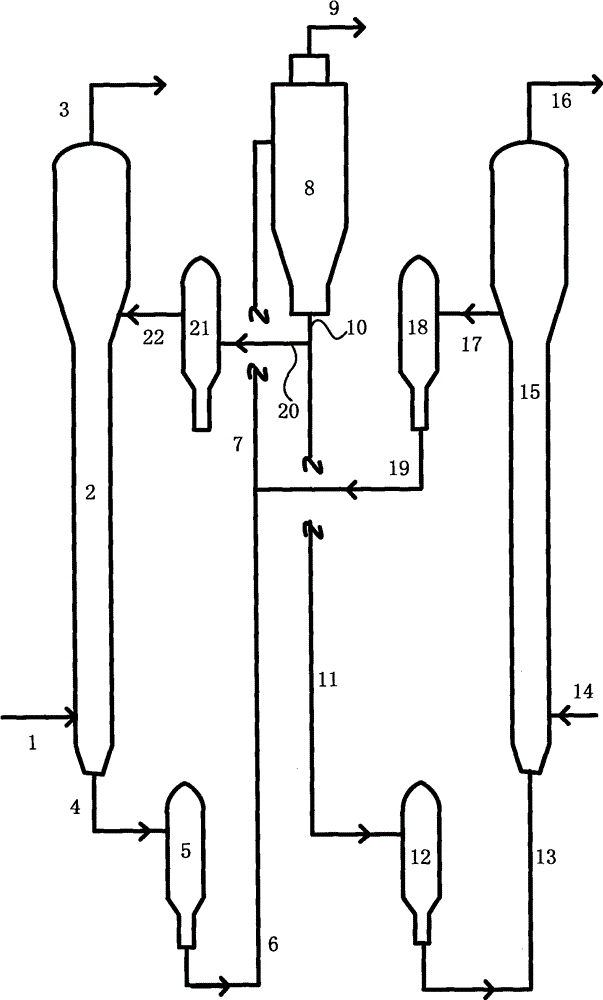

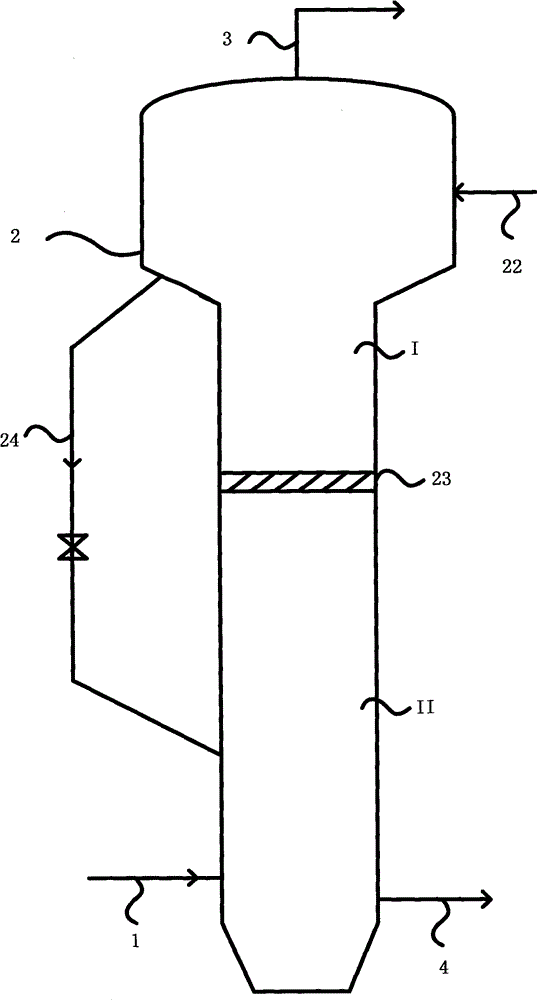

Method used

Image

Examples

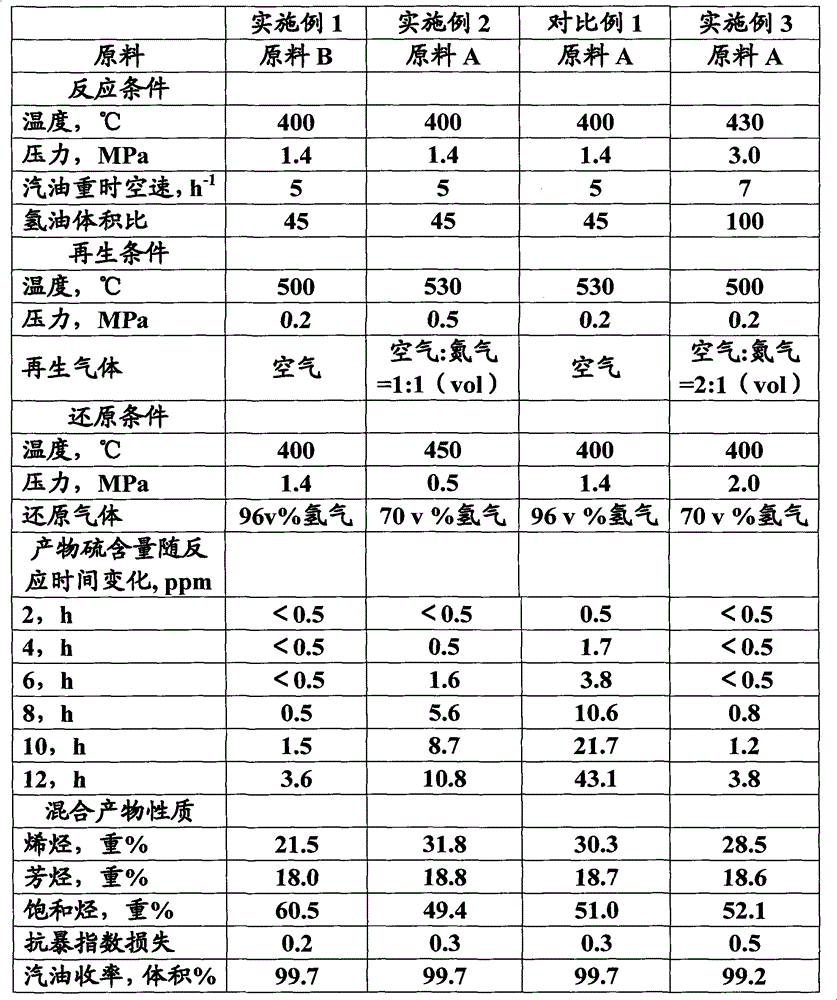

Embodiment 1

[0035] In a fluidized bed reactor with two reaction zones, FCC gasoline raw material B with lower sulfur content is selected as the reaction raw material, and hydrogen is used as the hydrogen supply medium. speed is 5h -1 , react under the reaction conditions of hydrogen oil volume ratio 45, specific reaction conditions are listed in Table 2. The results show that the sulfur content of the reaction product is lower than 0.5ppm (chromatographic detection limit) at the initial stage of the reaction, and as the reaction time progresses, the sulfur content in the product gradually increases, but because the raw material sulfur content is low, only 204.5ppm, so in the reaction At the end, the sulfur content of the product is only 3.6ppm, and because the olefin content of the raw material is also low, the loss of anti-violence index is only 0.2 units.

Embodiment 2

[0037] On a fluidized stretcher with two reaction zones, FCC gasoline raw material A with relatively high sulfur content is selected as the reaction raw material, and hydrogen is used as the hydrogen supply medium. for 5h -1 , under the reaction conditions of hydrogen oil volume ratio of 45, the specific reaction conditions and results are listed in Table 2. Due to the increase of raw material olefin content, the loss of anti-violence index was 0.3 units. Compared with raw material B with lower sulfur content, the sulfur content of raw material A increased significantly, resulting in a rapid rise of sulfur content in the product with the prolongation of reaction time, but still Keep at a low level, the sulfur content of the product is only 10.8ppm at the end of the reaction.

Embodiment 3

[0039] In a fluidized bed reactor with two reaction zones, FCC gasoline raw material A with relatively high sulfur content is selected as the reaction raw material, and hydrogen is used as the hydrogen supply medium. speed is 7h -1 , under the reaction conditions of hydrogen oil volume ratio of 100, the specific reaction conditions and results are listed in Table 2. Due to the increase of reaction pressure and reaction temperature, the sulfur content of the reaction product is only 3.8ppm at the end of the reaction, and the loss of anti-violence index is only 0.5 units. Although a substantial increase in the reaction pressure and reaction hydrogen-oil ratio may lead to an increase in the loss of the anti-violence index, due to the increase in the reaction temperature at the same time, the progress of the hydrogenation reaction is inhibited, and the cracking ability of the adsorbent is enhanced, and the number of small molecular hydrocarbons increases. Therefore, the anti-viol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com