Catalyst system for desulfurization of sulfur-containing hydrocarbons and method for desulfurization of sulfur-containing hydrocarbons

A catalyst and sulfur-containing hydrocarbon technology, which is applied in the catalyst system of sulfur-containing hydrocarbon desulfurization and the field of sulfur-containing hydrocarbon desulfurization, can solve the problems of desulfurization activity and desulfurization stability, affect the implementation effect of sulfur-containing hydrocarbon desulfurization, and incomplete reduction of active metals and other problems, to achieve the effect of improving activity and stability, reducing the heap ratio, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

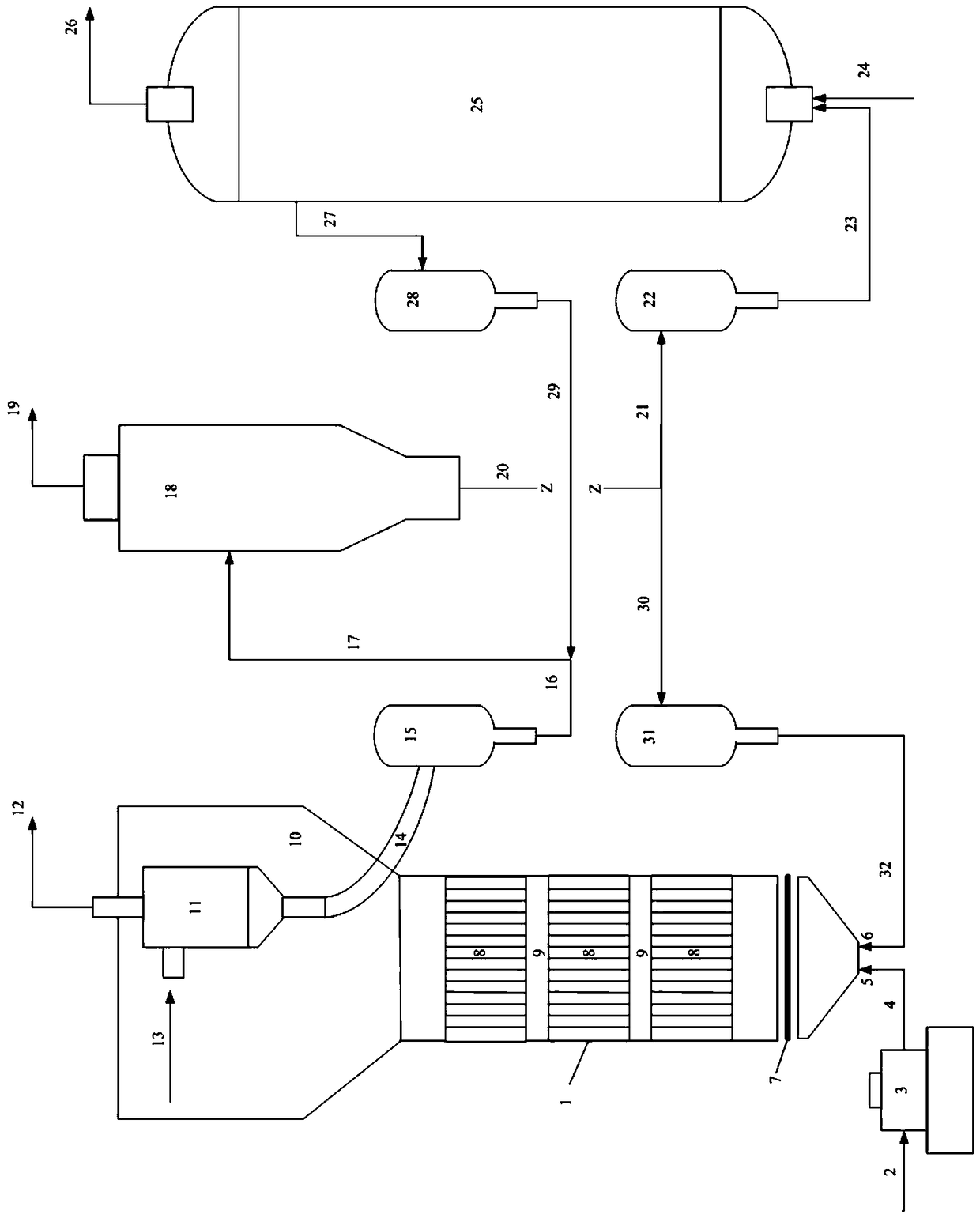

[0066] According to a preferred embodiment of the present invention, preferably, as figure 1 As shown, the method of the present invention is carried out in a device for sulfur-containing hydrocarbon desulfurization, which device includes a sulfur-containing hydrocarbon desulfurization reactor 1, an atmosphere replacement and pressure conversion unit, and a regenerator 25; the bottom of the sulfur-containing hydrocarbon desulfurization reactor 1 Sulfur-containing hydrocarbons and hydrogen donor feed pipes 5 and desulfurization aid feed pipes 6 are provided, and the top of the sulfur-containing hydrocarbon desulfurization reactor 1 is provided with an exhaust pipe 12 and a discharge pipe 14; the atmosphere replacement and change The pressure unit is provided with a reactor receiver 15, a reactor feed tank 31, a regenerator receiver 28, a regenerator feed tank 22, a replacement gas inlet pipe (not marked in the figure) and a replacement gas discharge pipe 19, wherein, The atmosp...

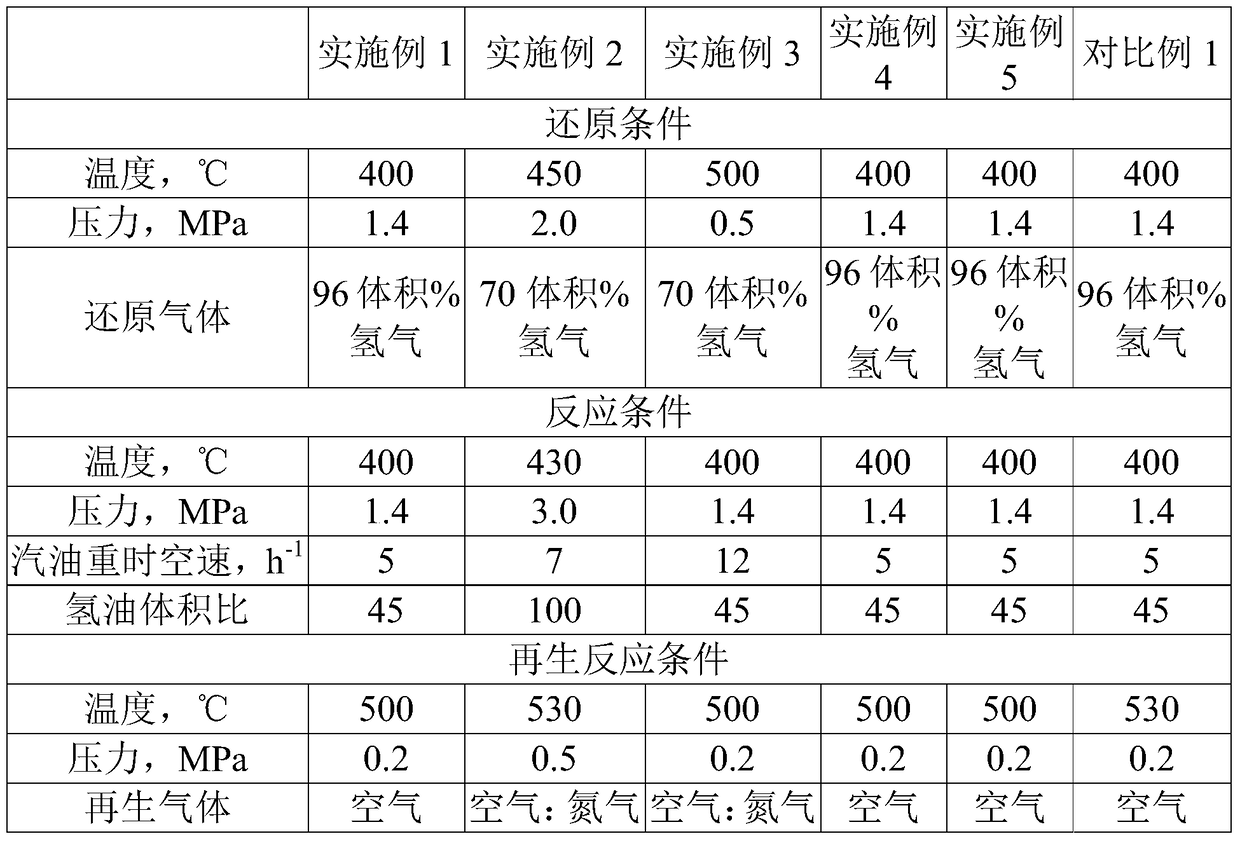

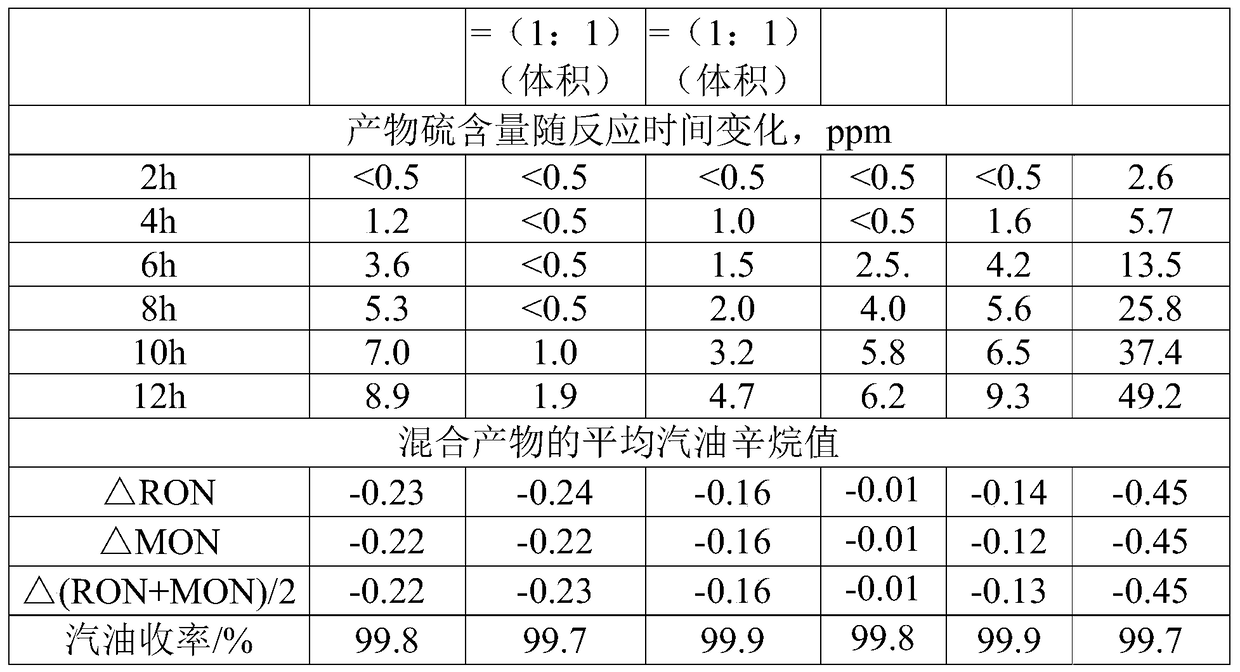

Embodiment 1

[0082] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0083] (1) Catalyst system (the weight ratio of the desulfurization aid to the active component coating of the structured catalyst is 1:1).

[0084] Preparation of Regular Structure Catalysts: Ni / Al 2 o 3 For the active component coating, it is coated on a cordierite honeycomb carrier (the carrier pore density is 400 holes / square inch, and the porosity is 70%) to obtain a regular structure catalyst, and the nickel content on the active component coating is 80% by weight , Al 2 o 3 The content is 20% by weight. The active component coating content of the catalyst was 25% by weight.

[0085] The desulfurization aid is prepared by the following method:

[0086] Mix 6.07 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 6.0 kg on a dry basis), 0.32 kg of lanthanum oxide (produced by Sinopharm Group, co...

Embodiment 2

[0093] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0094] According to the method of Example 1, the difference is that the reduction in (2): use "400°C" and "containing 70% hydrogen by volume" instead of "450°C" and "containing 96% hydrogen by volume"; desulfurization: use " The temperature is 430°C, the pressure is 3.0MPa, and the gasoline weight hourly space velocity is 7h -1 , the volume ratio of hydrogen to gasoline is 100", replacing "the temperature is 400°C, the pressure is 1.4MPa, and the space velocity of gasoline is 5h -1 , the volume ratio of hydrogen to gasoline is 45". The reaction conditions and reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com