Airflow cotton conveying device

A technology of cotton transportation and airflow, which is applied in textiles and papermaking, fiber treatment, fiber feeding, etc. It can solve the problems of complicated procedures and unfavorable long-distance transportation, and achieve the effect of fast transmission speed, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

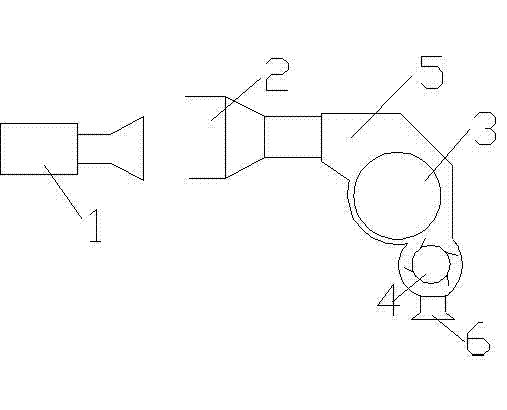

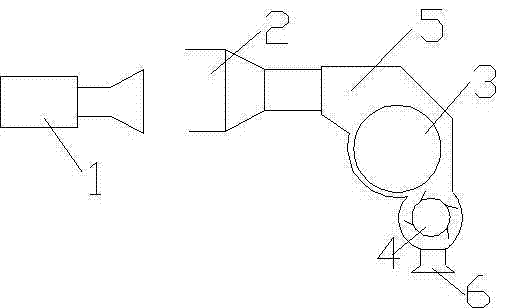

[0011] Such as figure 1 Shown, a kind of air flow cotton conveying device comprises cotton conveying pipe 5, the cotton conveying pipe inlet 2 and the cotton conveying pipe outlet 6 installed at the two ends of described cotton conveying pipe 5, also comprises blower fan 1, is installed in the cotton conveying pipe Dust cage 3 and leather wing beater 4, described leather wing beater 4 is installed under the described dust cage 3, and described blower fan 1 is installed in the front of described cotton delivery pipe inlet 2.

[0012] Cotton enters from the inlet 2 of the cotton delivery pipe. When the fan 1 is working, a negative pressure is formed in the dust cage 3 in the cotton delivery pipe 5, and the cotton clumps entering the cotton delivery pipe condense on the surface of the swirling dust cage 3, and the airflow carries dust Impurities such as cotton wool and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com