Central cutter mechanism for automatic bag-opening parallel sewing machine

A lockstitch machine, center knife technology, applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of rough cutting resolution, increase safety hazards, reduce mechanical performance, etc., and achieve high practical value and safe use. High stability and the effect of preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

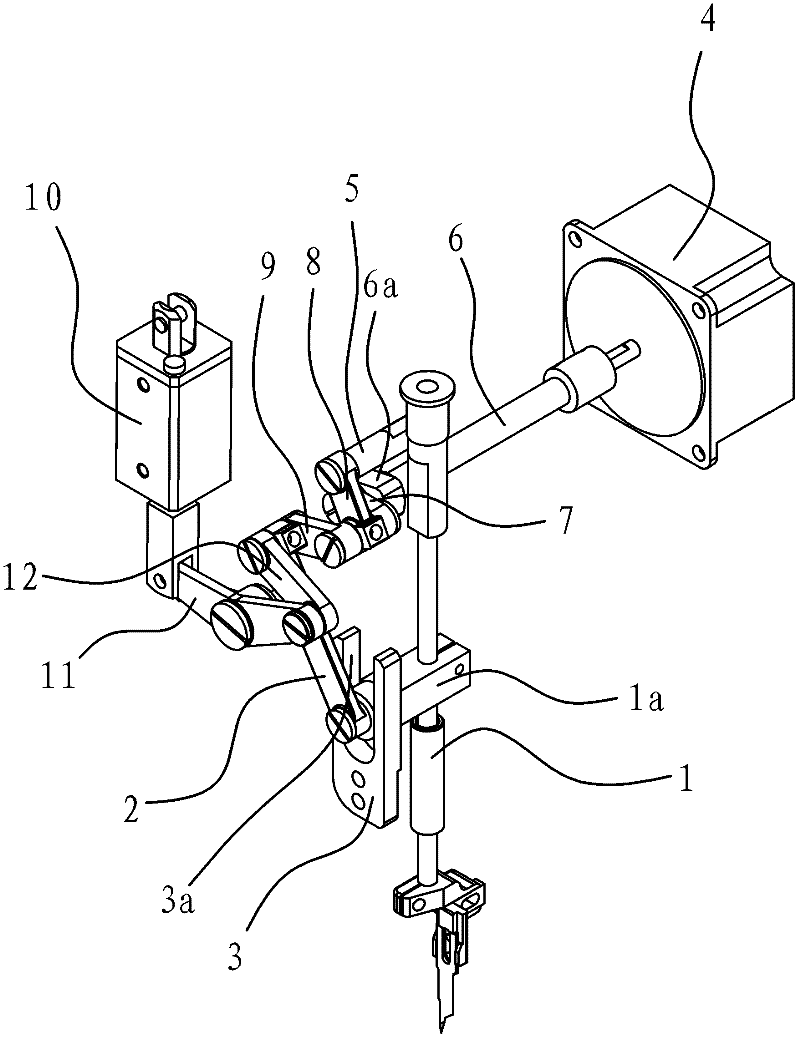

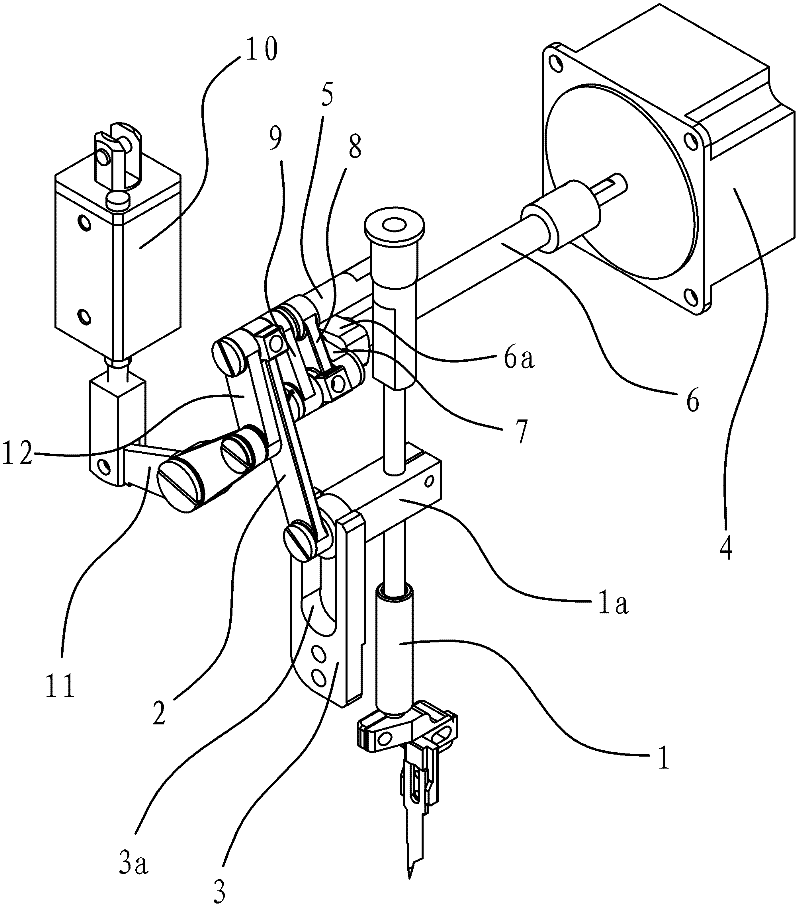

[0029] A lockstitch sewing machine is mainly a machine that uses a sewing thread to form a stitch on the sewing material to interweave or sew one or more layers of sewing material. Such as figure 1 with figure 2 As shown, the central cutter mechanism of the automatic bag opening lockstitch sewing machine is arranged on the body of the bag opening lockstitch sewing machine, and it is connected with the center knife bar of the bag opening lockstitch sewing machine.

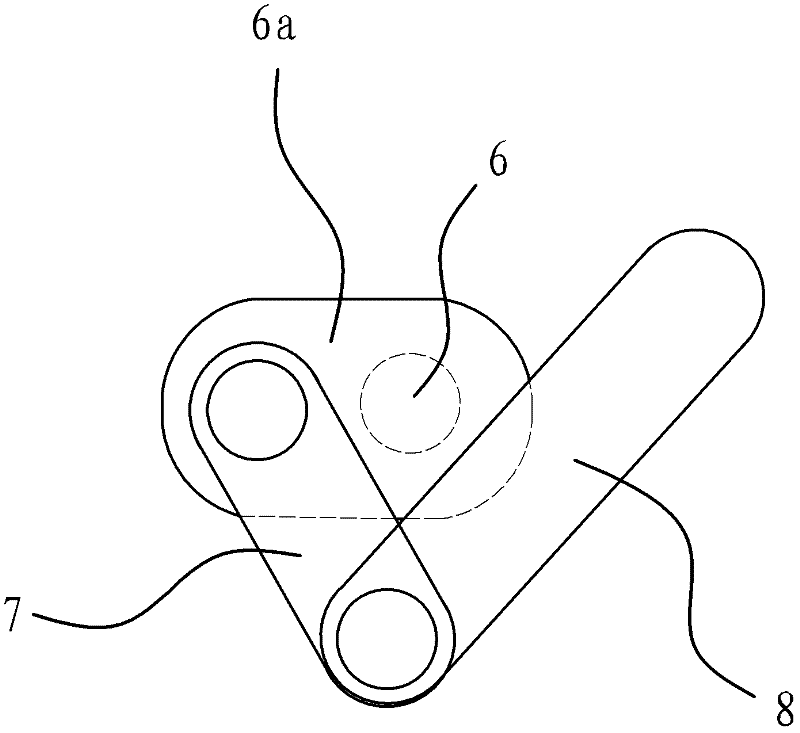

[0030] The mechanism includes a cutter connecting rod 2, a driving mechanism and a clutch mechanism. One end of the cutter connecting rod 2 is hinged on the center knife rod 1, and the other end of the cutter connecting rod is connected with the driving mechanism. The knife link drives the center knife bar 1 to move up and down reciprocally, and the clutch mechanism is connected with the cutter link 1 and the clutch mechanism can drive or not drive the center knife bar 1 to move back and forth during the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com