Double-oil cylinder synchronous system for bridge detection operation vehicle

A synchronous system and bridge detection technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of asynchronous double cylinder drive, uncontrolled deployment speed, damage to the working platform, etc., to avoid damage and prevent chattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

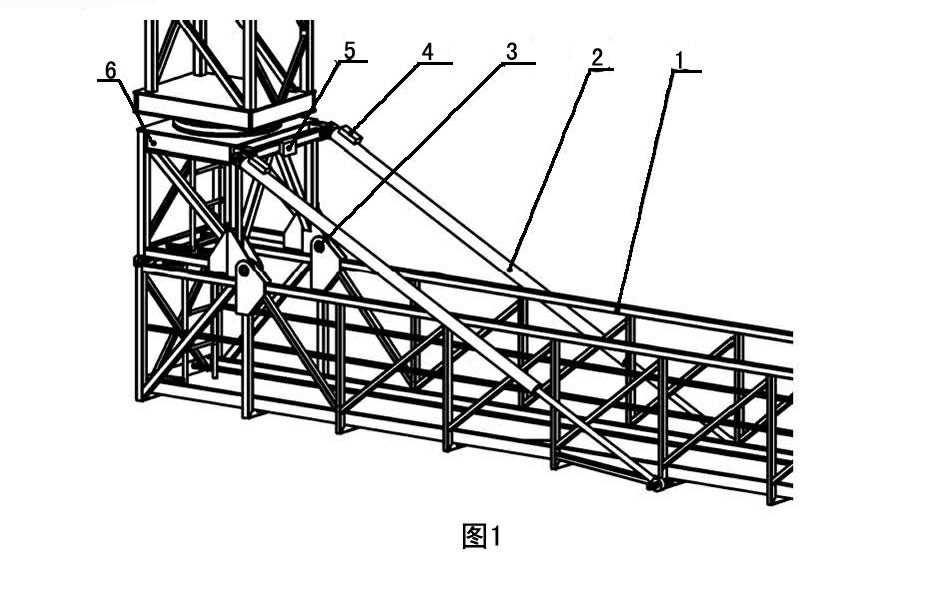

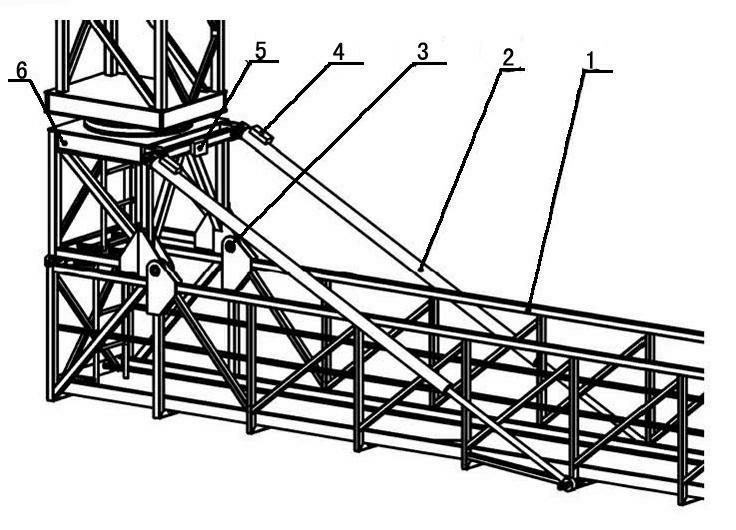

[0014] Such as figure 1 , a dual-drive cylinder synchronization system for a bridge inspection vehicle. The two ends of the drive cylinder 2 are respectively hinged with the fixing seat 6 and the U-shaped cross-section work platform 1. Under the action of the drive cylinder 2, the work platform 1 can go around its two sides. The hinge shaft 3 that the top is connected with the fixed seat 6 rotates to complete the retracting action.

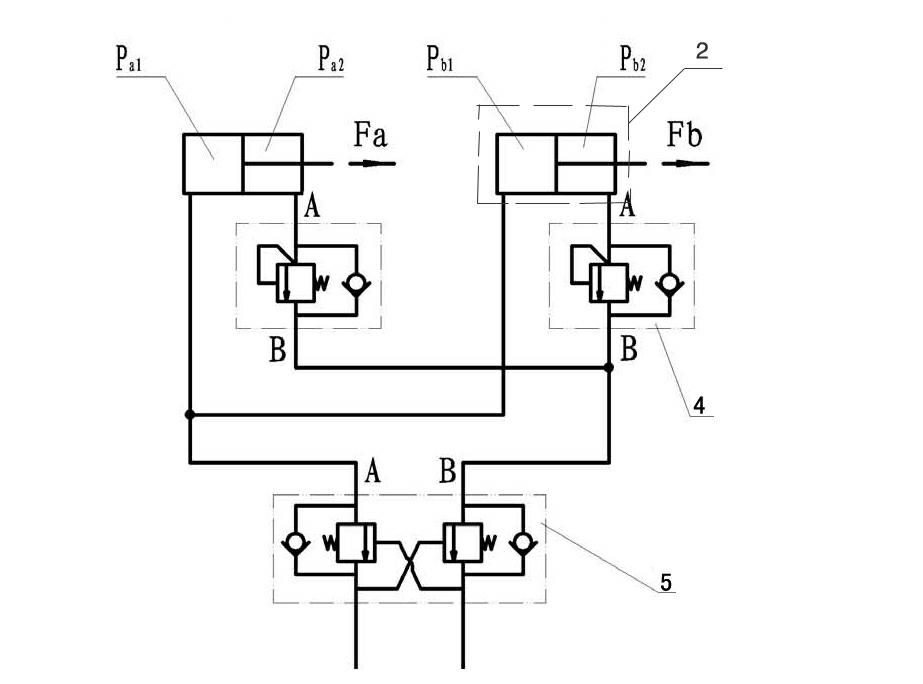

[0015] Such as figure 2 , the system at least includes a double drive cylinder 2, a balance valve 5 and two one-way back pressure valves (groups) 4 that individually adjust the back pressure, the double drive cylinder is a double-acting drive cylinder, the two drive cylinders and their oil circuit connections For parallel connection, the one-way back pressure valve is respectively connected between the oil port of the rod chamber of the two driving cylinders and the working oil port of the balance valve, or connected between the oil port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com