Impeller of centrifugal fan and centrifugal fan

A centrifugal fan and impeller technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of low aerodynamic efficiency and high energy consumption, so as to reduce operating energy consumption, increase effective power, and reduce flow channels Effect of Blocking Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the centrifugal fan impeller and the centrifugal fan provided by the embodiments of the present invention will be described below with reference to the drawings in the description.

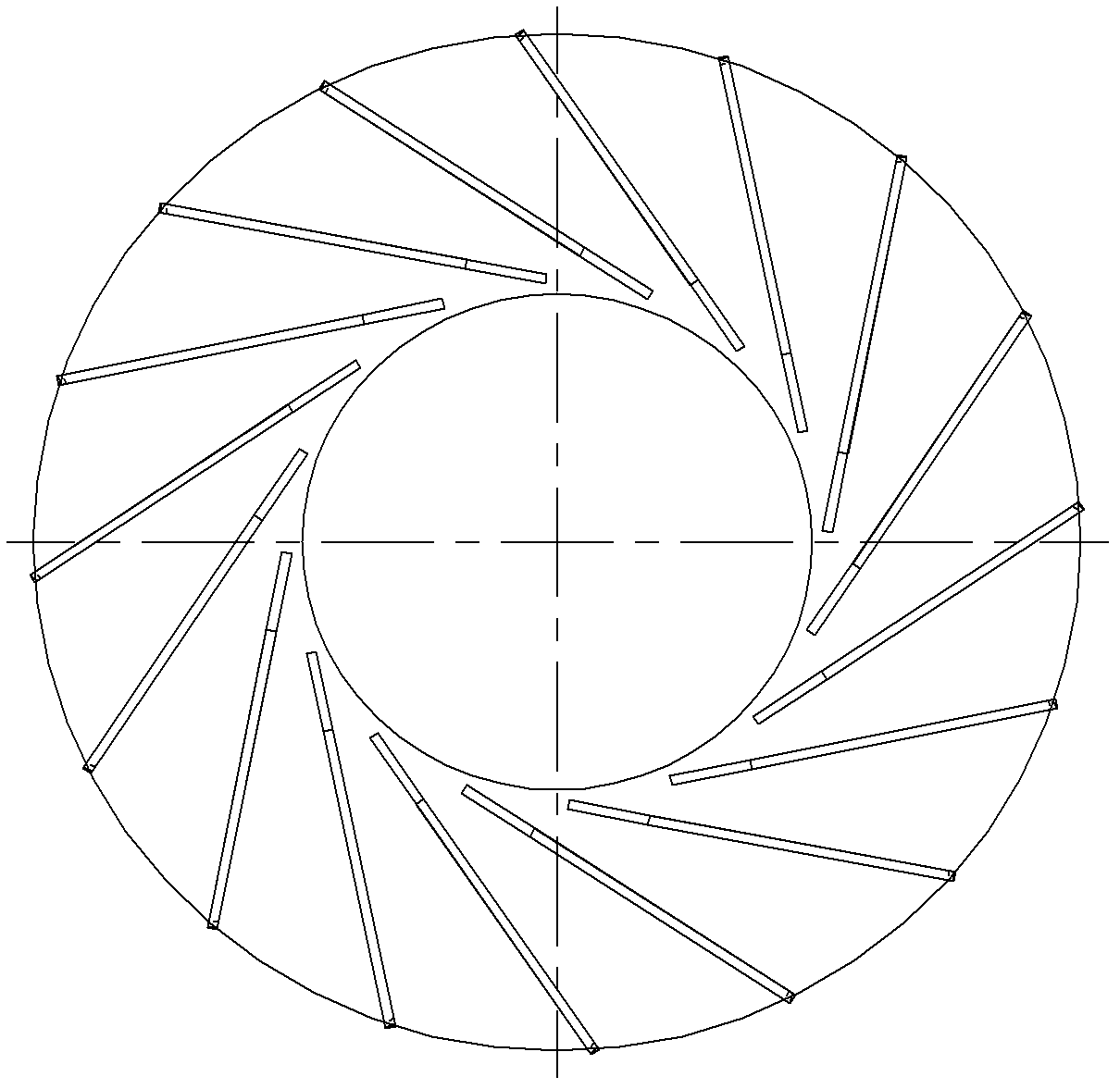

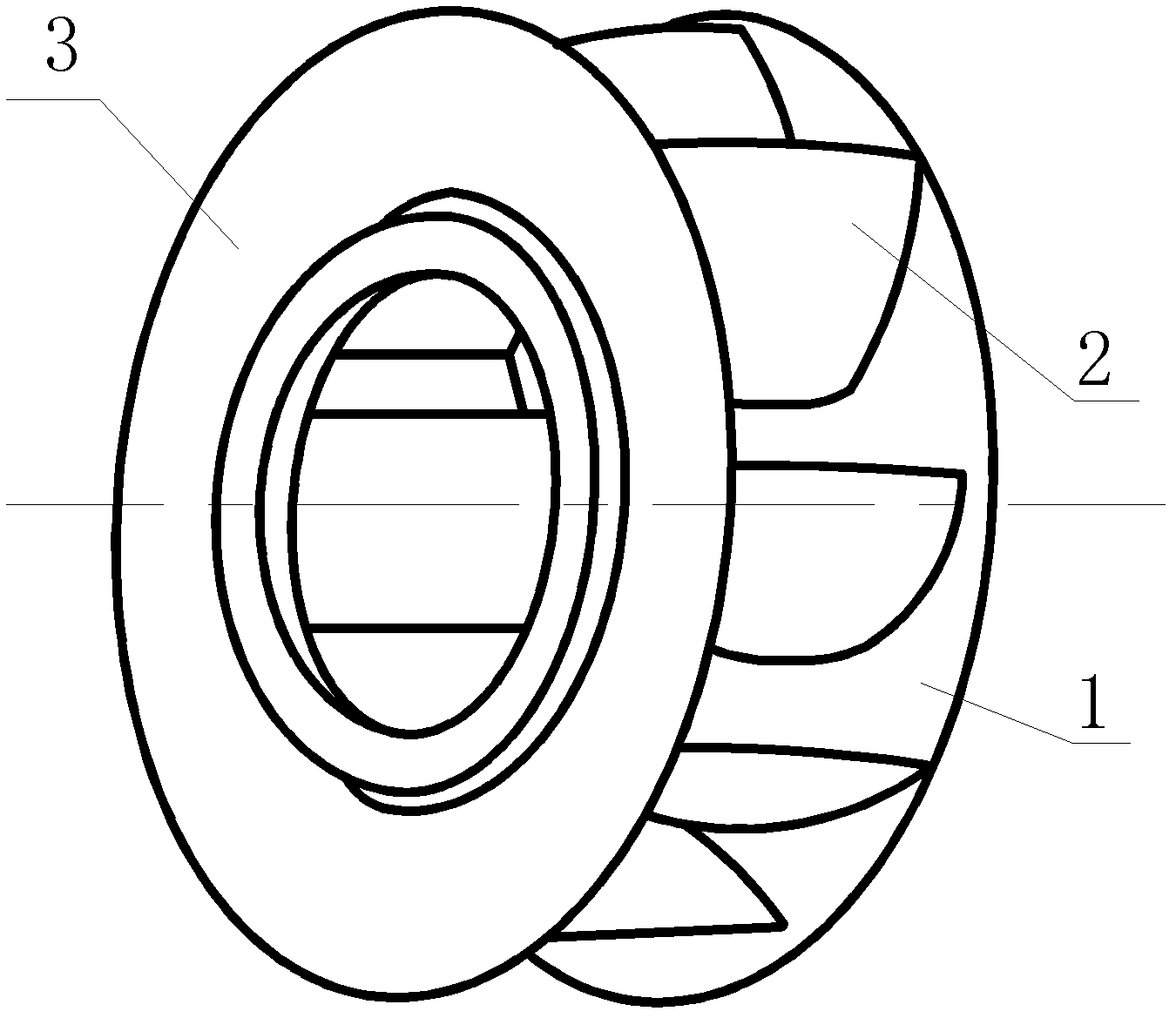

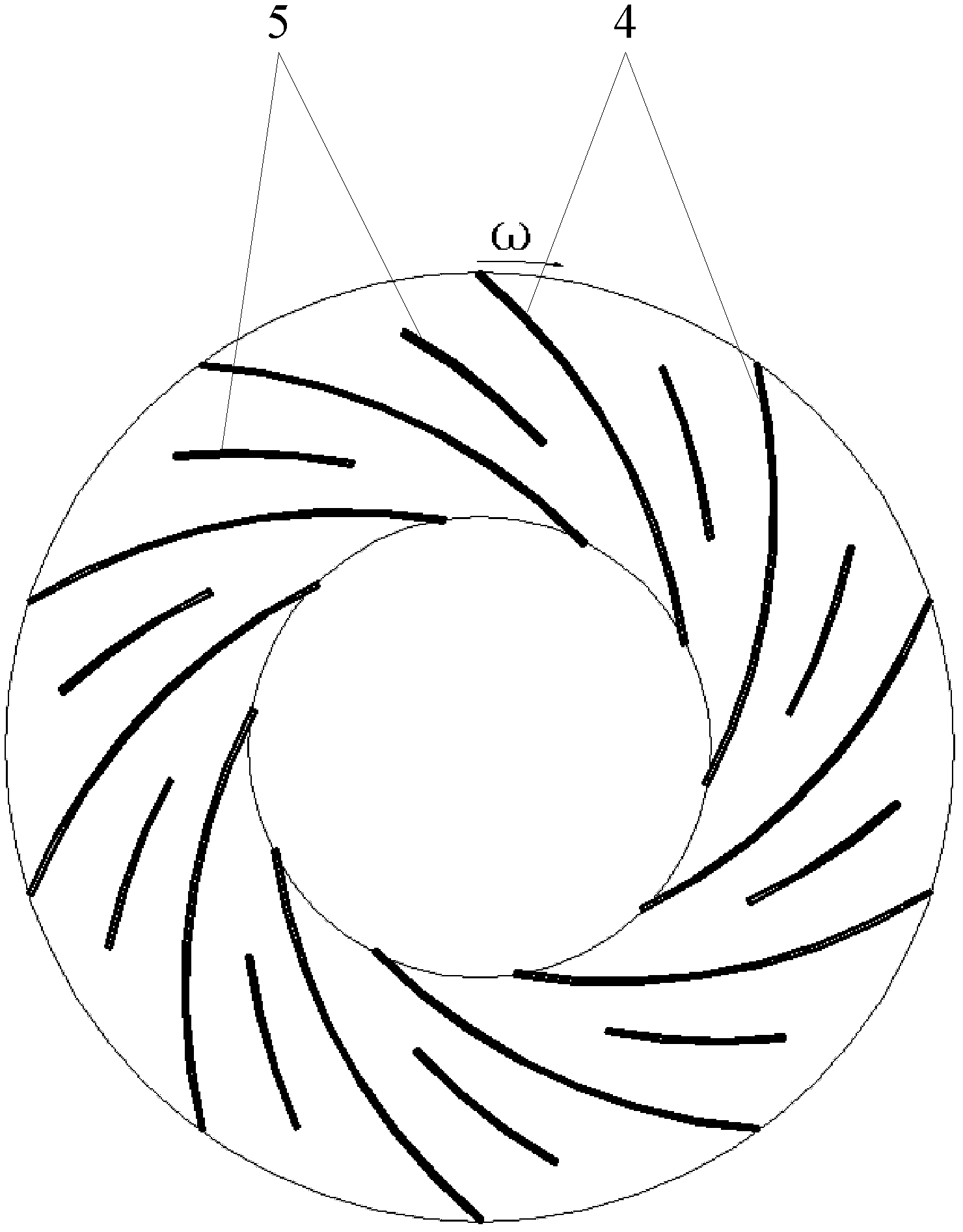

[0028] The centrifugal fan impeller provided by the embodiment of the present invention, such as figure 2 Shown is similar to the prior art, including: hub 1, blade 2 and wheel cover 3 parts, blade 2 is installed between hub 1 and wheel cover 3, the difference is that the embodiment of the invention is for the existing centrifugal fan impeller The blades have been improved, image 3 Shown is a schematic diagram of the overall structure of the blade of the centrifugal fan impeller provided by the embodiment of the present invention, from image 3 It can be seen that the impeller of the centrifugal fan provided by the embodiment of the present invention provides two types of blades, namely the backward long blade 4 and the backward short blade 5, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com