Infrared heating plate made of carbon fiber composite materials

A composite material and carbon fiber technology, which is applied in the direction of gas fuel burners, lighting and heating equipment, combustion methods, etc., can solve problems in the field of gas infrared burners, and achieve the effect of ensuring production quality and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

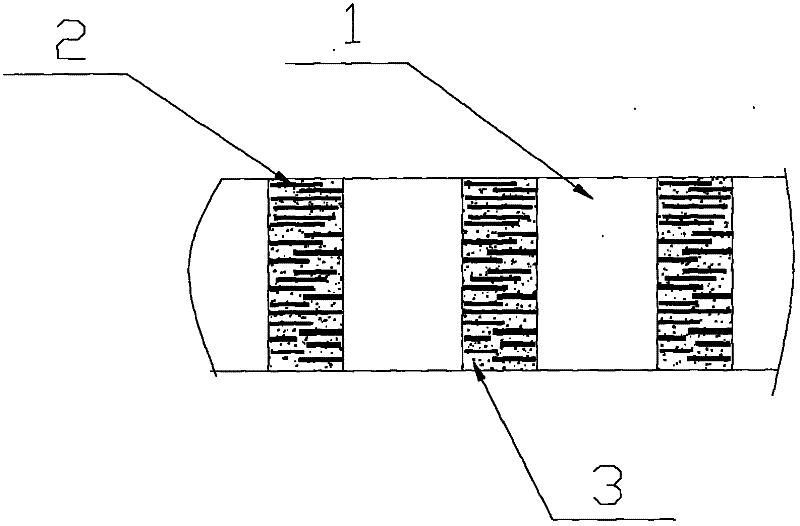

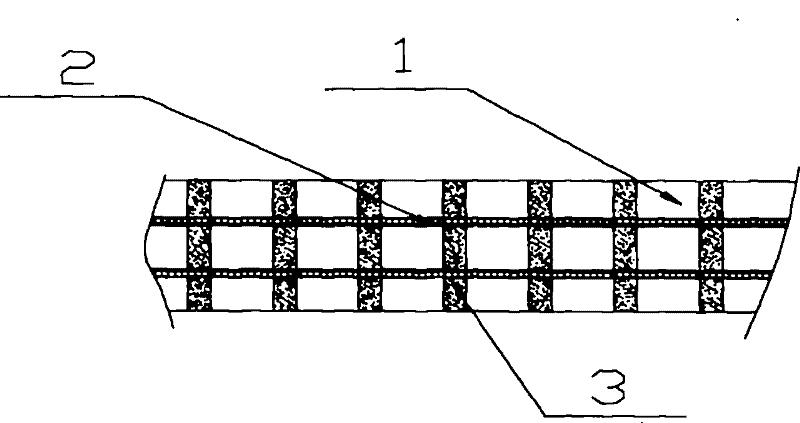

[0024] Such as figure 1 As shown, the carbon fiber composite infrared heating plate is composed of a honeycomb structure, the honeycomb holes 1 are round or square holes and arranged in an orderly manner, and the shape is round or rectangular; the honeycomb structure of the carbon fiber composite infrared heating plate It is composed of base material, aggregate and auxiliary materials, the base material is ceramic material, the aggregate 2 is carbon fiber filaments with a length of 1-6 mm, and the auxiliary materials include at least bonding materials and lubricating materials , the carbon fiber filaments are dispersed in the mixture body 3 formed after the base material and auxiliary materials are mixed.

Embodiment 2

[0026] Such as figure 1 As shown, the carbon fiber composite material infrared heating plate is composed of a honeycomb structure. The honeycomb holes 1 are round holes or square holes and are arranged in an orderly manner. Composite auxiliary materials, the base material is ceramic material, the aggregate 2 is a carbon fiber mesh with a mesh size greater than 0.5 mm, the auxiliary materials include at least bonding materials and lubricating materials, and the carbon fiber mesh is double-layered The shape is placed in the mixed material body 3 formed after the base material and the auxiliary material are mixed, and is surrounded by the mixed material body 3 .

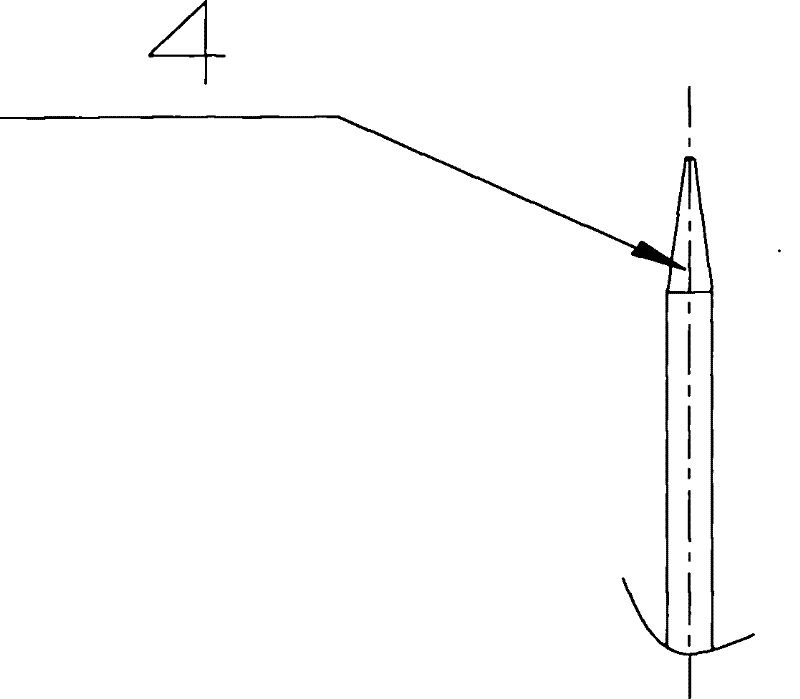

[0027] In the above embodiments, the carbon fiber composite material infrared heating plate is formed by molding or extrusion, and on the forming die, the top 4 of the steel needle used to form the honeycomb hole is in the shape of a cone.

[0028] In the above embodiments, far-infrared materials or combustion catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com