Air and clinker leakage preventing grate cooler module

A grate cooler and air leakage prevention technology, applied in the field of grate cooler modules, can solve problems such as leakage, poor adaptability, and air leakage, and achieve the effects of low power consumption, reduced wind resistance, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present technology will be further described below through the embodiments in conjunction with the accompanying drawings.

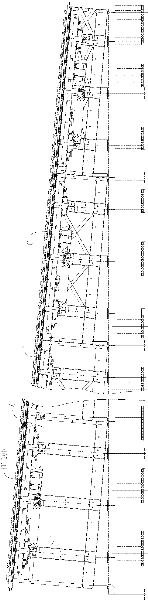

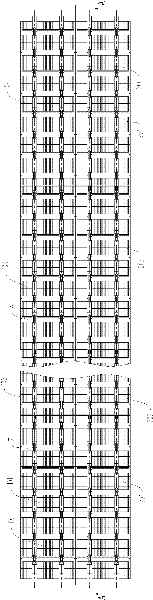

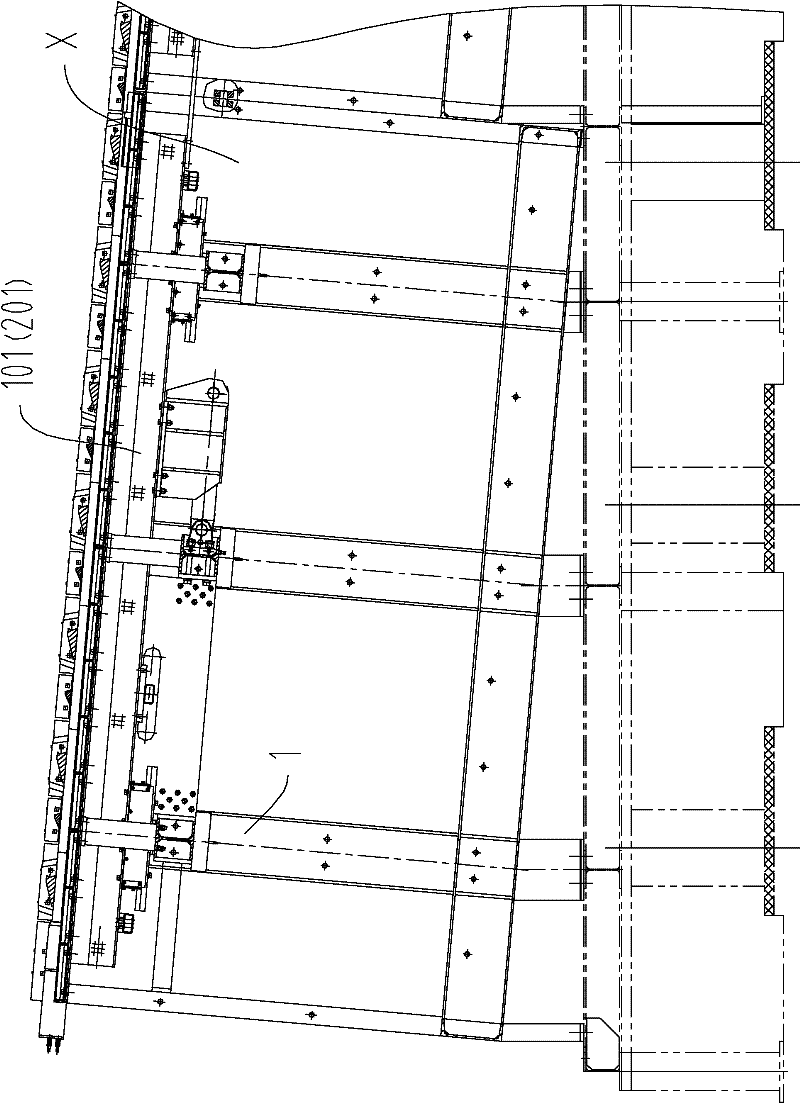

[0042] Such as figure 1 , 2 The grate cooler shown comprises two rows of parallel module groups 100, 200 arranged in the transverse direction, and the trays in the two rows of module groups are in contact with each other through a sealing plate between the two rows of module groups. From left to right, the module group 100 is composed of four grate cooler modules 101, 102, 103, 104 in series in the longitudinal direction, and the module group 200 is formed by the four grate cooler modules 201, 202, 203, 204 in series in the longitudinal direction . The module group is high on the left and low on the right.

[0043] see Figure 3-5 The grate cooler module shown includes a bottom frame 1, three rows of trays 105, 106, 107 are arranged on the upper part of the bottom frame, each row of trays extends along the longitudinal direction, and a row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com