Perpendicularity and location degree gauge of end face size of air exhaust pipe

A technology for verticality and exhaust pipes, which is applied in the field of verticality and position inspection tools for the end face of exhaust pipes, and can solve problems such as missing detection pins, inaccurate detection, and wear and tear of detection pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

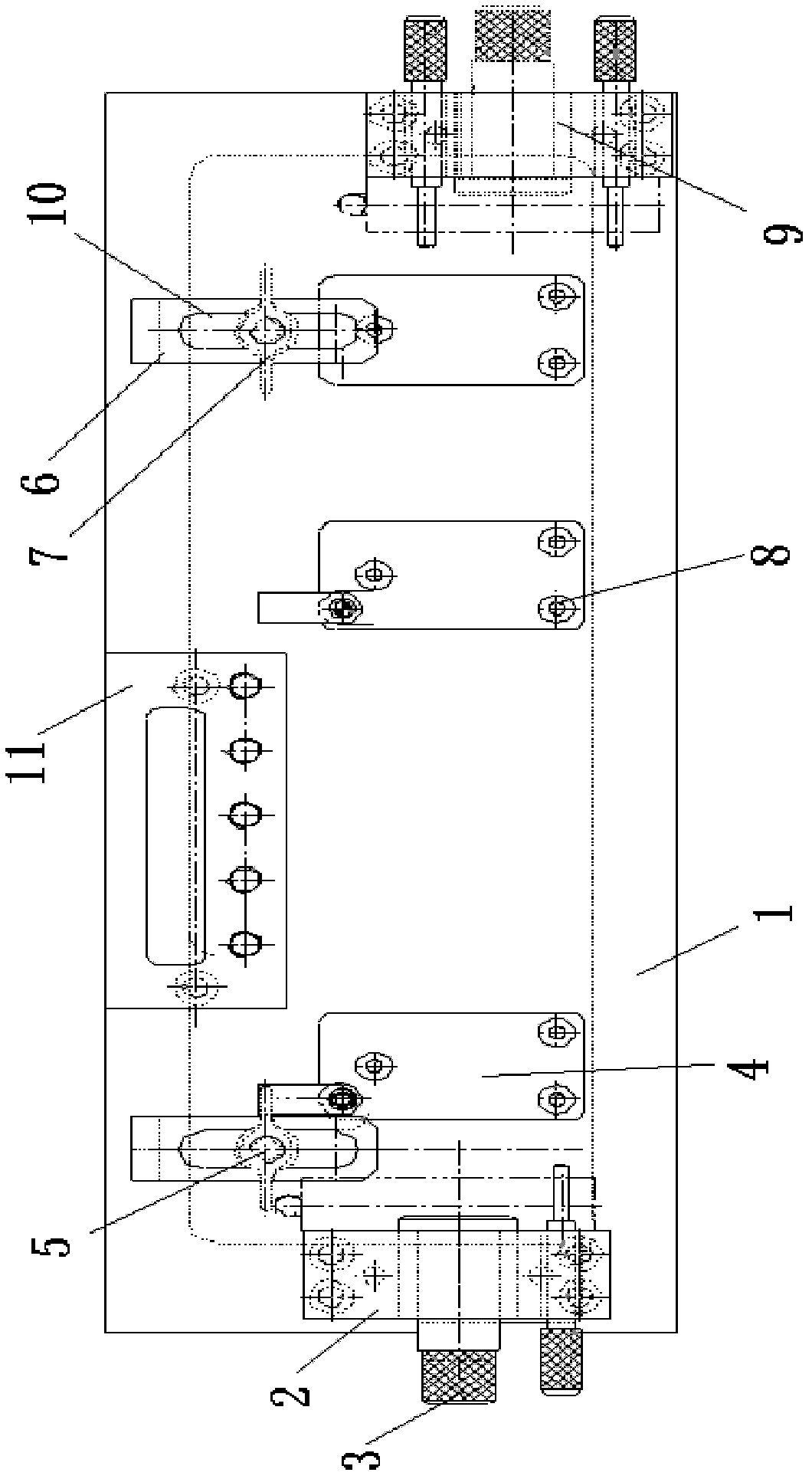

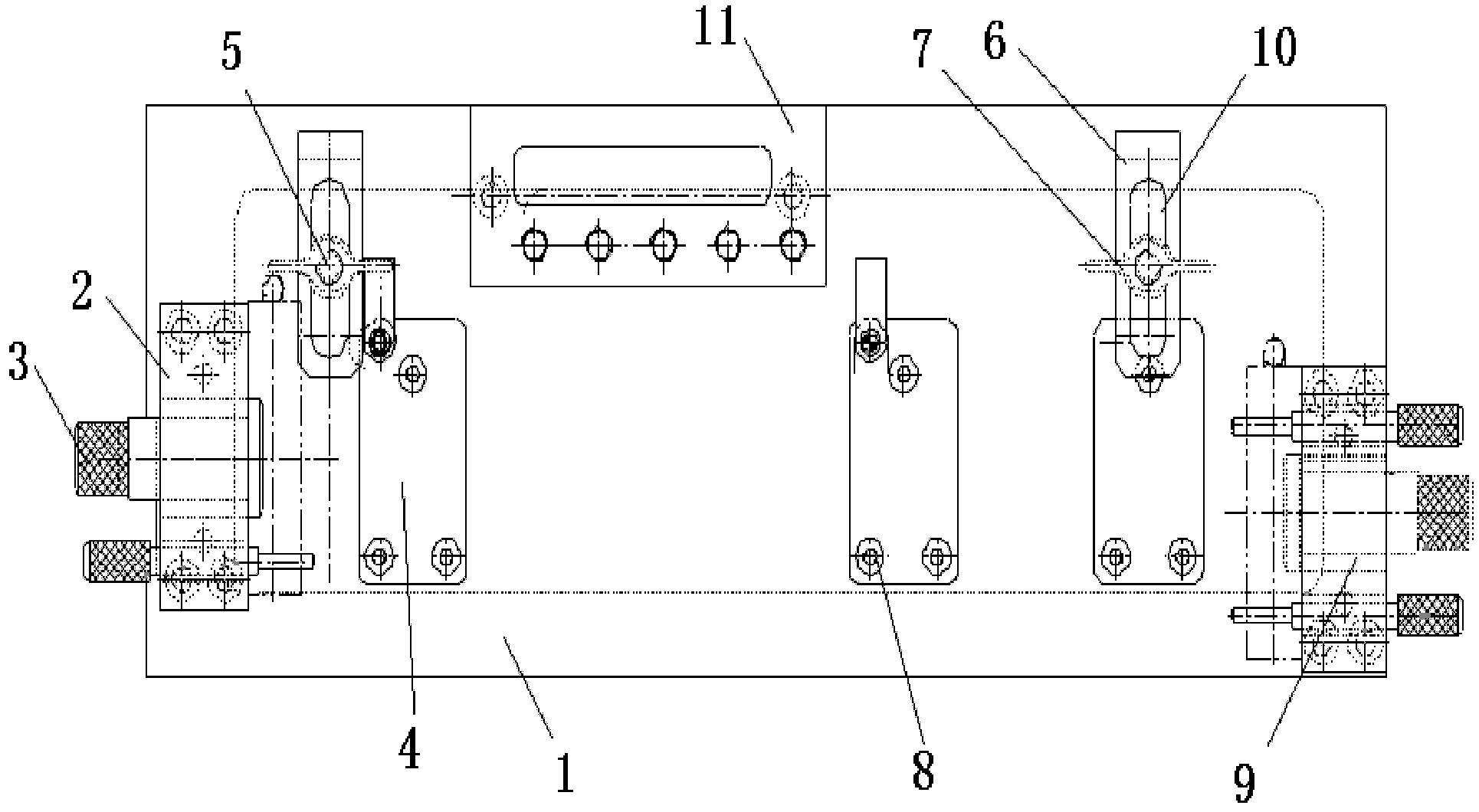

[0012] Referring to the accompanying drawings, a checker for the verticality and position of the end surface of an exhaust pipe includes a checker 1, the left and right ends of the checker 1 are respectively provided with brackets 2, and the left and right brackets 2 are pierced with detection pins 3. A plurality of pads 4 are provided on the inspection body 1 between the left and right brackets 2, and left and right double-ended studs 5 are arranged on one side of the inspection body 1 between the left and right brackets 2. A spring is sheathed on the double-ended stud 5 , a pressing plate 6 is arranged on the upper end of the spring, and a disc nut 7 is arranged above the pressing plate 6 .

[0013] The spacer 4 is provided with a plurality of hexagon socket cap screws 8 .

[0014] A bushing 9 is provided between the detection pin 3 and the bracket 2 .

[0015] The central position of the pressing plate 6 is provided with a strip-shaped hole 10 , and the pressing plate 6 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com