Method for detecting reconstituted tobacco thickness in papermaking process by utilizing near infrared spectrums

A near-infrared spectroscopy and tobacco reconstituted technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of poor stability of measurement and reading of samples with rough surfaces, avoid the accuracy of result characterization, save costs, and improve analysis efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for detecting the thickness of reconstituted tobacco leaves by using near-infrared spectroscopy, the steps are as follows:

[0021] ① Collect and prepare 300-500 samples of reconstituted tobacco leaf product series with different papermaking methods, visually inspect the collected samples, and remove samples with obvious protrusions on the surface and holes visible to the human eye, and the remaining samples shall be in accordance with GB / T 16447 "Tobacco and Tobacco Products The temperature, humidity and time requirements of the method stipulated in the "Adjustment and Test Atmospheric Environment" should be adjusted to the collected samples. After adjustment, the thickness should be measured one by one according to the method of GB / T451.3 "Measurement of Paper and Cardboard Thickness", and the thickness can be obtained. Quantitative reference data.

[0022] ②According to the quantitative reference data measured by the standard method, some samples were scre...

Embodiment 2

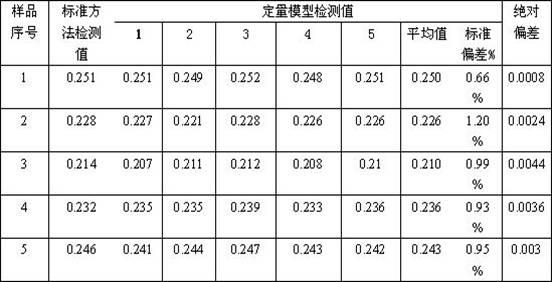

[0038] Collect 5 samples of reconstituted tobacco leaves by the papermaking method to be tested on the production line, call the model established in Example 1 to predict the thickness index, and predict 5 times for each sample, and apply the standard method to measure the thickness of the sample at the same time. The measurement results are shown in Table 3 :

[0039] Table 3 Test results of production samples Test results

[0040]

[0041] It can be seen from Table 3 that when applied in production practice, the standard deviation of the multiple measurement results of the same sample is small, and the absolute deviation between the model prediction results and the standard method detection values is less than 0.005. Visible near-infrared spectroscopy is feasible for the thickness detection of reconstituted tobacco products of.

[0042] All kinds of papermaking reconstituted tobacco leaf samples in each step of the present invention can be obtained from enterprises p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com