Drilling parameter detector

A detector and parameter technology, applied in the field of drilling rigs, can solve problems such as the difficulty in measuring the depth of drilling holes and the inability to accurately measure the opening angle in the three-dimensional space of drilling holes, etc., and achieve the effect of compact structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

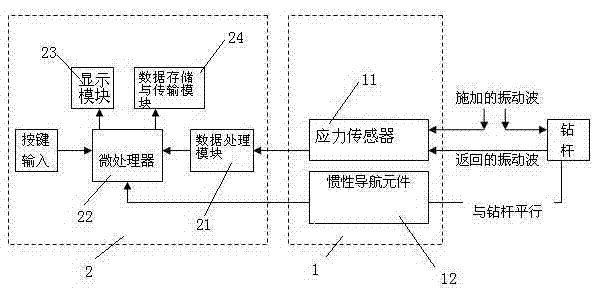

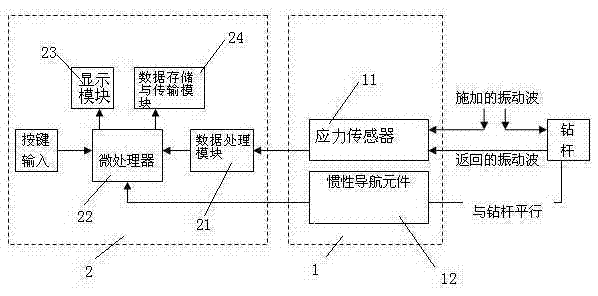

[0018] Such as figure 1 As shown, the drilling parameter detector includes a host device 2 and a sensing head device 1; wherein,

[0019] The host device 2 includes a data processing module 21, a microprocessor 22, and a display module 23. The sensing head device 1 includes a stress sensor 11 and an inertial navigation element 12. Vibration waves are applied to the drill pipe in the borehole at the hole through the impact device. , the vibration wave will be transmitted in the drill pipe, and return an attenuated vibration wave, the stress sensor 11 is used to capture the vibration waveform of the vibration wave propagating in the drill pipe, and output the captured d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com