Mine-filling pipage test method and special equipment

A technology of pipeline transportation and special equipment, which is applied in the direction of fluid dynamics test, machine/structural component test, flow characteristics, etc. It can solve the problems of manpower consumption, excessive material resources, long time, etc., and achieve low cost and easy operation , easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment, the present invention will be further described.

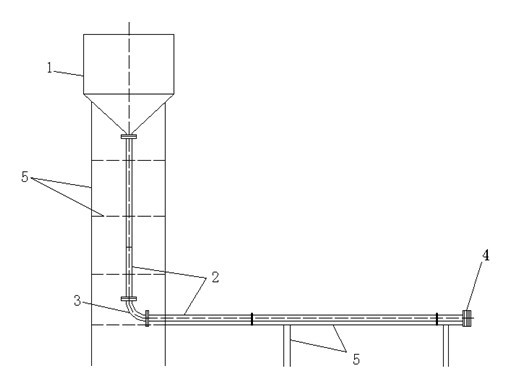

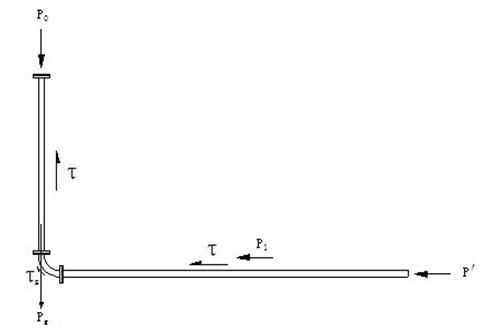

[0015] A special equipment for filling mine pipeline transportation test, including hopper 1, conveying pipe 2, detachable pipe plug 4, support 5, the conveying pipe is arranged on the support, it is an L-shaped pipeline structure composed of horizontal pipeline and vertical pipeline, and the hopper is vertical Arrangement, connected with one end of the vertical pipe of the conveying pipe, and the other end of the horizontal pipe of the conveying pipe is provided with a detachable pipe plug. Said conveying pipe is an L-shaped pipeline structure, which is composed of a horizontal pipeline, a vertical pipeline and a 90° elbow 3, and the horizontal pipeline and the vertical pipeline are connected together by a 90° elbow to form an L-shaped pipeline structure. There are also related auxiliary equipment and measuring tools, including receiving tanks, measuring cylinders, buckets, stopwatches, box rulers,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com