Method for monitoring compaction of concrete-filled steel tube structure based on piezoelectric intelligent aggregate

A technology of piezoelectric intelligent aggregate and steel pipe concrete, which is applied in the direction of material analysis, measuring devices, and analysis materials through electromagnetic means, can solve the problems of expensive ultrasonic testing equipment, and achieve breakthroughs in damage assessment bottlenecks, rapid monitoring, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the accompanying drawings.

[0053] Such as Figure 4 The way shown, in a 300×300×9000mm 3 9 pieces of piezoelectric intelligent aggregates are pre-embedded in the square steel tube concrete column, and the concrete is poured and maintained naturally.

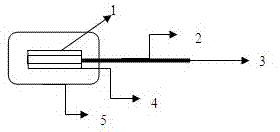

[0054] Such as figure 2 As shown, the piezoelectric smart aggregate includes PZT sheet, silica gel waterproof layer, shielded wire, shielded joint, fine stone concrete or mortar outer cladding.

[0055] The specific operation steps of the monitoring method in the present embodiment are:

[0056] a. First determine the serial number of the piezoelectric intelligent aggregate. In this example, the serial number is from bottom to top, such as Figure 4 shown.

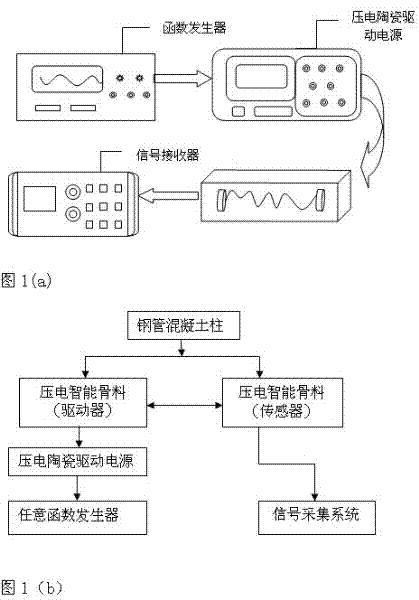

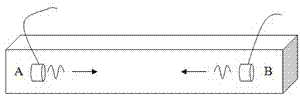

[0057] b. Take 1 and 2 smart aggregates as an example figure 1 (a) and Figure 4 As shown in (d), first the pulse wave is excited by aggregate 1 and received by aggregate 2, and then ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com