Molding method and apparatus of three-dimensional cavity model for true three-dimensional model test

A three-dimensional model and model technology, applied in geophysical surveying, instruments, etc., can solve problems such as the inability to effectively form three-dimensional cavities, and achieve the effects of accurate shape and size, convenient operation, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

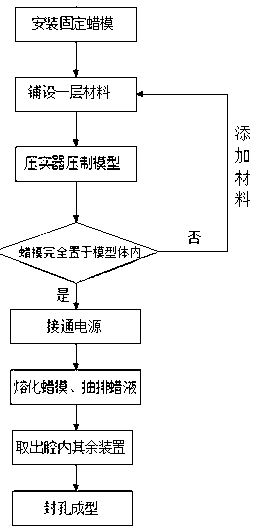

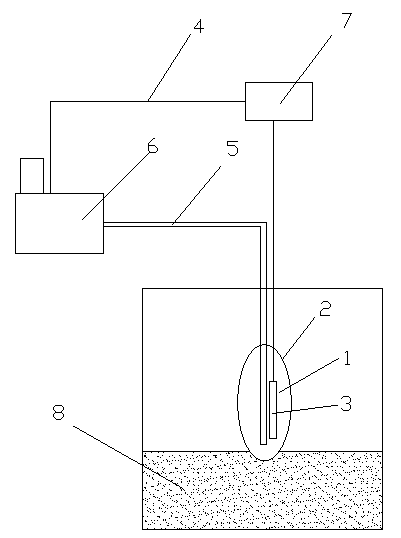

[0035] Such as figure 1 , 2 As shown, a method and equipment for making a three-dimensional cavity model for a real three-dimensional model test.

[0036] Production Method The steps are:

[0037] 1) Make a wax model (wax model) 1 that is consistent with the size of the proposed cavity, and preset heating rods and catheters 5 in its body;

[0038] 2) Wrap the wax model 1 in the milk capsule 2.

[0039] 3) Laying similar materials in the model reaction frame 9 to press the three-dimensional similar material model 8 . When the model body 8 is filled to the bottom of the cavity, the wax model 1 wrapped with milk capsules is placed in the corresponding position of the proposed cavity;

[0040] 4) Lay model-like materials around the wax model 1, continue to press the three-dimensional model 8 until the wax model 1 is completely placed in the entire th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com