Magnetic medium-assisted pipe internal pressure forming method

A magnetic medium and auxiliary tube technology, applied in the field of magnetic medium-assisted internal pressure forming of pipes and internal pressure forming of pipes, can solve problems such as poor force transmission effect, difference, and difficult sealing, and achieve low cost, simple method, and high resilience. Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

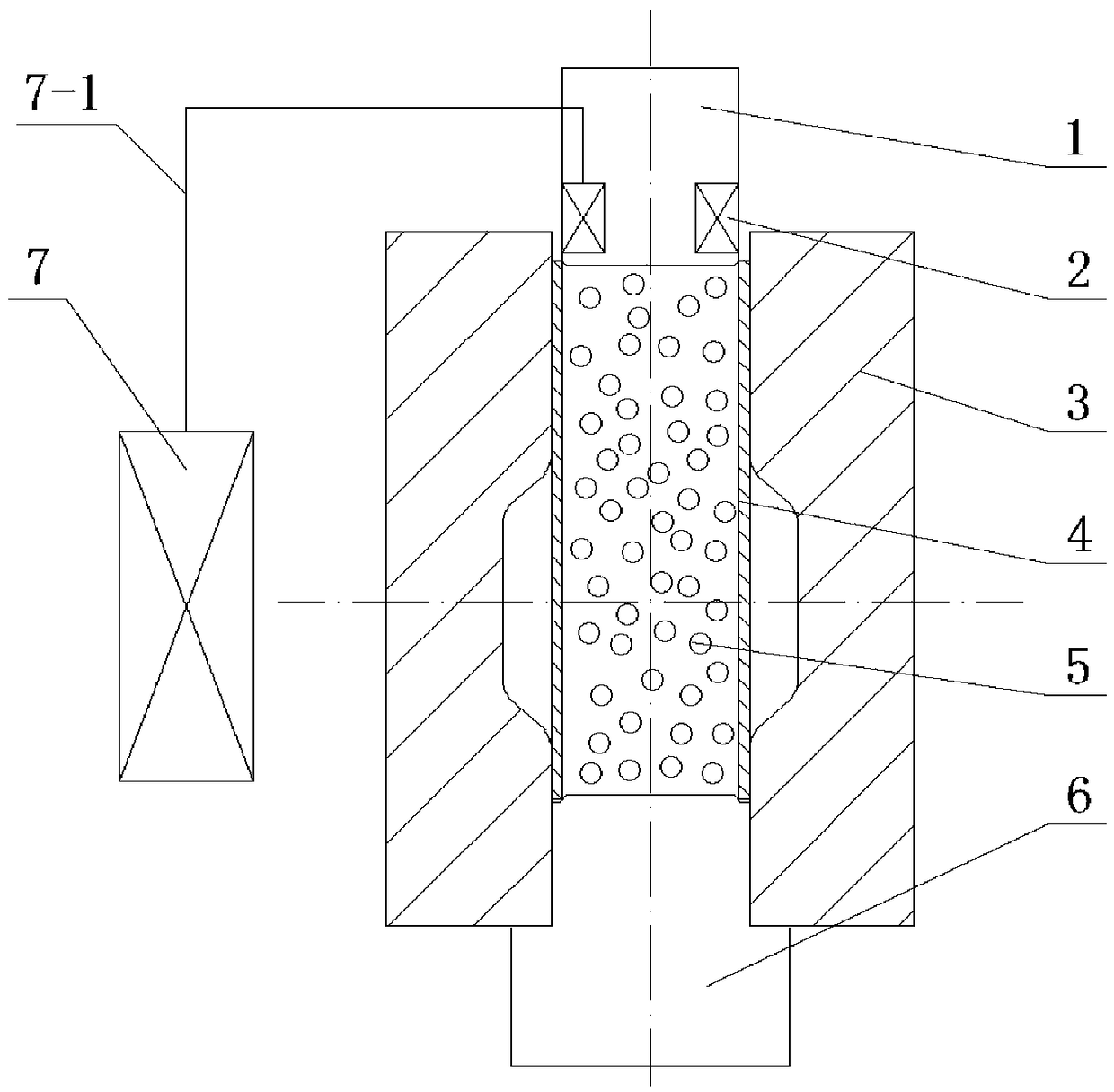

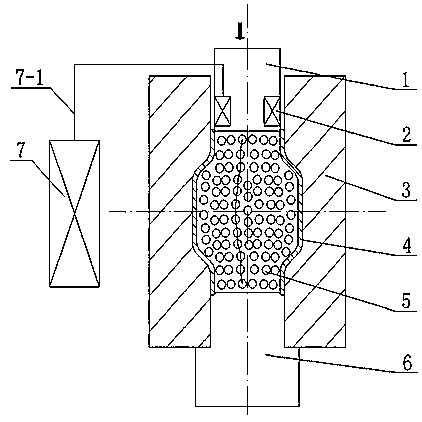

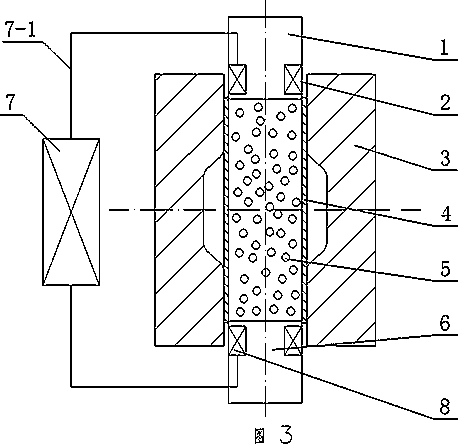

[0026] Specific implementation mode one: combine Figure 1~2 Describe this embodiment, this embodiment includes an upper punch 1, an upper coil 2, a die 3, a tube blank 4, a magnetorheological fluid 5, a lower punch 6, a magnetic control unit 7, and a wire 7-1. Prepare the magnetorheological fluid 5 with the required components in proportion. The magnetorheological fluid is composed of base fluid, magnetizable particles, and stabilizers according to a certain volume fraction, of which the base fluid accounts for 10% to 40%, and the magnetizable particles account for 35%~85%, the stabilizer accounts for 0~10%. The upper punch 1 and the die 3 are arranged facing up and down, the die 3 and the lower punch 6 are arranged facing up and down, and the tube blank 4 is located in the cavity surrounded by the upper punch 1, the die 3 and the lower punch 6, and the cavity The magneto-rheological fluid 5 is contained inside, the upper coil 2 is placed at the end of the upper punch 1, and...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 Describe this embodiment. In this embodiment, the magnetorheological fluid in step 1 is composed of base liquid, magnetizable particles and stabilizer according to a certain volume fraction. Among them, the base liquid accounts for 40%, and the magnetized particles account for 56%, which is stable. agent accounted for 4%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, the magnetorheological fluid in step 1 is composed of base liquid, magnetizable particles and stabilizer according to a certain volume fraction. Among them, the base liquid accounts for 30%, and the magnetized particles account for 65%, which is stable. agent accounted for 5%. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com