Curved surface and vertical surface aluminum plate mounting method

An installation method and curved surface technology, applied in covering/lining, building, building structure, etc., can solve the problems of small error, high precision, low precision, large error, etc., and achieve the effect of eliminating installation error and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

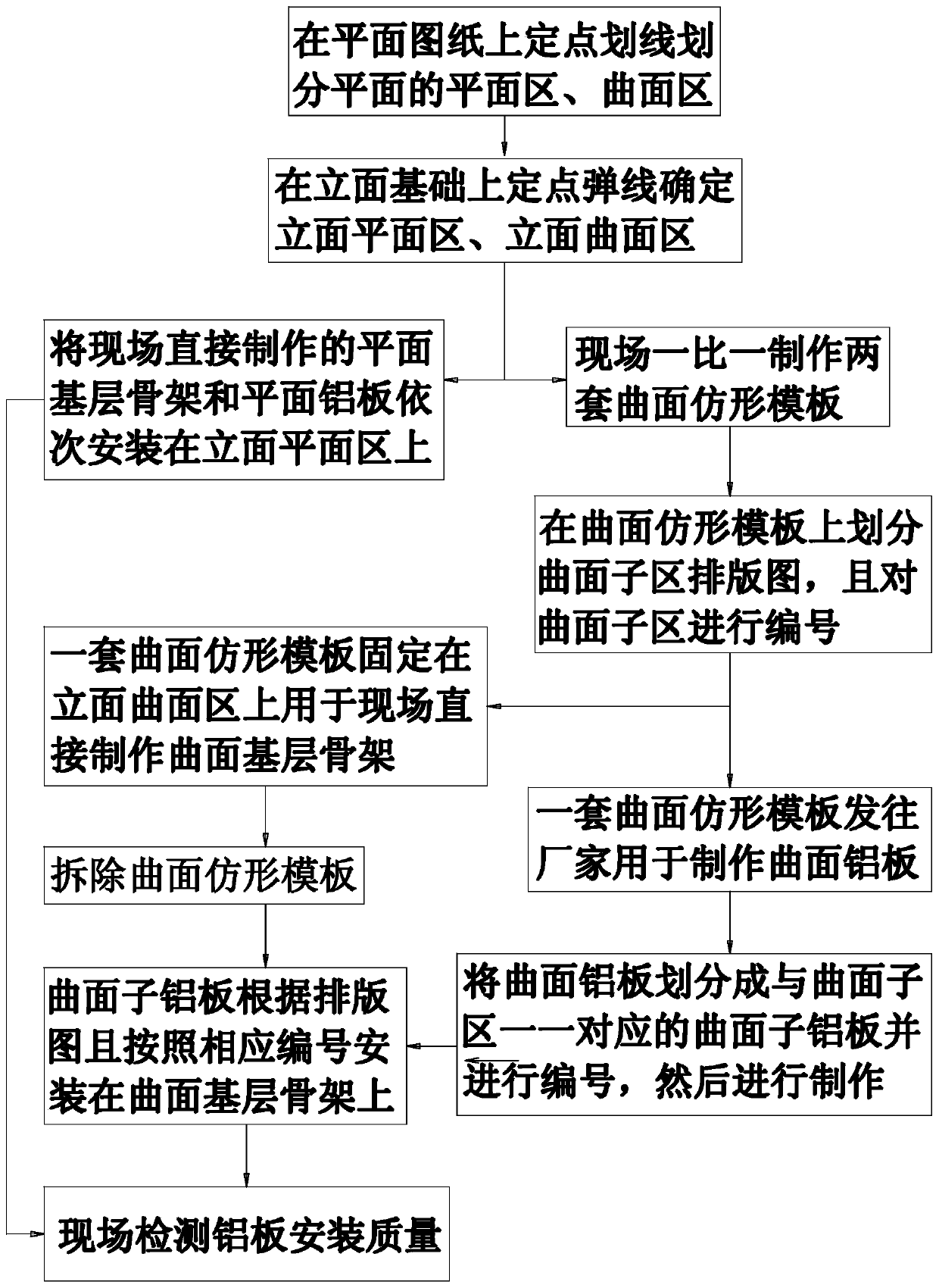

[0015] as attached figure 1 Shown: a method for installing aluminum panels on curved facades, step 1, divide the planar area and curved area of the plane with fixed points and dashed lines on the plan drawing; The plane area and the curved area of the facade; Step 3, install the plane base frame and the plane aluminum plate directly made on site on the plane area of the facade; Step 4, according to the curved area of the facade, make two sets of curved imitation Shaped formwork, a set of curved surface profiling templates is fixed on the curved surface area of the facade for direct production of the curved base frame on site, and another set of curved surface profiling templates is used to make curved aluminum panels, and the finished curved aluminum panels are installed on the curved base frame; Step 5: Remove the curved formwork used to make the on-site ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com