A decorative insulation board and refrigeration equipment using the board

A technology of thermal insulation board and packaging film, which is applied in the field of decorative thermal insulation boards, can solve the problems of reducing the overall thermal insulation performance of VIP boards and affecting the flatness of product planes, and achieve stable and controllable quality, long-term stable thermal conductivity, and improved thermal insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

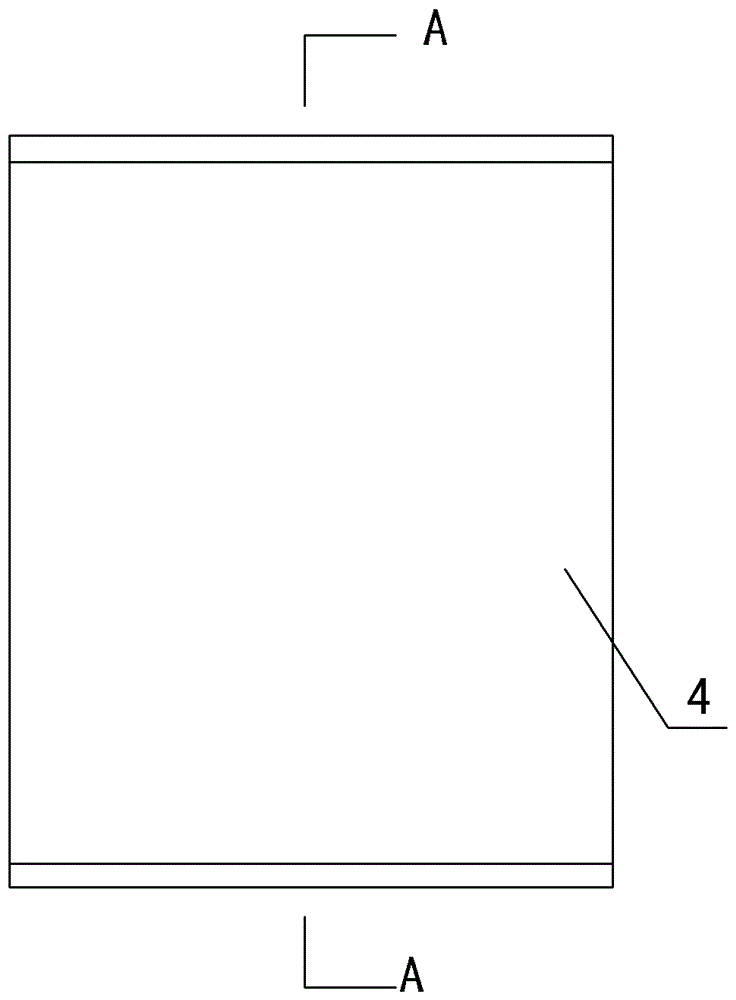

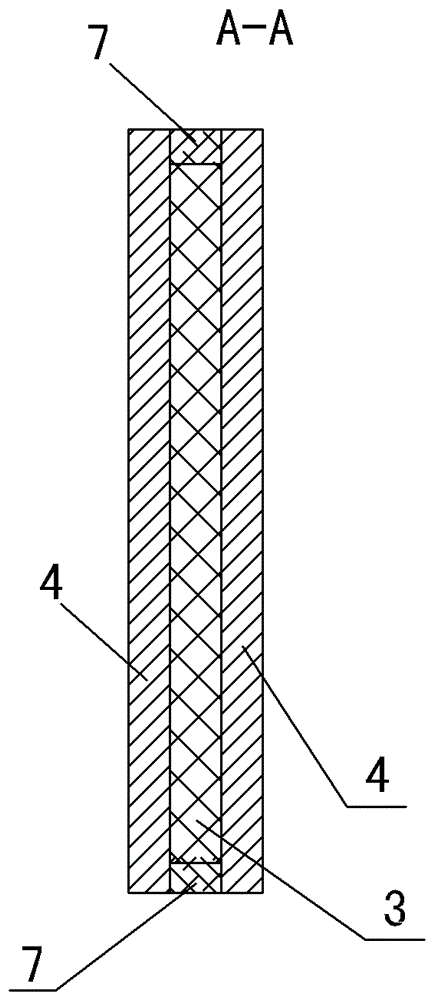

[0078] Such as Figures 1 to 2, The decorative insulation board in this embodiment includes: a VIP board 3 and a cellulose board 4 bonded to both sides or a single side of the VIP board 3 by pressure-sensitive adhesive (ie, acrylic glue) or silica gel. Among them, acrylic adhesive has many advantages such as room temperature curing, convenient operation, high bonding strength, fast positioning, high elasticity, and non-toxic cured product; acrylic adhesive is a one-component, with excellent water resistance, heat resistance, cold resistance, aging resistance , acid and alkali resistance, corrosion resistance, oil resistance and no whitening and other excellent characteristics, suitable for refrigerators, freezers and other oily environments.

[0079] The outer surface of the cellulose board 4 is provided with a decorative layer, and can be carved, painted, and variously decorated.

[0080] The sealing tape or sealing strip 7 around the VIP board, and the sealing tape or seali...

Embodiment 2

[0087] On the basis of Embodiment 1, this embodiment has the following modifications:

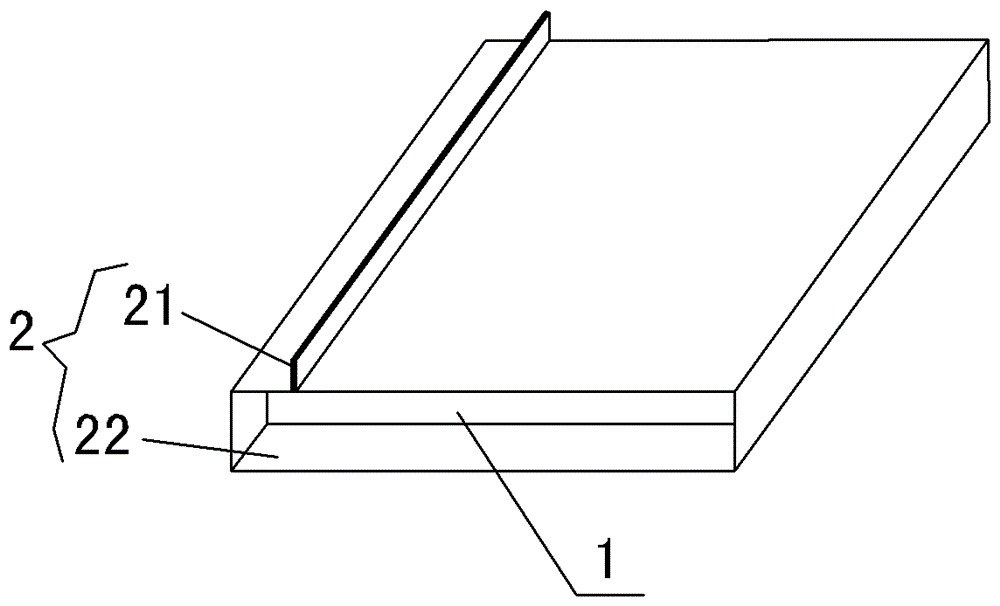

[0088] As shown in Figures 6 to 8, the encapsulation film 2 is two sheets connected end to end, and the corresponding two end to end joints 21 are simultaneously on the upper or lower plane of the core material, or on the core at the same time. on the edge of the core material 1, or on the upper and lower planes of the core material 1 respectively.

Embodiment 3

[0090] The production method of the VIP plate of above-mentioned embodiment 1 or 2, comprises the steps:

[0091] A. After covering the upper and lower planes and the left and right sides of the core material with at least one packaging film, the head and tail are hot-melt connected, and the head and tail connection is not on the left and right sides of the core material;

[0092] B. The extensions of the packaging film that extend out of the front and rear sides of the core material are folded symmetrically toward the center of the inner side along the four edges of the front and rear sides of the core material; during the folding process, the The part of the opening of the extension part adjacent to the short side is M-shaped;

[0093] C. After being folded over, the parts of the extension part adjacent to the front and rear sides of the core material are respectively closely attached to the front and rear sides of the core material;

[0094] D. Hot-melt seal the opening of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com