Plug prevention device for dust removing equipment of dusty gas in power plant and preparation method thereof

A technology for gas dust removal and power plants, which is applied in the field of air purification, dust removal and anti-blocking devices in power plants and its preparation, which can solve the problems of easy damage of filter bags, achieve the effects of improving dust removal efficiency, simple production, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

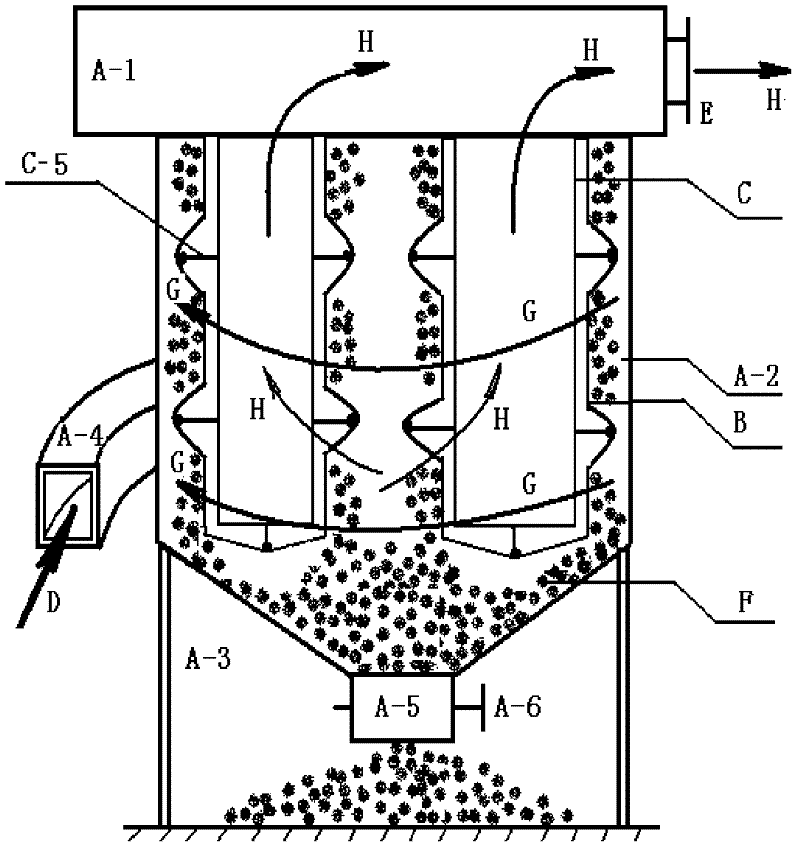

Method used

Image

Examples

Embodiment 1

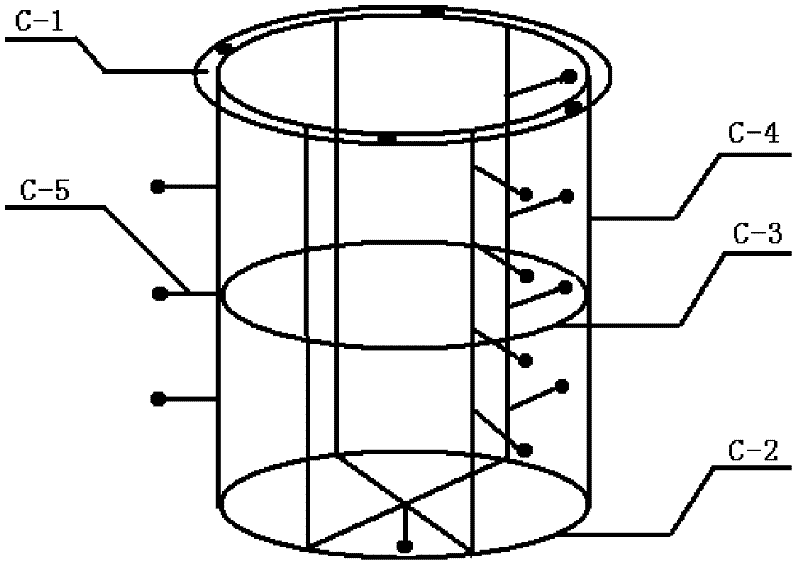

[0027] The support body C-5 in this embodiment is an independent body. Shaped frame C, such as figure 2 , image 3 As shown, it consists of the upper hoop C-1, the lower net ring C-2, the pole C-4, the fixing ring C-3 in the pole and the support body C-5. Wherein, the support body C-5 is formed by welding the support body rod C-5-a and the support body cap C-5-b, and the end surface of the support body cap C-5-b is an arc surface. The upper hoop C-1 is composed of the inner ring of the upper hoop and the outer ring of the upper hoop welded with the same center. The lower net ring C-2 is welded with two rod-shaped stainless steels in the ring to form a net ring. The connection method is to use 6 vertical rods C-4, which are evenly arranged in a barrel shape, and are connected with the inner ring of the upper hoop, the fixed ring C-3 of the vertical rod and the lower net ring C-2. In addition, 8 supports are used Body C-5 is vertically outwardly dispersed and welded on the ...

Embodiment 2

[0031] The support body C-5 in this embodiment is an independent body. For the special-shaped frame C, 12 vertical poles C-4 and 40 supports C-5 are selected. The supporting body C-5 is dispersedly welded on the vertical pole C-4 and the neutral pole fixing ring C-3. Component specifications: The height of special-shaped frame C is 2000mm. Except for the support body cap C-5-b, which is a ball with a diameter of 15mm, the rest of the components are rod-shaped stainless steel with a diameter of 8mm; among them, the inner ring of the upper hoop, the lower net ring C-2 and the middle fixing ring C-3 of the vertical rod The diameters are all 1000mm; the lengths of the vertical poles C-4 are all 2000mm; the lengths of the support poles C-5-a are 100mm. Others are with embodiment 1.

Embodiment 3

[0033] Support C-5 is not independent. This scheme saves the welding process of making the support body C-5 and its connection with other parts; that is, the rod body material is used, and according to the specification and shape of the support body C-5, it is respectively connected with the vertical rod C-4 and the middle fixing ring of the vertical rod The shape of C-3 or the lower end mesh ring C-2 is bent together to form an integral part, so that the vertical rod C-4, the middle fixed ring C-3 of the vertical rod or the lower end mesh ring C-2 are respectively formed with The convex upright rod of the support body C-5, the fixed ring in the convex upright rod or the net ring at the lower end of the convex shape. The length of the convex vertical rod, the diameters of the fixed ring in the convex vertical rod and the net ring at the lower end of the convex shape are all constant. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com