Mesh anti-blocking method for glass fiber net cloth for reinforcing sand wheel during preimmersion

A technology of glass fiber and mesh, which is applied in the field of mesh anti-blocking of glass fiber mesh cloth, which can solve the problems of increasing equipment, stable influence of working environment, long-term energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Take a square meter with a weight of 120g and a mesh number of 10 mesh (10 meshes per inch) as an example:

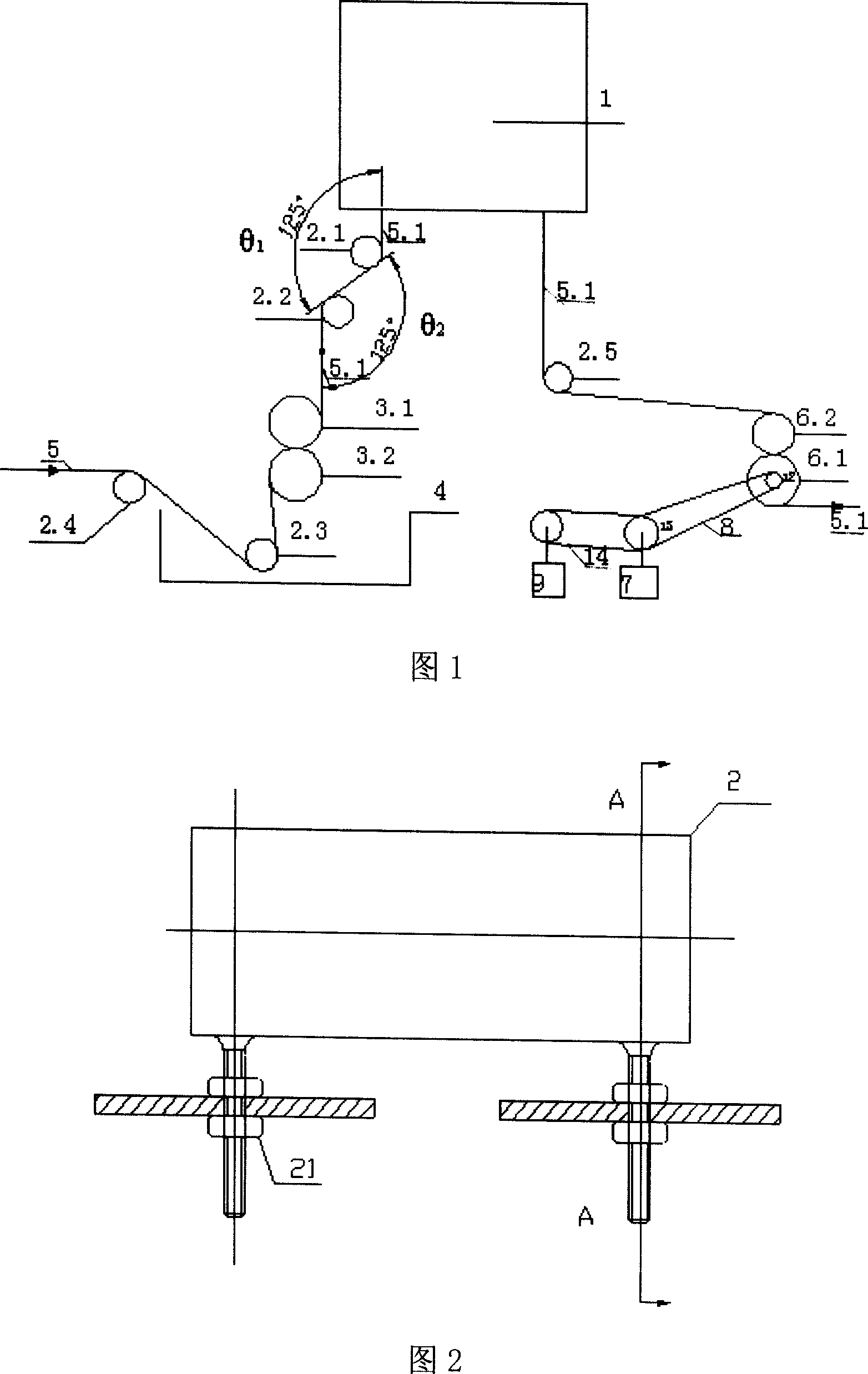

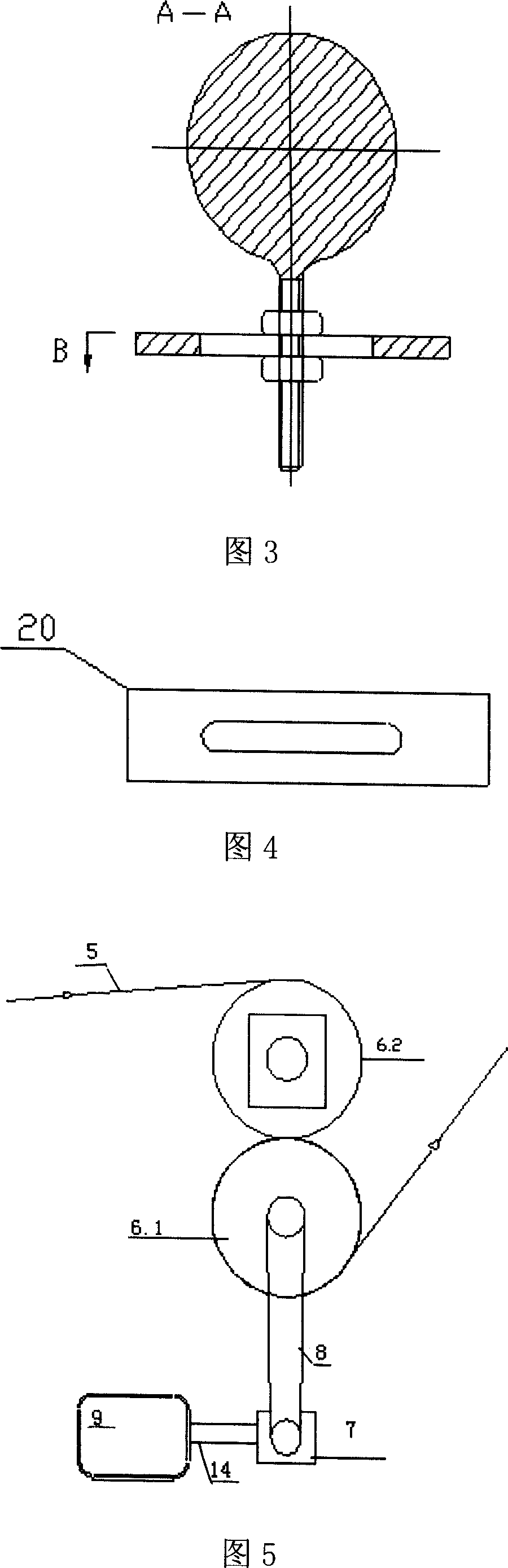

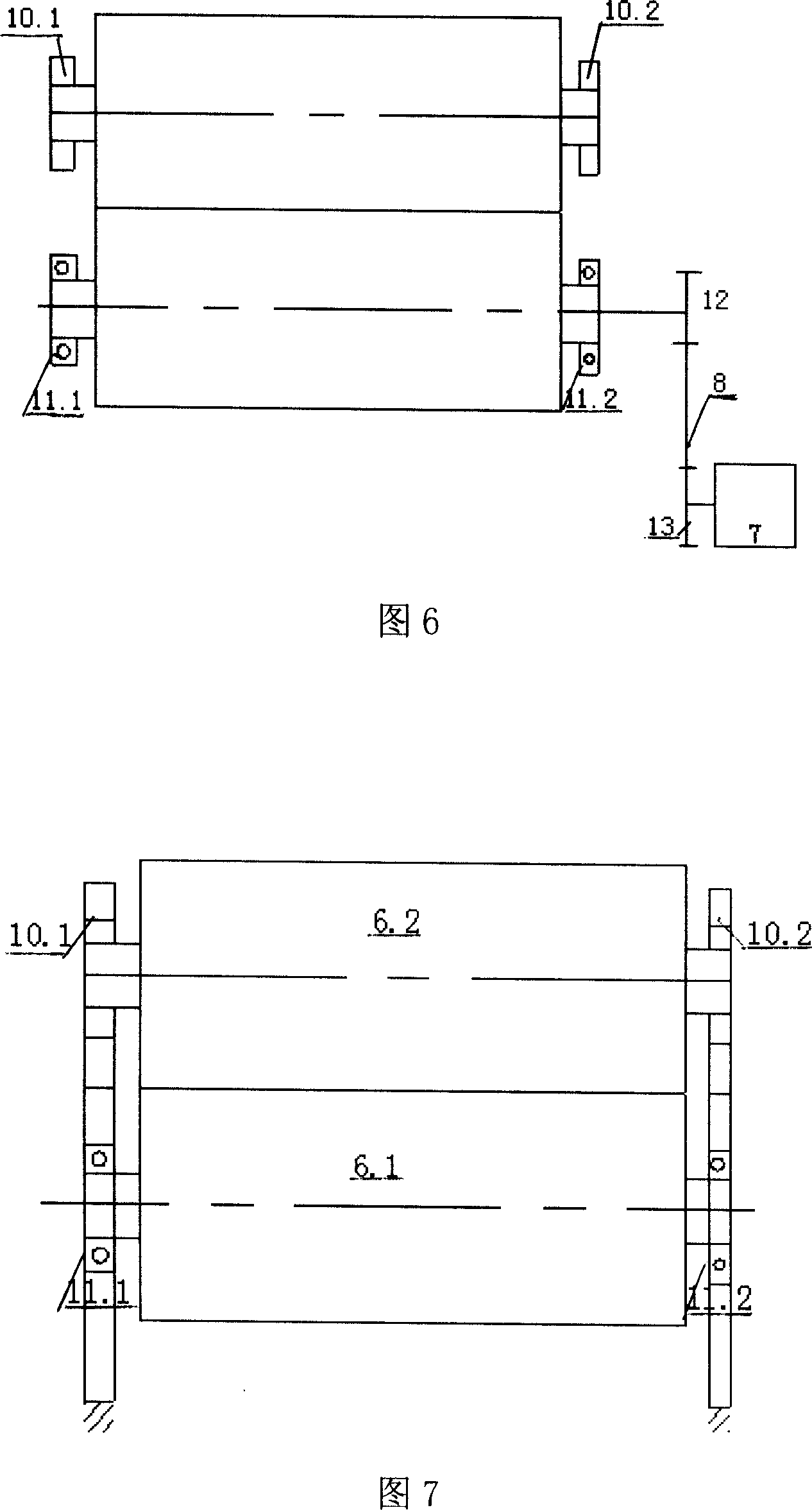

[0033] As shown in Figure 5, when the speed regulating motor 9 is given a constant output speed of 800 rpm, the speed regulating motor 9 is decelerated by the reducer 7, and the reduction motor drives the traction roller 6.1 through the sprockets 12 and 13, so that the traction roller outputs a constant speed , the thorny fur is wound on the traction roller, and the thorny fur gives the mesh prepreg 5 wound on it a constant line speed by static friction. The prepreg passes through the individual equipment elements at a constant speed under the constant pull of the pull rollers. As shown in Figure 1, fix the angle θ of the cloth guide roller 1 , θ 2 The size adjustment is 125°. When the glass fiber mesh 5 passes through the rubber rollers, the rubber rollers 3.1 and 3.2 extrude the resin with a certain viscosity into a very thin resin film and attach it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com