Process for precisely forming inner ferrule blank and outer ferrule blank of bearing

A technology of precision forming and inner ferrule, used in metal extrusion dies and other directions, can solve the problems of long processing time, cumbersome process flow, high manufacturing cost, and achieve high production efficiency, simple and reliable process flow, and high material utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

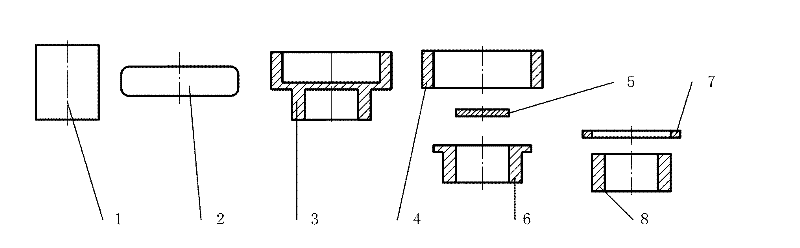

[0023] refer to figure 1 , a precision forming process for bearing inner and outer ring blanks, comprising the following steps:

[0024] The first step is to obtain a cylindrical blank 1 by means of precision blanking, heat it to 900°C for a period of time to austenitize it, and then pre-cool it to 780°C and perform an upsetting on a 5000kN hydraulic press to obtain an upset piece 2,

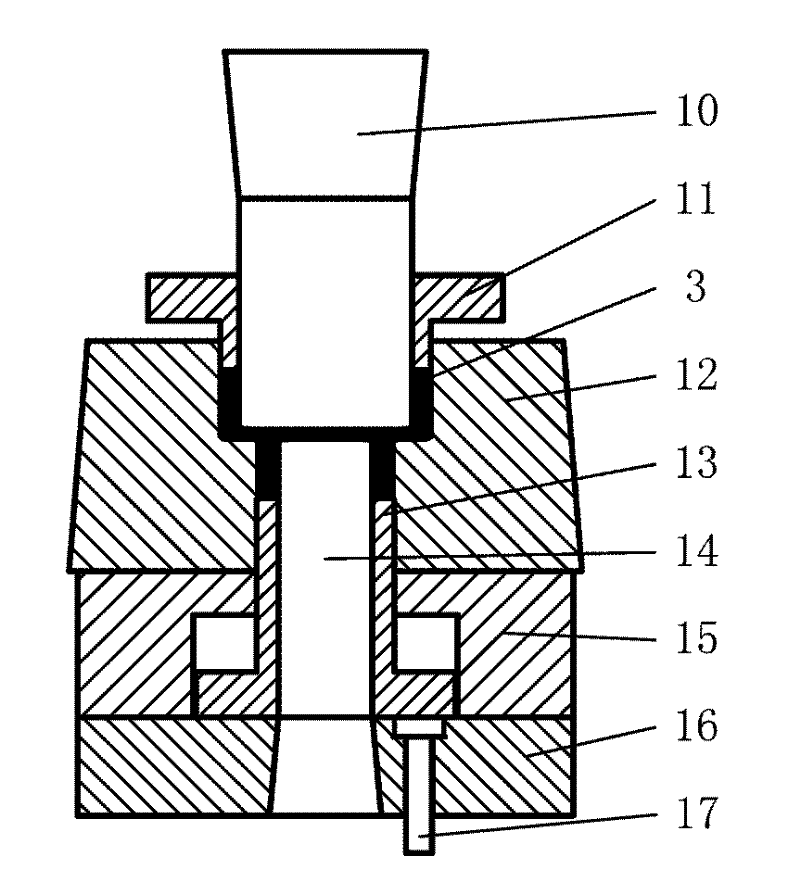

[0025] In the second step, the upsetting piece 2 is transferred to the compound warm extrusion die for compound warm extrusion, and the one-step compound warm extrusion obtains the intermediate extrusion 3 containing the outer ring blank and the inner ring blank, and the termination deformation temperature is Above 720°C,

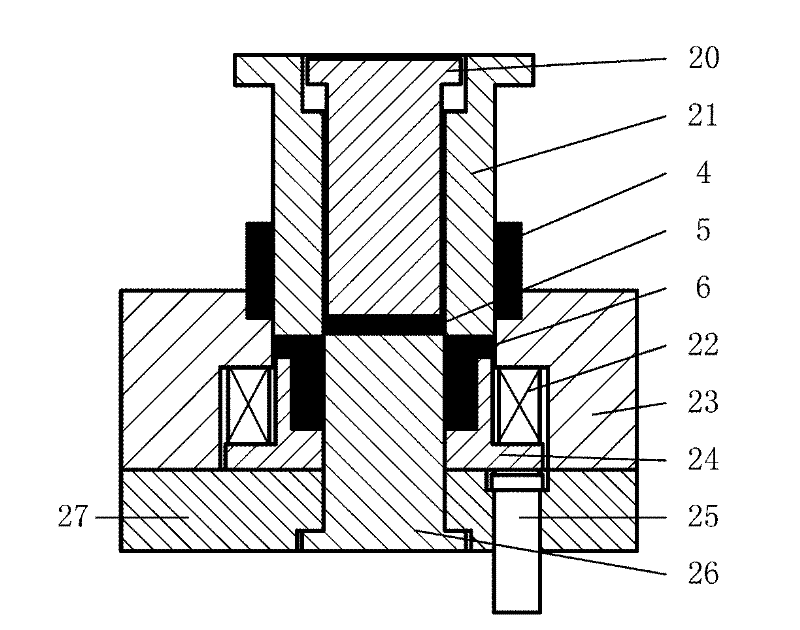

[0026] In the third step, the intermediate extrusion 3 is air-cooled to room temperature, and then the intermediate extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com