Swingable deflection deformation compensation device for ram

A flexural deformation and compensation device technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of flexural deformation compensation, increase the axial movement error of the main shaft, etc., and achieve a good compensation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

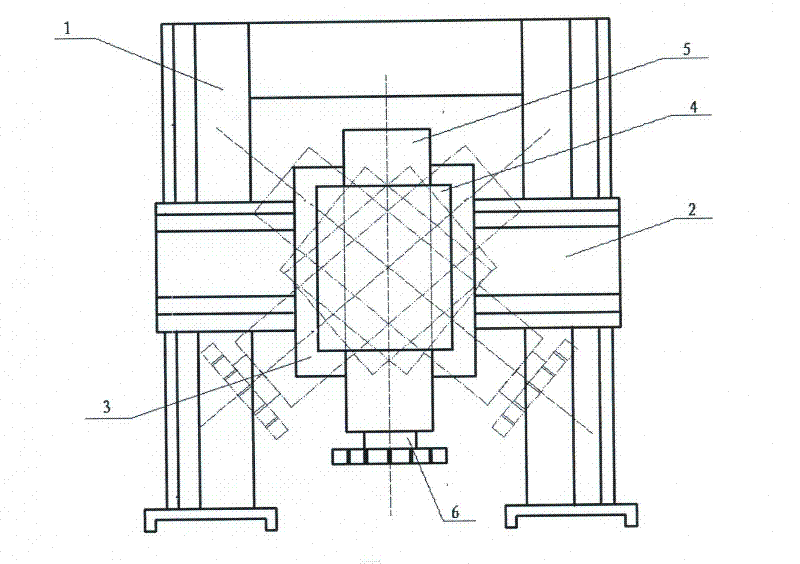

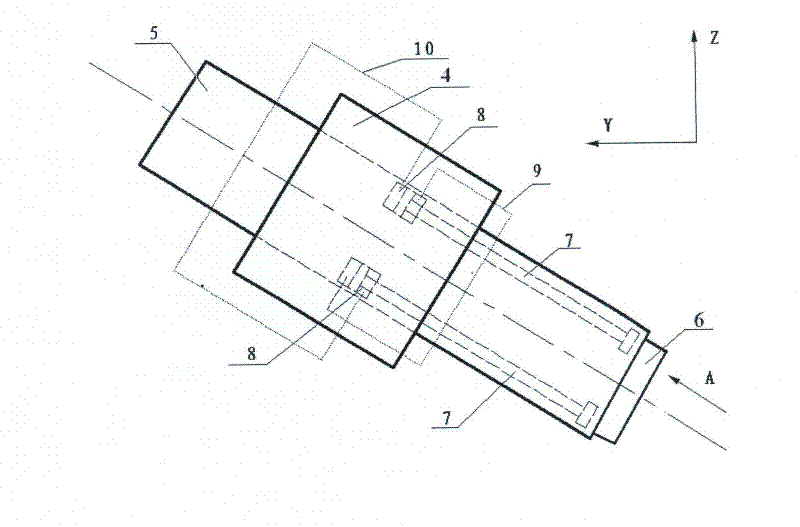

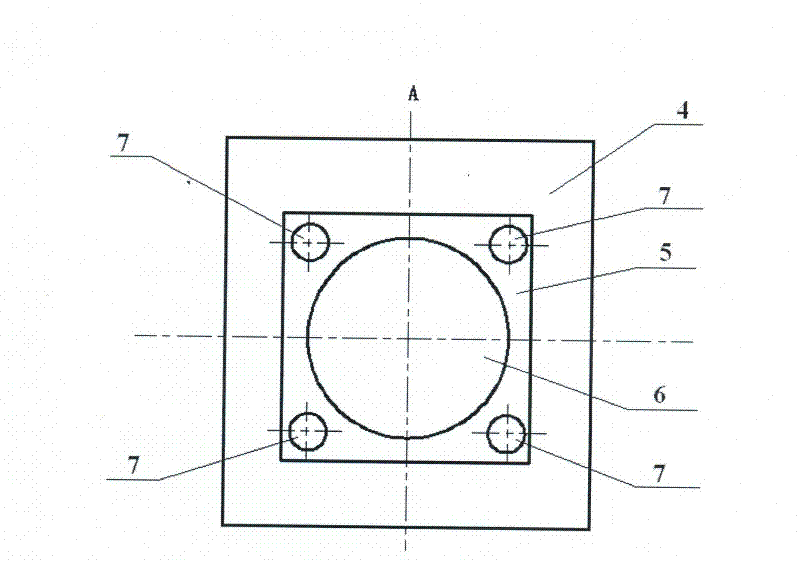

[0013] exist figure 1 In the schematic diagram of the installation position and movement of a swingable ram deflection compensation device shown, the gantry 1 is a gantry-type frame structure composed of left and right columns and connecting beams, and the beam 2 is installed on the left and right columns of the gantry. The crate 3 is installed on the beam, which is driven and positioned by the screw nut pair and the guide rail pair, and is tightly fixed by the pressure plate and the beam. The ram turntable 4 is installed on the slide crate and connected by bearings. The ram 5 Installed on the above-mentioned ram turntable, the main shaft 6 is installed inside the ram. Such as figure 2 , 3 The four same force application rods 7 shown are divided into upper and lower groups, which are respectively installed on the upper side and the lower side of the ram. One group is a pull rod, and the other group is a push rod. The four force rods are arranged along the main axis of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com