Three-finger capture positioning mechanism

A positioning mechanism and single-finger technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of small capture range and weak correction ability, and achieve the effect of simple and reliable structure, strong guiding ability, and large capture range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

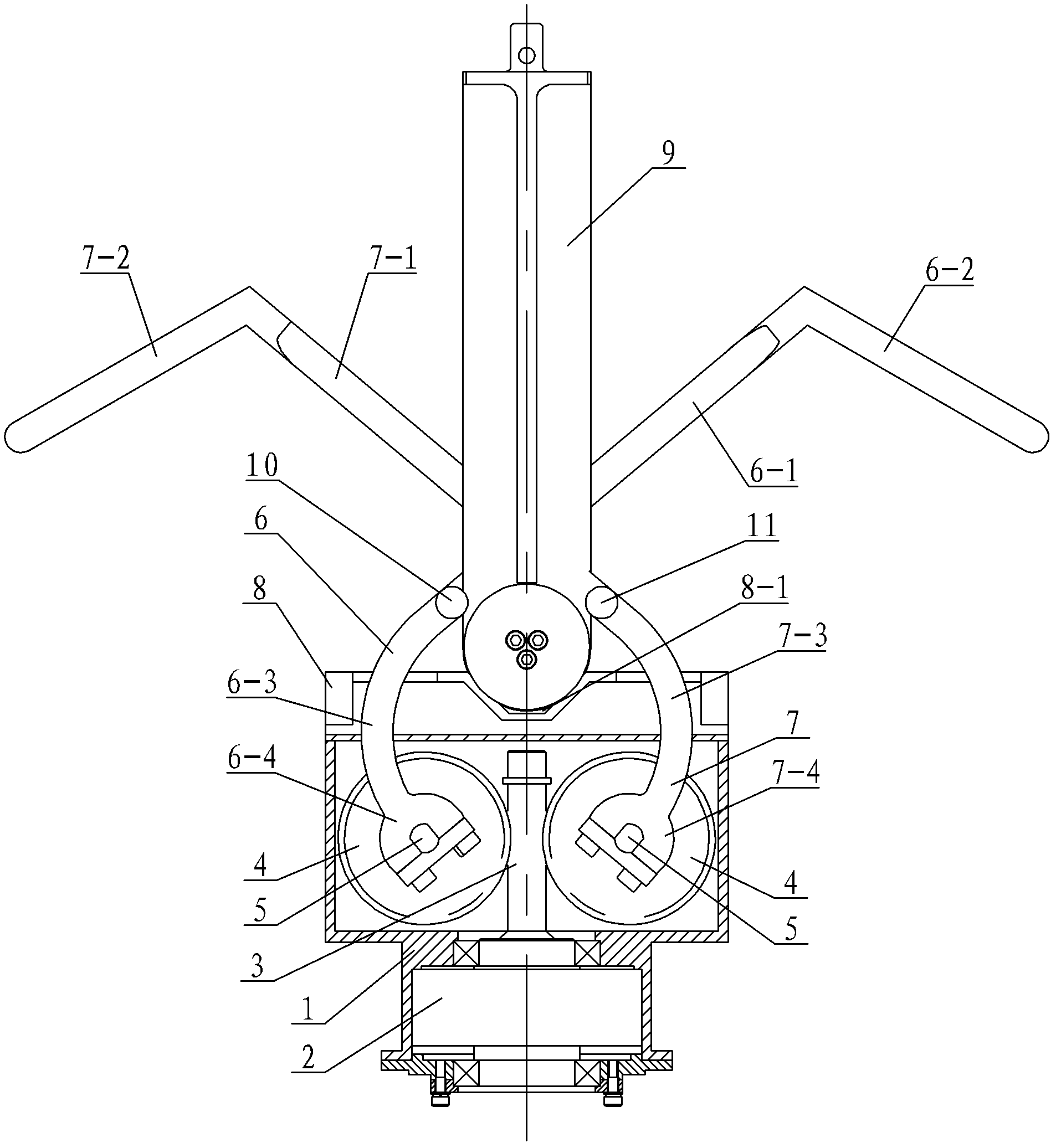

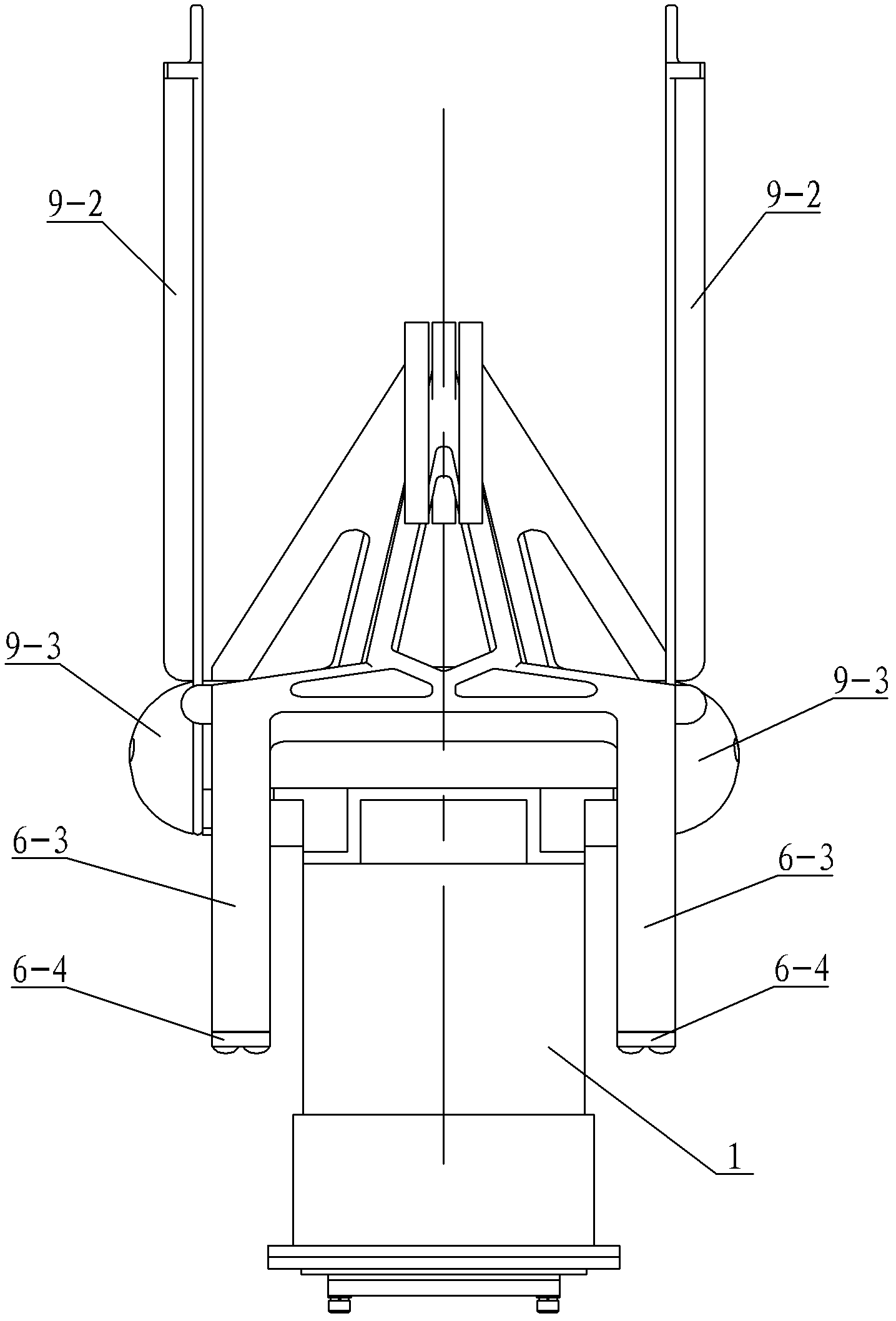

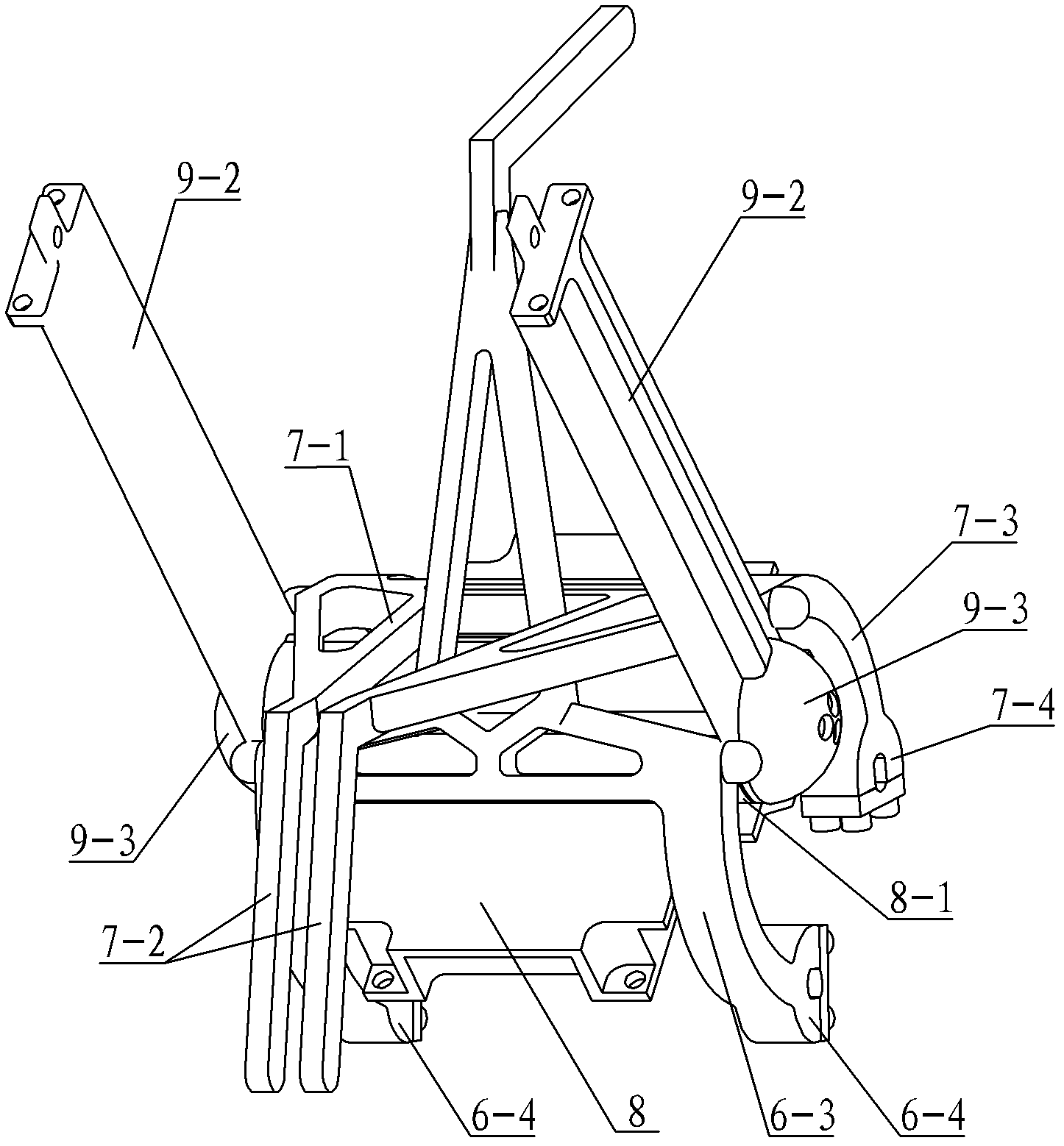

[0007] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, this embodiment includes housing 1, motor 2, worm shaft 3, two worm wheels 4, two worm shafts 5, single finger 6, double fingers 7, fixed plate 8 and capture interface device 9, worm shaft 3 is installed in the housing 1 through bearings, the input end of the worm shaft 3 is connected with the output shaft of the motor 2, two worm gears 4 are symmetrically arranged on both sides of the worm shaft 3, and both worm gears 4 are connected to the The teeth mesh, the worm gear 4 is installed on the worm gear shaft 5, the two ends of the worm gear shaft 5 are installed on the housing 1 through bearings, the single finger 6 is composed of a single finger connecting arm 6-1, a single finger capture head 6-2, two single finger The finger curved arm 6-3 is composed of two single-finger connectors 6-4, the single-finger capture head 6-2 is arranged on the upper end of the single-finger connect...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with Figure 5 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that it also adds a single-fingered positioning post 10 and a double-fingered positioning post 11, the single-fingered positioning post 10 is arranged in parallel with the V-shaped groove 8-1, and the single-fingered positioning The positioning post 10 is installed on the single-finger connecting arm 6-1, the two-finger positioning post 11 is arranged parallel to the V-shaped groove 8-1, and the two-finger positioning post 11 is installed on the two-finger connecting arm 7-1. The handle 9-1 is compressed by the single-finger positioning post 10 and the double-finger positioning post 11. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with Figure 5 To describe this embodiment, the double-fingered positioning post 11 and the single-fingered positioning post 10 of this embodiment are arranged symmetrically with respect to the central line P-P of the V-shaped groove 8-1. Other components and connections are the same as those in the second embodiment.

[0010] The working principle of the present invention: when in use, the housing 1 is installed on the end effector of the robot, and the two brackets 9-2 on the capture interface device 9 are connected with the capture target; the motor 2 drives the worm shaft 3 to rotate, and the two worm gears 4 rotates thereupon, and two worm gears 4 drive single-finger connector 6-4 and double-finger connector 7-4 to rotate respectively by worm gear shaft 5 thereon, and single-finger capture head 6-2 and two double-finger capture head 7 -2 Envelope the handle 9-1 on the capture interface device 9 back, guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com