Step-by-step punching system

A technology of step count and step distance, which is applied in the field of step-by-step punching system, can solve the problems of affecting the precision of punching machine, complex mold structure, high development and manufacturing costs, etc., to avoid the decrease of precision, simplify the mold structure, and save the mold The effect of development and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

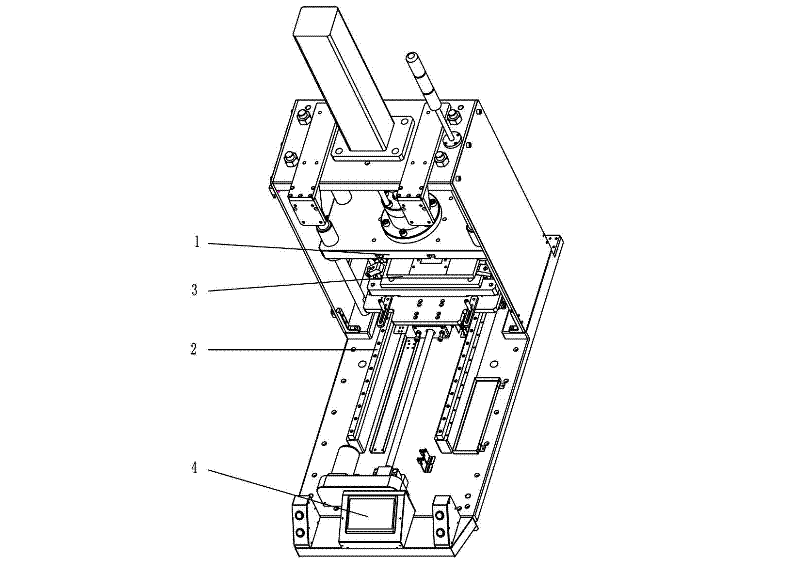

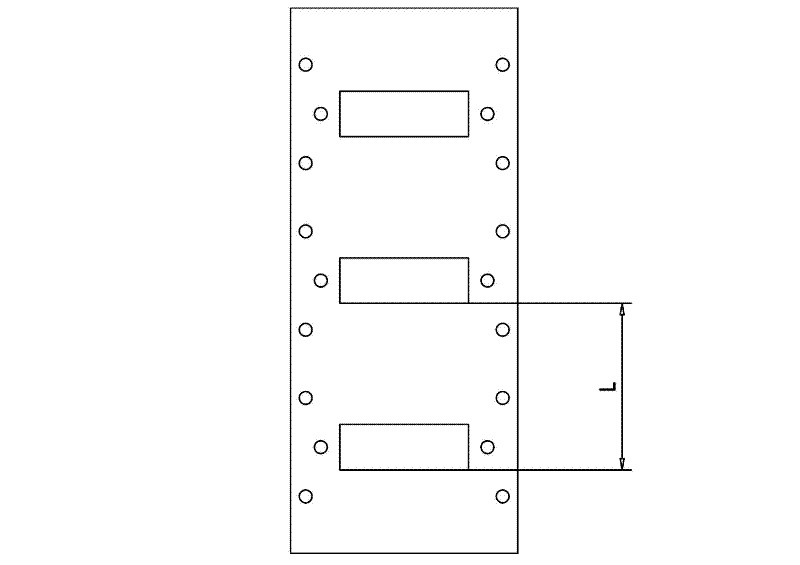

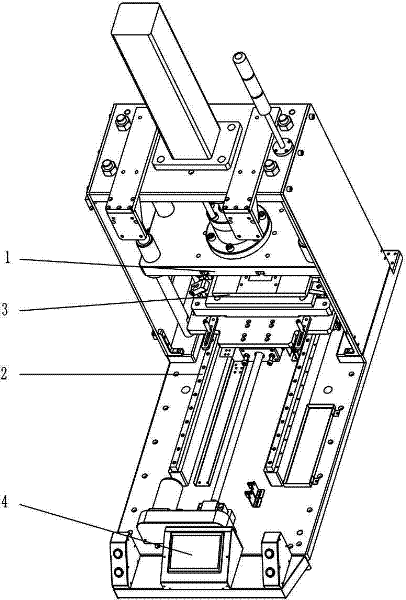

[0016] refer to Figure 1 ~ Figure 2 , a step-by-step punching system, comprising an upper die 1 and its driving device and a lower die 3 installed on the guide rail 2 and its driving device, the upper die driving device and the lower die driving device are connected to an electronic control module; According to the punching requirements of the workpiece to be punched, set the corresponding number of steps and step distance for the electronic control module; figure 2 As shown, the punched workpiece has three identical features, that is, a rectangular frame with three round holes on each side, so the number of steps is 3, and the distance between the same features is L, so the step distance is L. The whole process of punching includes the following steps:

[0017] (1) Unwinding stage: place the workpiece to be punched on the lower die 3;

[0018] (2) Feeding stage: under the control of the electronic control module, the driving device of the lower mold makes the lower mold 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com