Compression roller with compression roller curve matched with steel ring compression face and method for compressing steel ring wrapping fabric

A technology of steel rims and pressure rollers, which is applied in the field of tire manufacturing, can solve the problems of steel rims with many bubbles, achieve the effects of increasing the contact surface, improving quality, and solving the problem of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention adopts a newly designed curve of the pressure roller of the steel ring, so that the curve of the pressure roller and the pressing surface of the steel ring coincides, so that the pressure roller can effectively compress and compact the cloth of the steel ring, eliminate air bubbles inside the steel ring, and improve the quality.

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0019] 1. According to the structure of the steel ring, design the pressure roller curve of the steel ring:

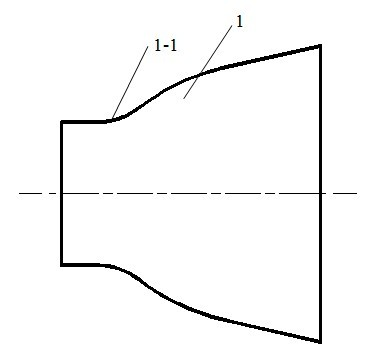

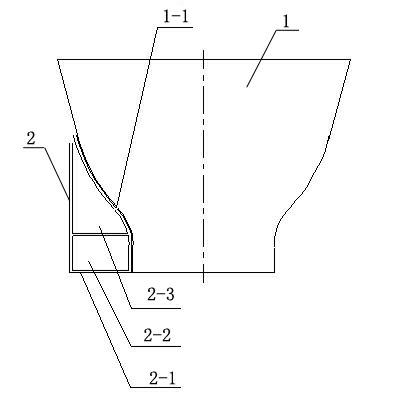

[0020] refer to figure 1 , prepare the pressure roller according to the requirement that the curve 1-1 of the steel ring pressure roller 1 coincides with the pressing surface of the steel ring 2, and machine the contact point of the original pressure roller and the steel ring to make it a contact line;

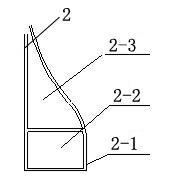

[0021] refer to figure 2 , the steel ring 2 is made up of wrapping cloth 2-1, steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com