Integrated vacuum negative-pressure three-level dust removal system

A vacuum negative pressure and dust removal system technology, which is applied in the direction of non-variable pumps, combined devices, buildings, etc., can solve the problem that dust removal equipment cannot meet the needs of low-profile bolter rigs, achieve light weight, and improve dust removal efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

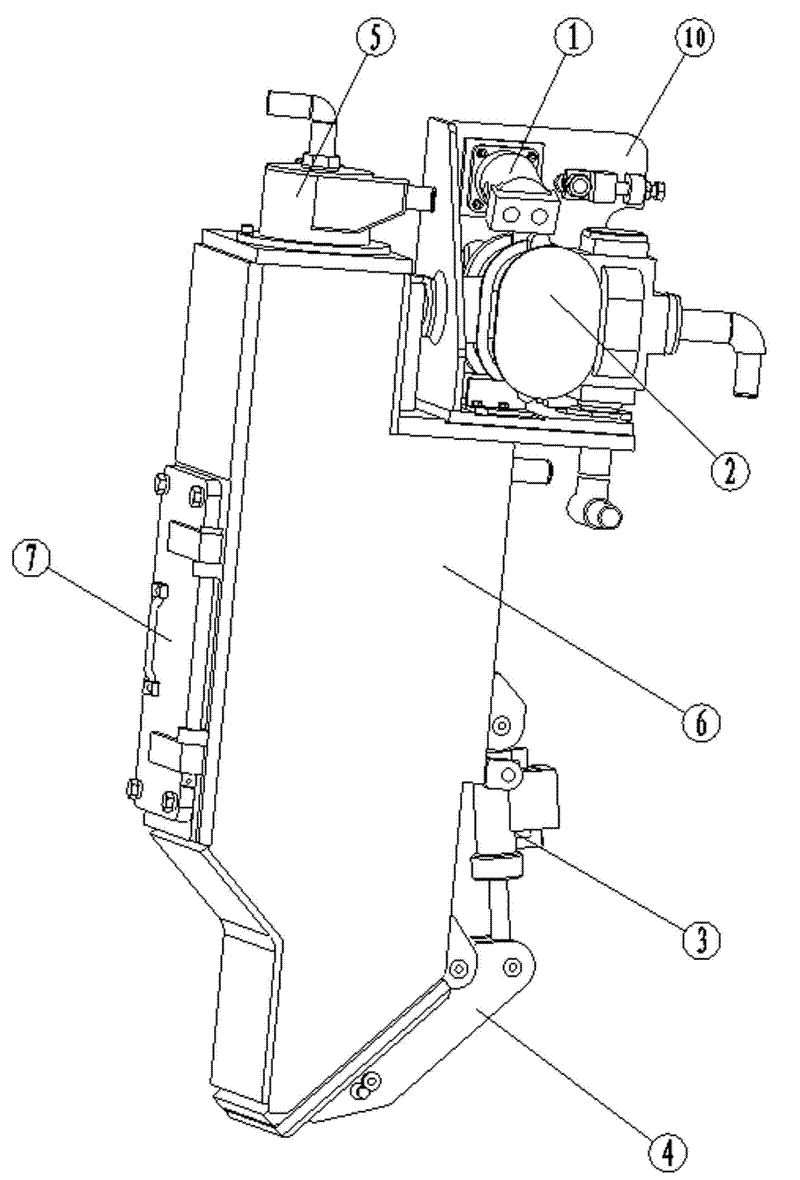

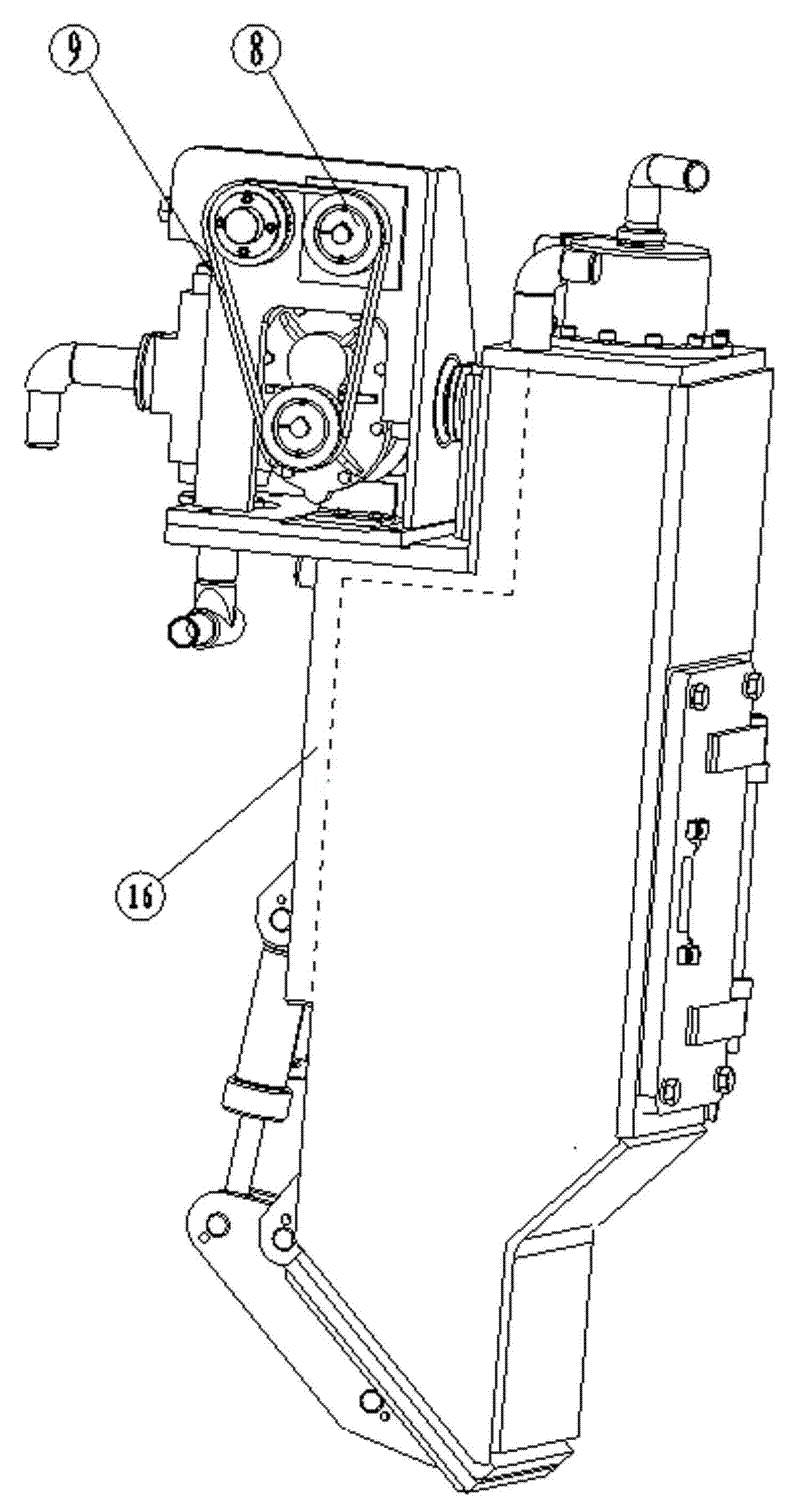

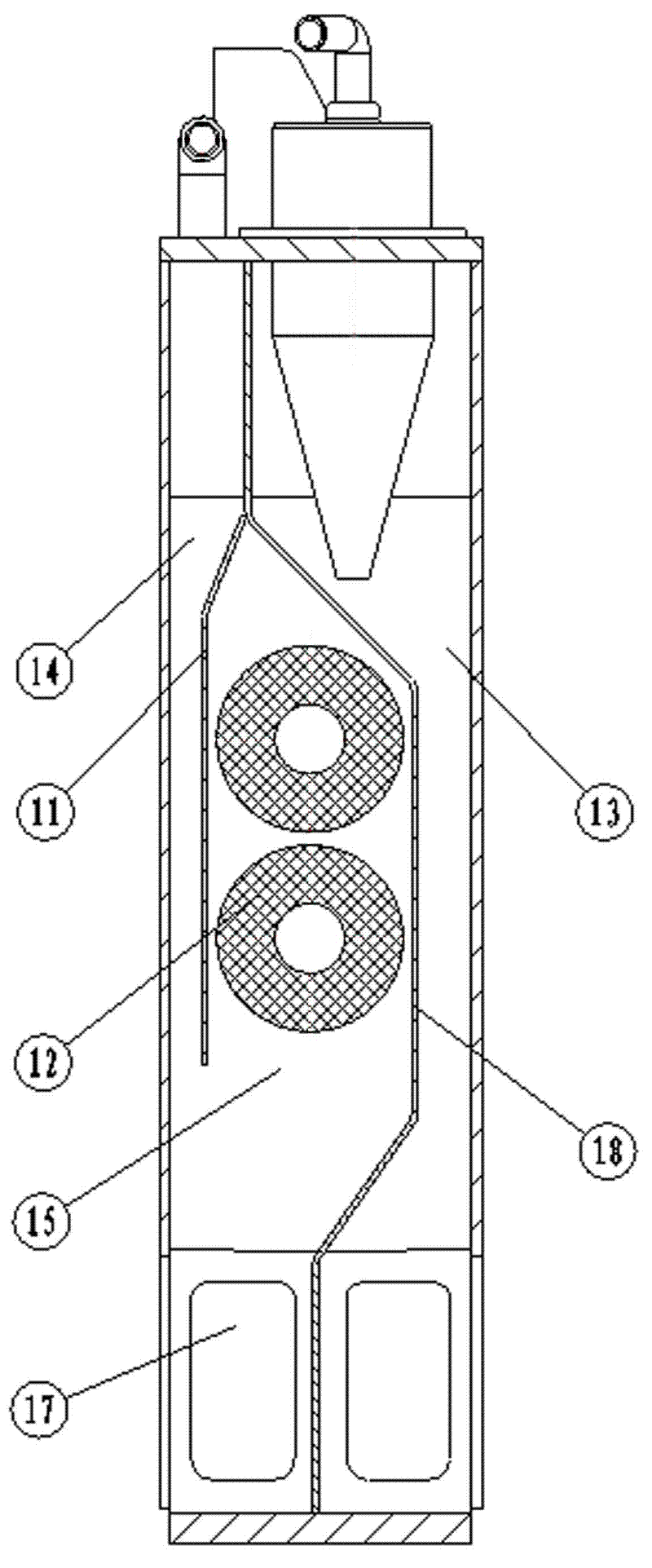

[0015] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0016] 1. Improved the structure of the dust removal box (dust removal box integration), such as image 3 As shown, the interior of the dust removal box 6 is divided into three dust removal areas by the guide partition I11 and the guide partition II18, including the cyclone dust removal area 13, the gravity dust removal area 14, and the filter element dust removal area 15. The dust removal areas are sealed and isolated from each other. The top of the gravity dust removal area 14 is provided with an air inlet connected to the air outlet of the cyclone 5, the filter element dust removal area 15 is provided with the middle and lower part of the dust removal box 6, and the guide partition I11 between the filter element dust removal area 15 and the gravity dust removal area 14 is provided with Several through holes. The exhaust area 16 has a sealed str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com