Mounting structure of pin shaft, jib structure of engineering machinery and concrete pumping device

A technology of installation structure and construction machinery, applied in the directions of mechanical equipment, shafts and bearings, pivots, etc., can solve the problems of weight reduction of booms and other equipment, affecting assembly size, poor stability of pin shaft connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

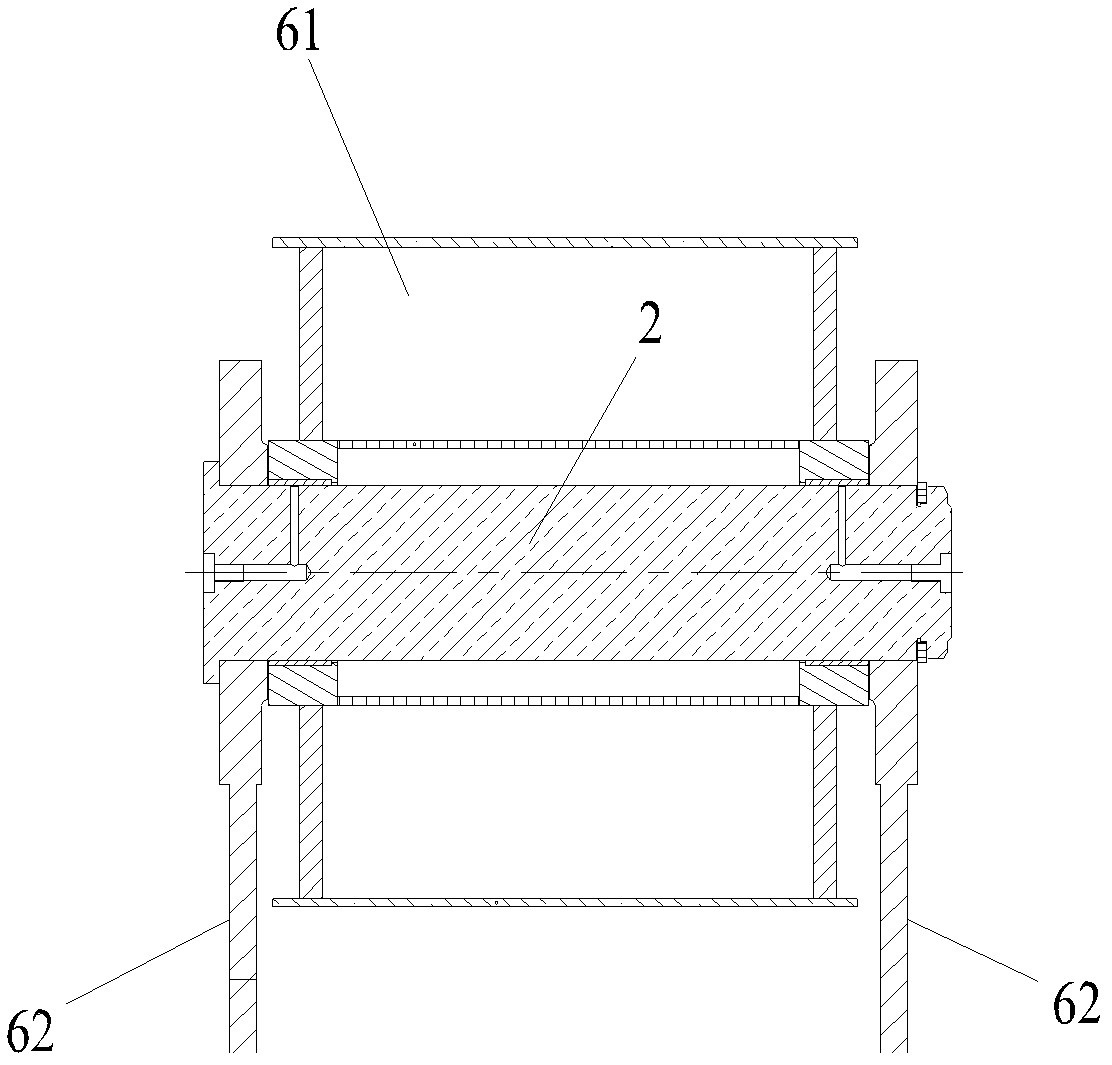

[0045] In order to overcome the problem of the mounting structure of the pin shaft in the prior art, such as Figure 3 to Figure 5 As shown, a pin installation structure is provided, including a connected object 1 and a pin shaft 2 passing through the connected object 1, the two ends of the pin shaft 2 are supported by the connected object 1, and the pin shaft installation structure also includes a support The supporting part 4 of the bearing pin 2 is located between the two supported ends of the pin shaft 2 .

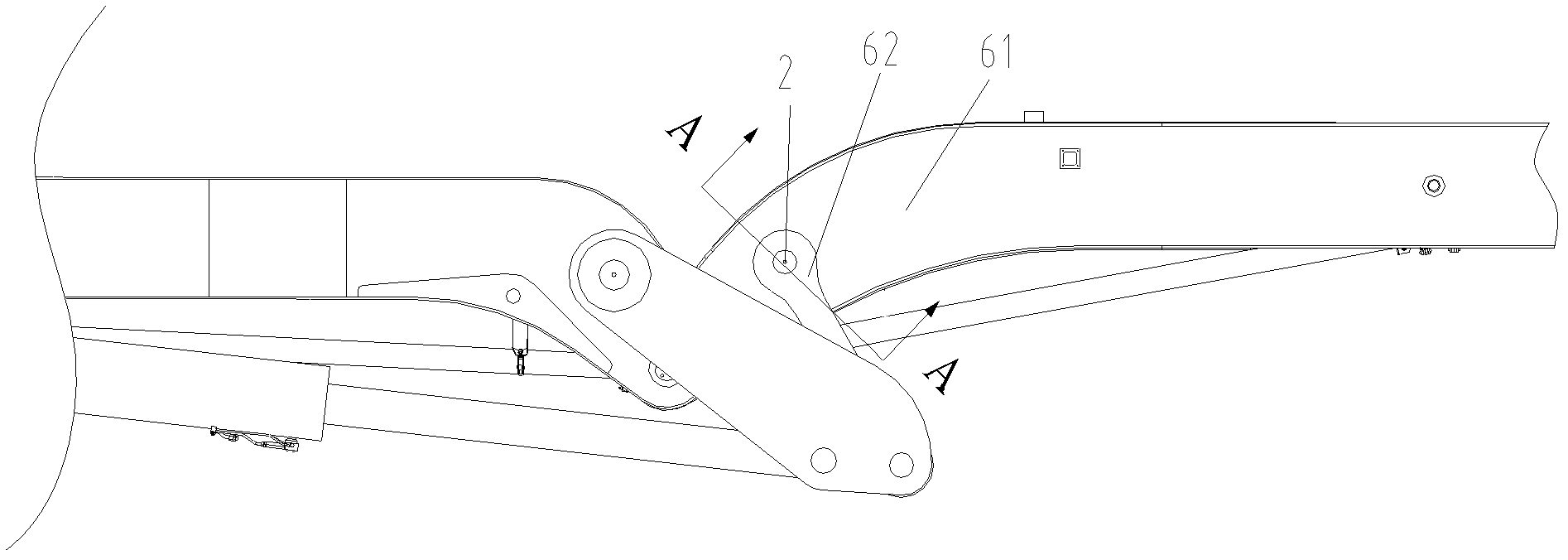

[0046] Specifically, in the preferred embodiment of the present invention, in order to adapt to the articulation between the arm section 61 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com