Aluminum profile

An aluminum profile and regular octagon technology, applied in the field of main frame aluminum profiles, can solve the problems of poor connection structure stability, decreased precision, easy invention and rotation of round pipe fittings, etc., and achieves the effect of easy matching and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

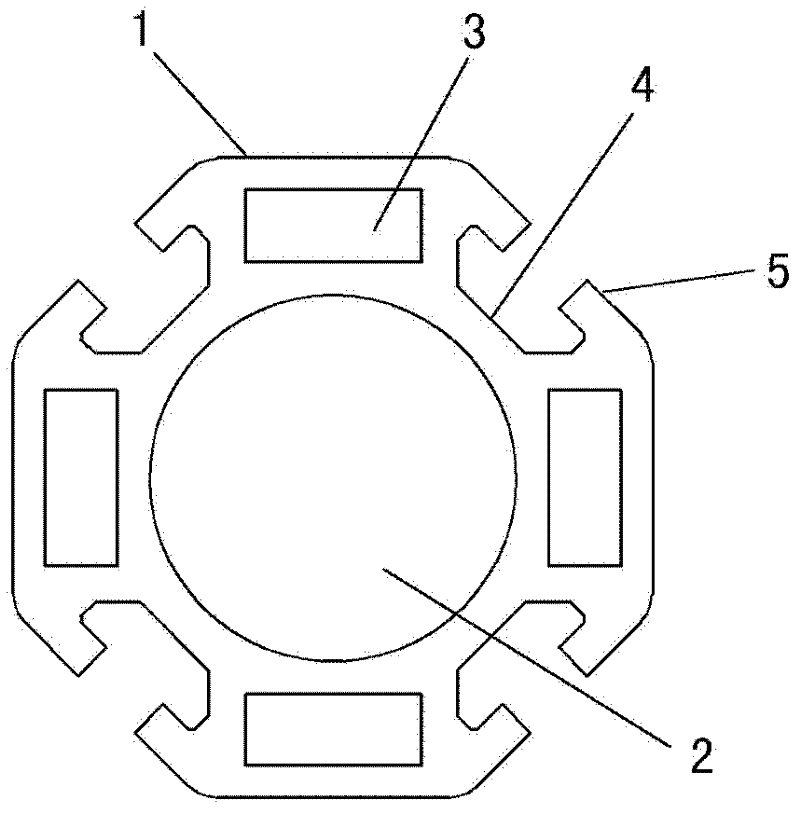

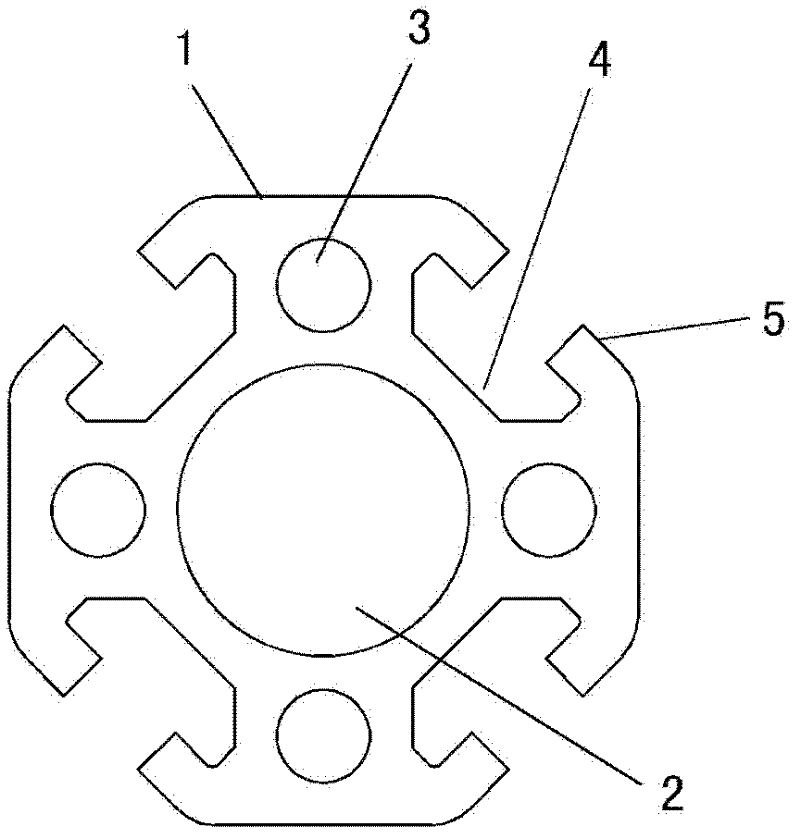

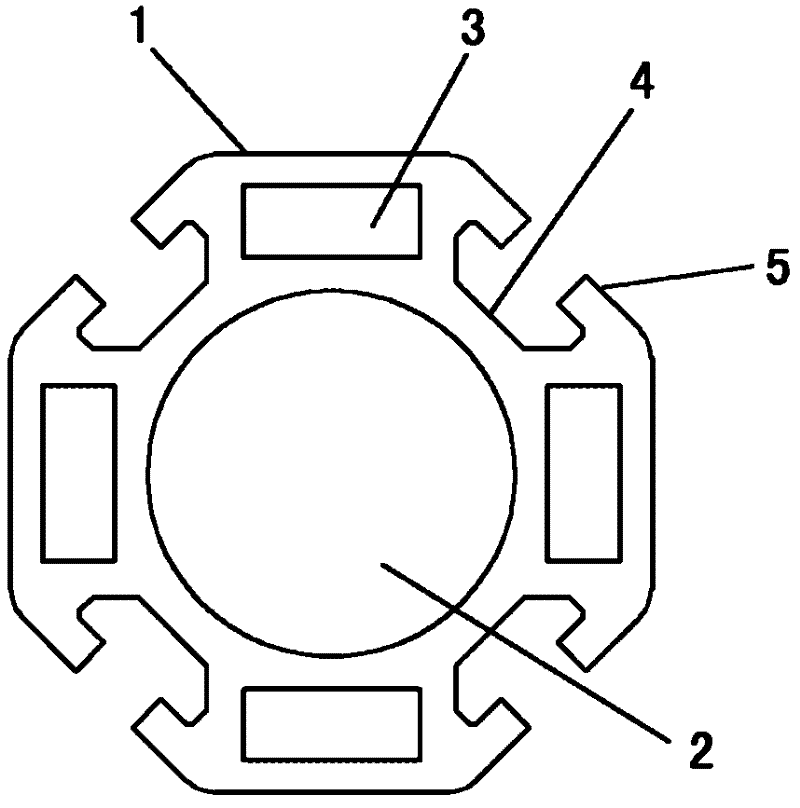

[0014] The structural form of the aluminum profile 1 in this embodiment is that the outer periphery of the cross section of the columnar aluminum profile is set to be a regular octagon, and the center is a circular through hole 2 along the axial direction. The regular octagonal structure and the planar structure Other connecting parts can form a stable fit without rotation; the central circular through hole 2 not only reduces the weight of the aluminum profile, but also strengthens the mechanical properties of the aluminum profile in terms of bending and torsion resistance, and facilitates the connection of air pipes and cables. Trace arrangement.

[0015] On the eight sides of the regular octagon, a nut groove 4 can be arranged on every other side, and the nut groove side 5 where the nut groove 4 is located can be connected with other connectors by bolts; the four nut grooves 4 are in the The periphery of the through holes 2 is evenly distributed; the nut groove 4 is used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com