Direct backlight module and television

A backlight module and direct-lit technology, which is applied in the field of televisions to achieve cost-saving, combination-saving and ample space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

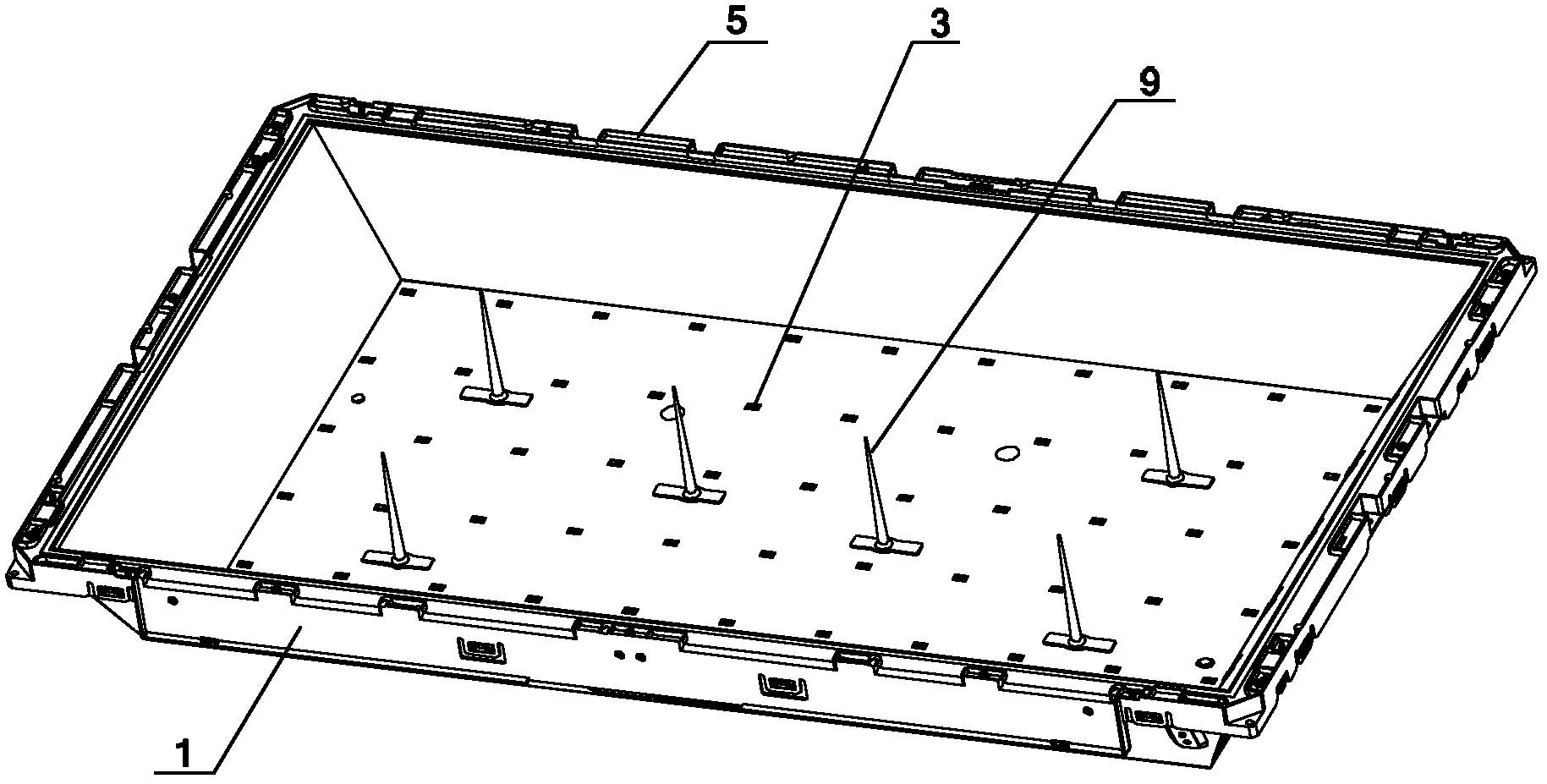

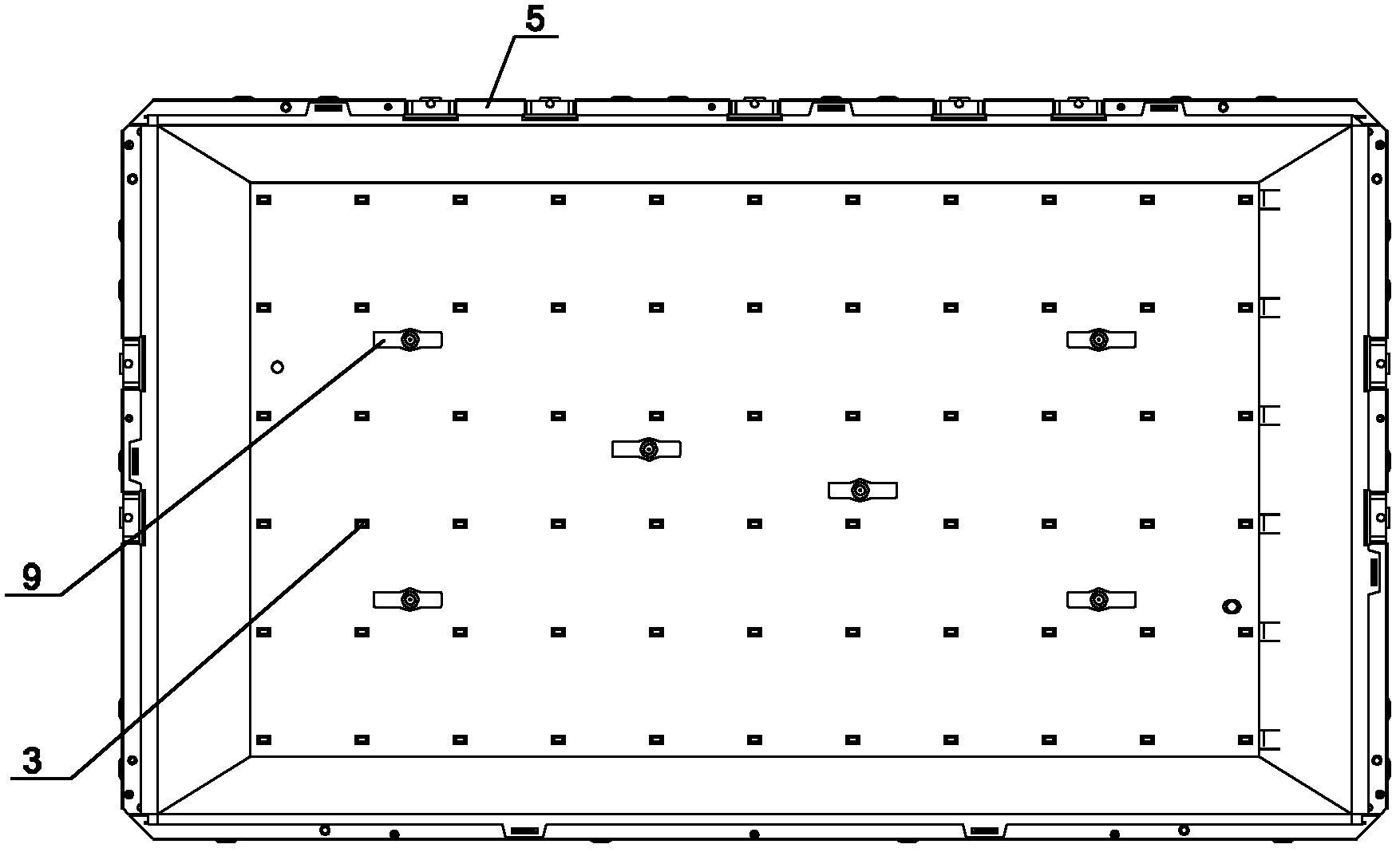

[0021] Figure 5 , Figure 6 It is a structural schematic diagram of an embodiment of the backlight module according to the present invention.

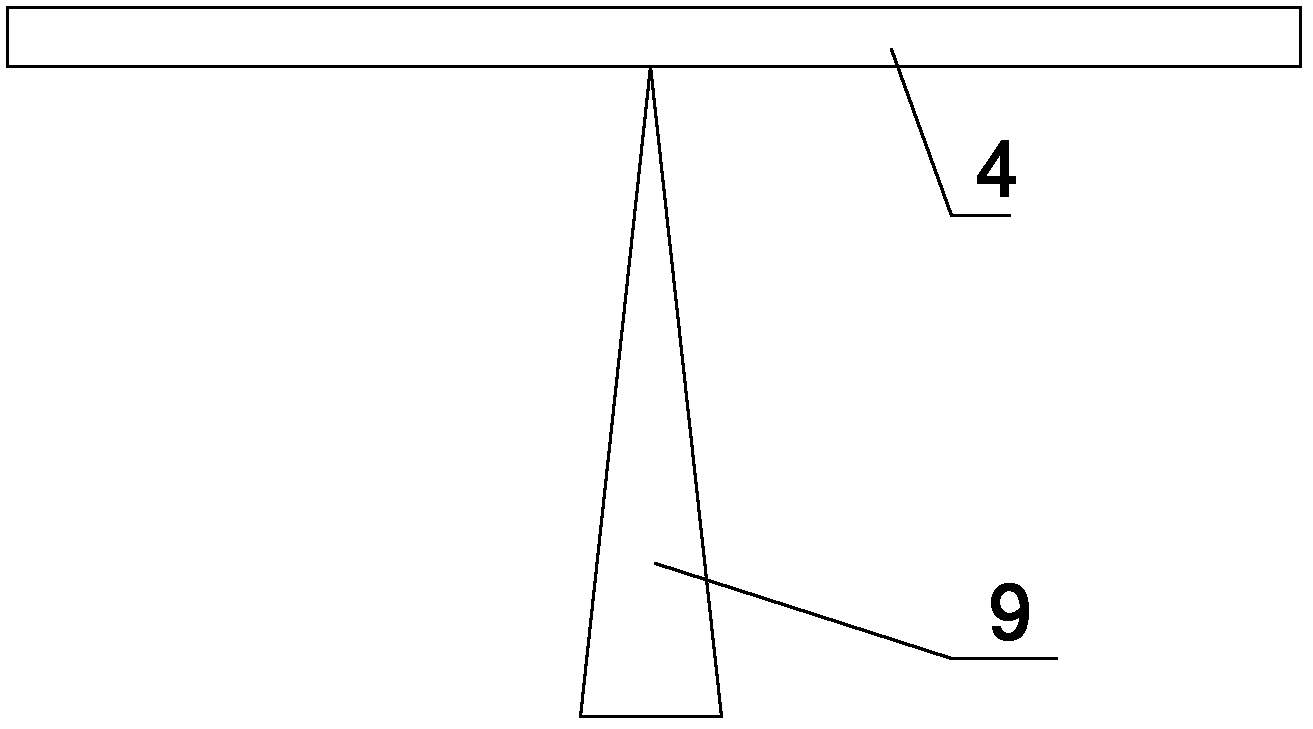

[0022] Such as Figure 5 , Figure 6 As shown, an embodiment of the present invention provides a direct-lit LED backlight module, including an open backplane 1, a reflector 2, an LED light source 3, a diffusion plate 4, and a plastic frame 5. The backplane 1 The inner surface of the backboard 1 is provided with the reflector 2, the LED light source 3 is installed on the bottom of the backboard 1 and passes through the reflector 2, and the open end of the backboard 1 is provided with a supporting platform 11, so The plastic frame 5 is installed around the support platform 11 and fixed on the support platform 11, the diffusion plate 4 is installed on the support platform 11 and fixed by the plastic frame 5, by adjusting the diffusion plate 4 is the area of the contact portion with the support platform 11 on the back plate 1 to sup...

Embodiment 2

[0041] Figure 7 , Figure 8 It is a structural schematic diagram of another embodiment of the backlight module according to the present invention.

[0042] Such as Figure 7 , Figure 8 As shown, another embodiment of the present invention provides another direct-lit LED backlight module, which includes an open back plate 1, a reflector 2, an LED light source 3, a diffuser plate 4, and a plastic frame 5. The inner surface of the board 1 is provided with the reflector 2, the LED light source 3 is installed on the bottom of the backboard 1 and passes through the reflector 2, and the open end of the backboard 1 is provided with a supporting platform 11 , the plastic frame 5 is installed around the support platform 11 and fixed on the support platform 11, the diffusion plate 4 is installed on the support platform 11 and fixed by the plastic frame 5, by placing the The diffuser plate 4 is pasted on the supporting platform 11 to support the diffuser plate 4 .

[0043] Each sid...

Embodiment 3

[0051] This embodiment is basically the same as embodiment one and embodiment two, and its difference is:

[0052] This embodiment provides another direct-lit LED backlight module, which includes an open backplane 1, a reflector 2, an LED light source 3, a diffusion plate 4, and a plastic frame 5. The inner surface of the backplane 1 is provided with The reflector 2, the LED light source 3 are installed on the bottom of the backboard 1 and pass through the reflector 2, the open end of the backboard 1 is provided with a support platform 11, and the plastic frame 5 is installed Around the support platform 11 and fixed on the support platform 11, the diffusion plate 4 is installed on the support platform 11 and fixed by the plastic frame 5, by adjusting the diffusion plate 4 and the back The area of the contact portion of the support platform 11 on the plate 1 and the diffusion plate 4 is pasted on the support platform 11 to support the diffusion plate 4 .

[0053] This soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com