a radiator

A radiator and combined technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of easy corrosion, narrow water channels, large water resistance and easy blockage, etc., and achieve a simple and practical manufacturing process , long service life and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

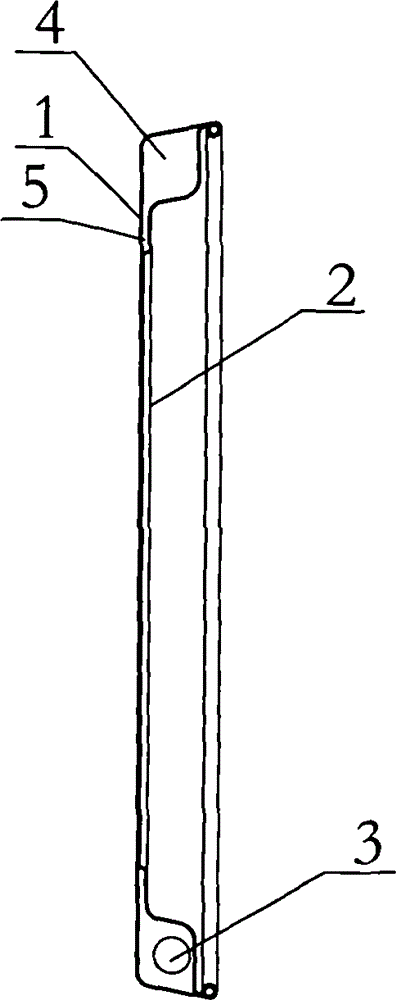

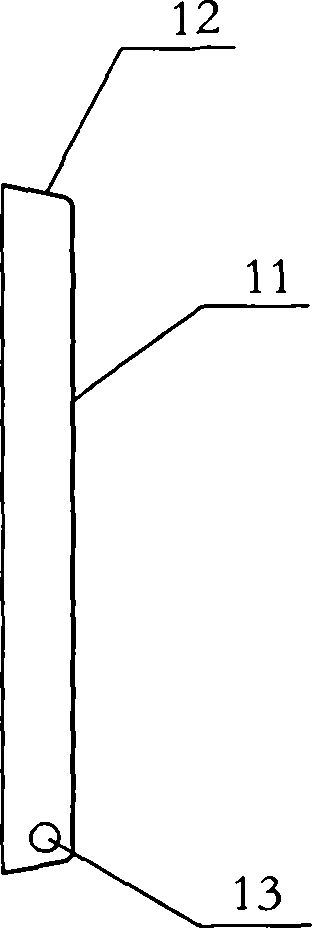

[0016] With reference to accompanying drawing, radiator of the present invention comprises radiator panel 1 and radiator backboard 2, and radiator panel is that orthographic projection is rectangle, and horizontal and vertical section is the rectangular groove of equilateral trapezoid; Radiator backboard is that bottom surface 21 is less than The bottom surface of the radiator panel 11, the angle of the flange 24 is the same as the angle of the radiator panel flange 12. There is an outer edge 23 parallel to the bottom surface on the groove edge of the radiator back plate, and the outer edge of the outer edge is folded out at an angle of inclination. The connection edge 22 with the same inclination angle as the folded edge 24, the outer contour dimension of the connection edge coincides with the outer contour dimension of the radiator panel, and there are convex ribs 25 arranged in parallel at equal intervals on the bottom surface of the radiator backplane, and the radiator backp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com