Viscose filtering resistance detection method

A detection method and viscose technology, which is applied in the textile field, can solve the problems of large error in the final result, low detection stability, and influence on the detection result, and achieve high accuracy, facilitate promotion and implementation, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

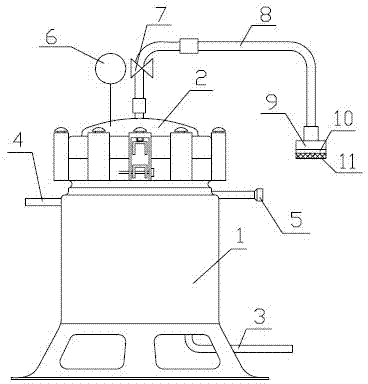

[0020] The viscose filter resistance detection method adopts a viscose filter resistance measuring device for measurement. The device includes a cylinder 1 with a top opening, a sealing cover 2 installed at the opening of the cylinder 1, and a bottom of the cylinder 1. Jacket water outlet 3, jacket water inlet 4 and compressed air inlet 5 are opened on the upper part of cylinder body 1, pressure measuring gauge 6 and viscose tube 8 with valve 7 are connected to the sealing cover 2, the viscose tube One end of 8 extends into cylinder 1, and the other end of viscose tube 8 is covered with filter 9; said filter 9 includes filter cloth 10 and stainless steel wire mesh 11 supporting filter cloth 10;

[0021] The specific detection steps are as follows:

[0022] A. Remove the sealing cover 2 at the opening of the cylinder body 1, add viscose into the cylinder body 1, then cover the sealing cover 2 to seal it, and feed air into the compressed air inlet 5 on the cylinder body 1, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com