A waste solid waste treatment system

A waste treatment system and solid waste technology, applied in grain treatment, special treatment targets, anaerobic digestion treatment, etc., can solve problems such as unsatisfactory rolling effects, inability to protect aeration tubes, and overloading of rolling motors. Achieve compact structure, prevent long-term overloading, and facilitate rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

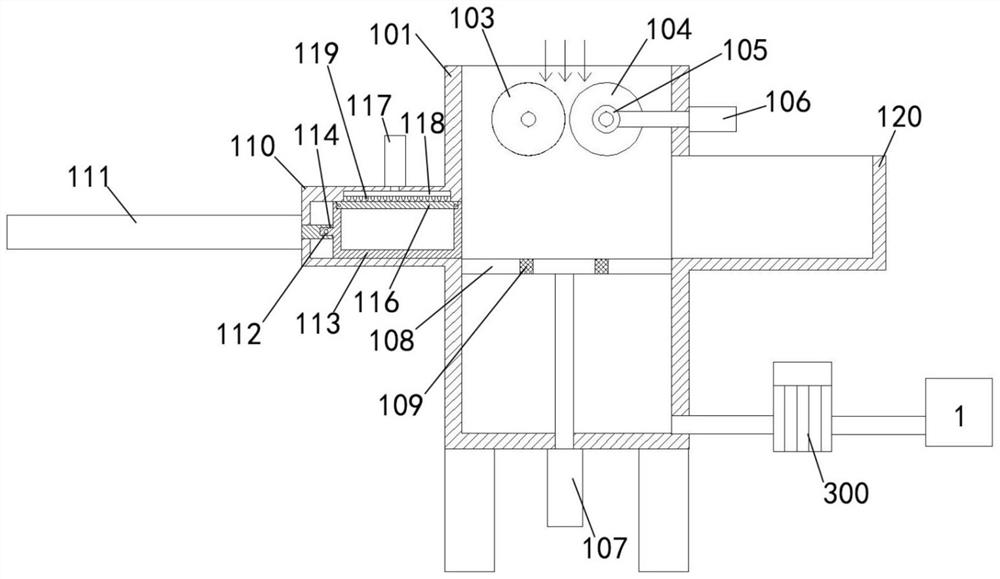

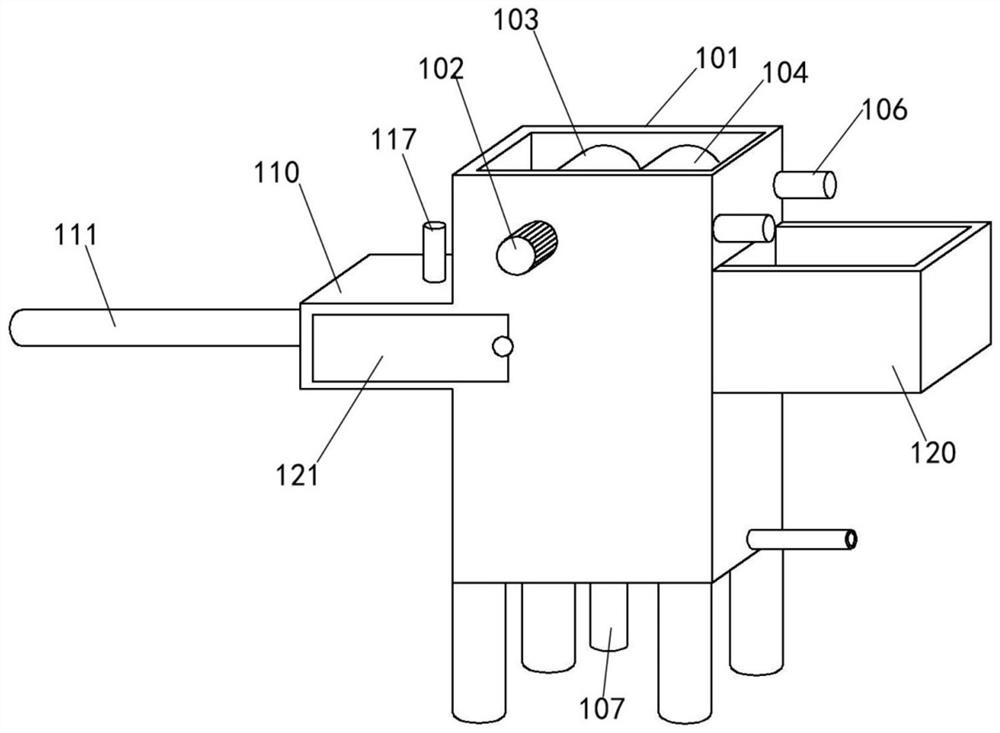

[0041] Example: such as Figure 1-6 The solid waste treatment system shown includes a crushing device 100 and a permeate treatment device 200. While the waste is crushed by the crushing device 100, the permeate is separated and sent to the UASB of the permeate treatment device 200 by a delivery pump 300. The reactor 1, the crushing device 100 includes a crushing shell 101, and the crushing shell 101 has a built-in active crushing roller 103 driven by a driving motor 102. Both sides of the rotating shaft of the matched driven crushing roller 104 are sleeved in the bushing 105, and each bushing 105 is fixedly connected to the output shaft of the avoidance pneumatic cylinder 106; the bottom wall of the crushing shell 101 is fixedly connected with the lifting pneumatic cylinder 107 The output shaft of the lifting pneumatic cylinder 107 is fixedly connected with a moving plate 108, and the moving plate 108 is provided with at least one penetration hole 109 (fine metal mesh is built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com