Patents

Literature

66results about How to "Reduce filter speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

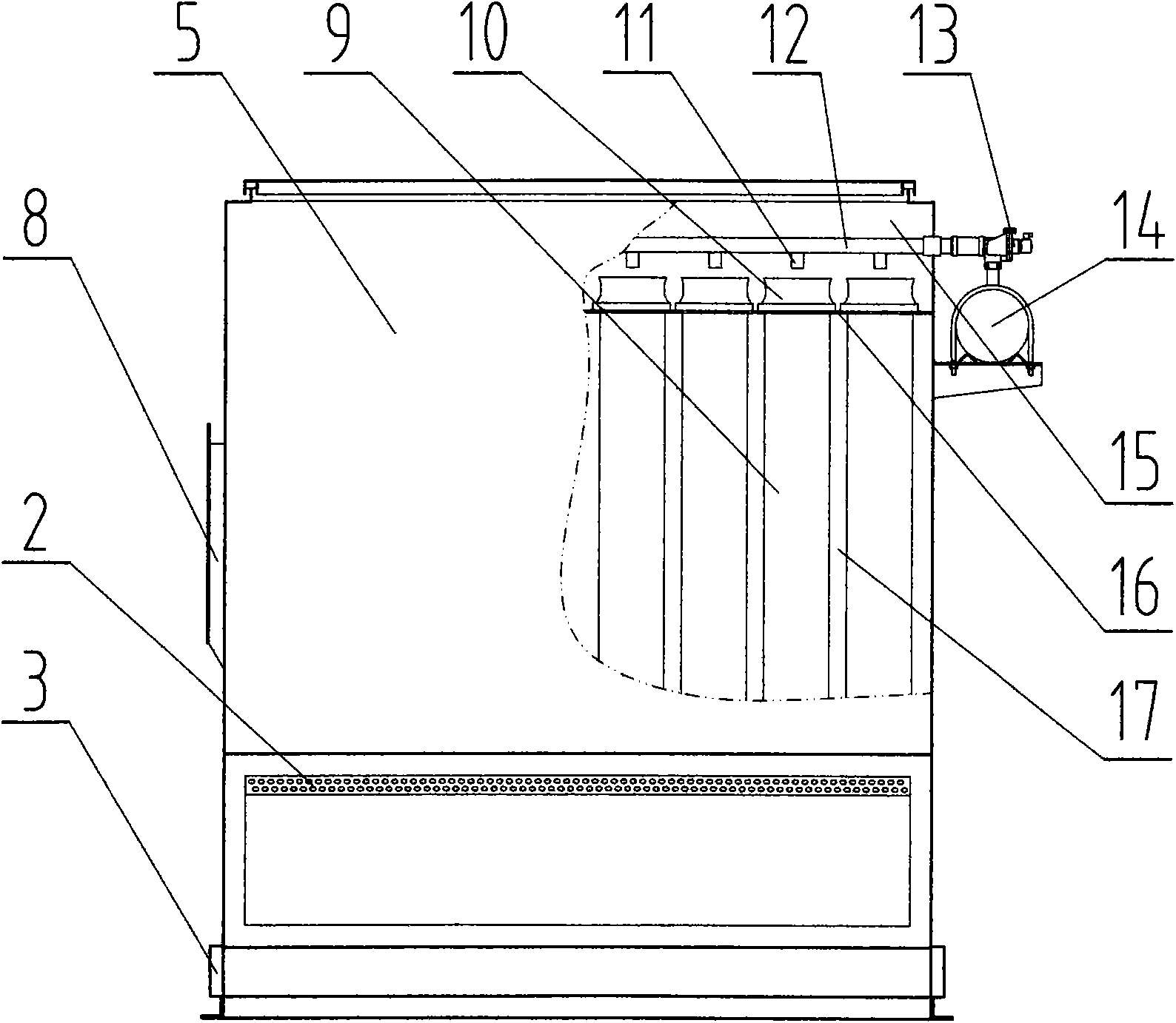

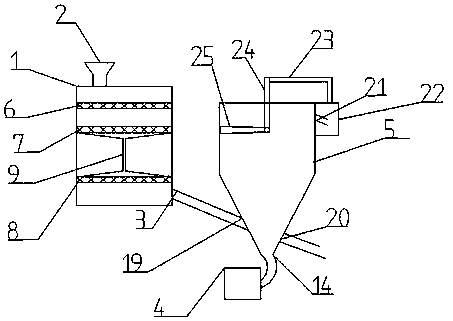

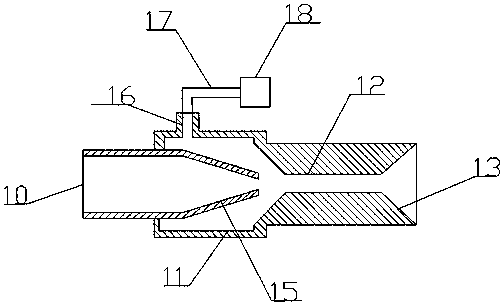

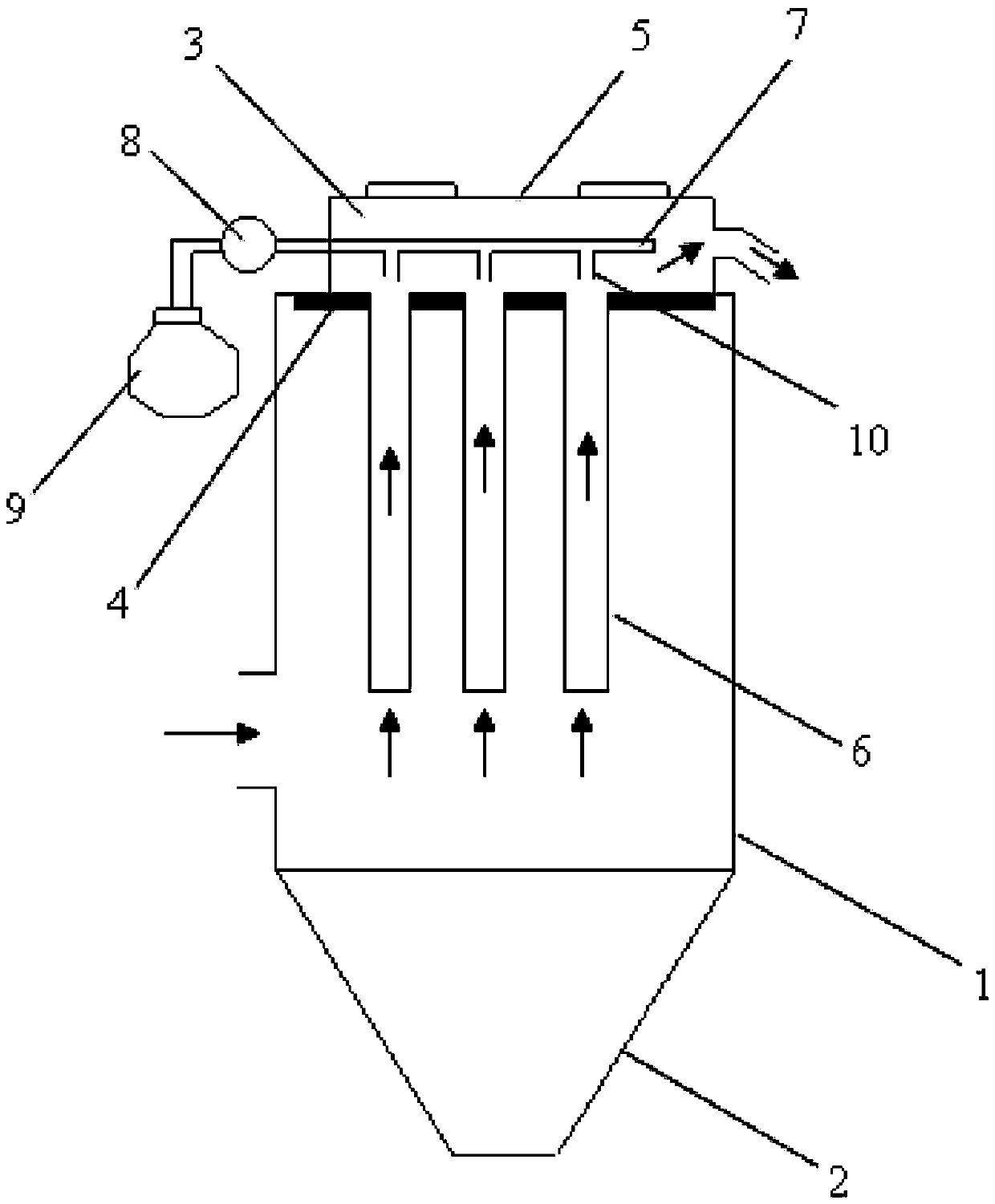

Explosion-proof-type dust collector for mine

InactiveCN101972577AShorten the lengthReduce volumeCombination devicesDispersed particle filtrationDust collectorStorage tank

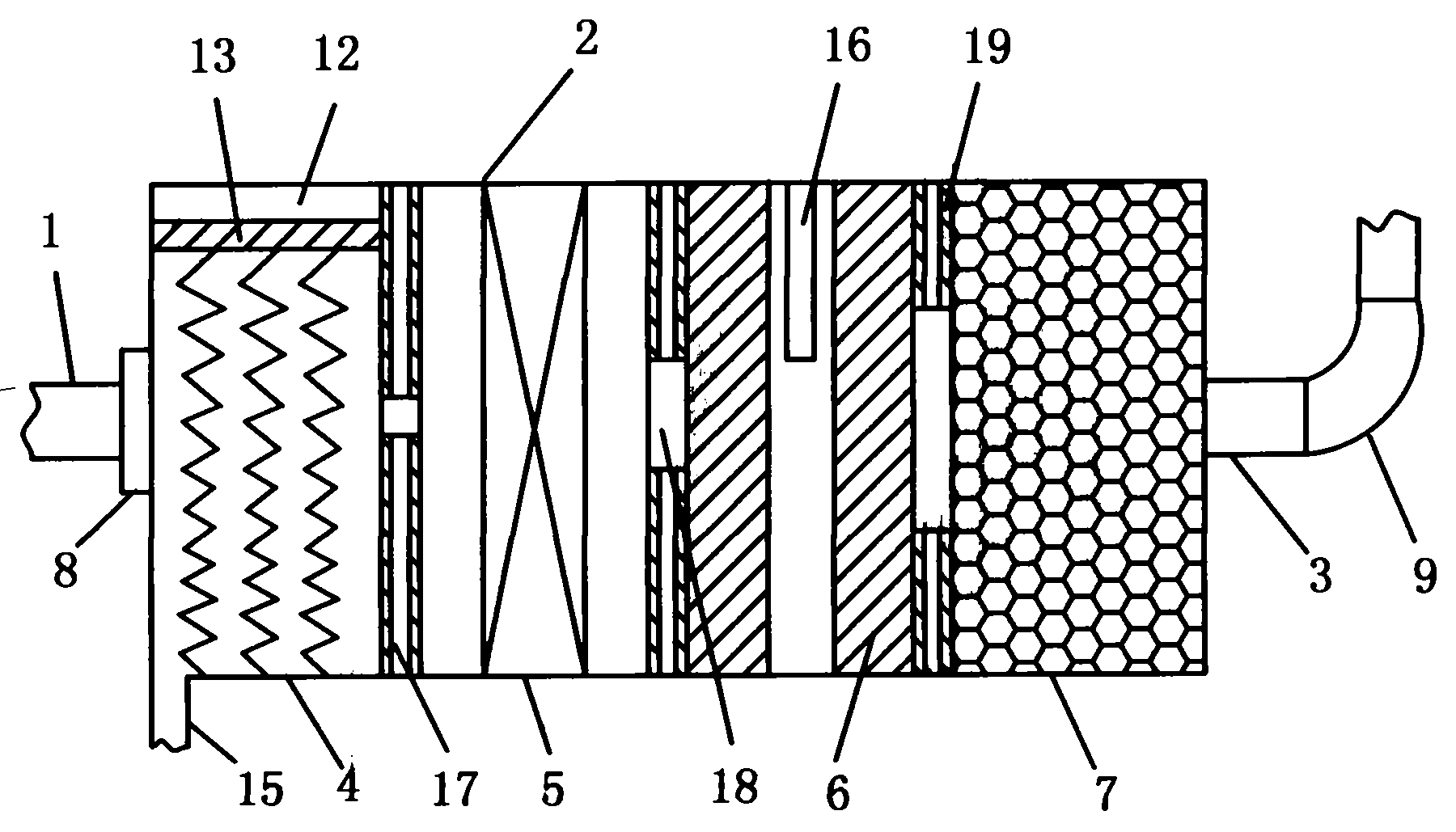

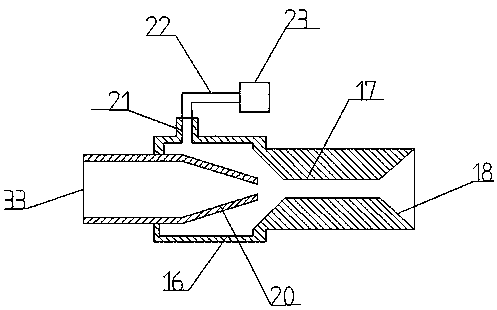

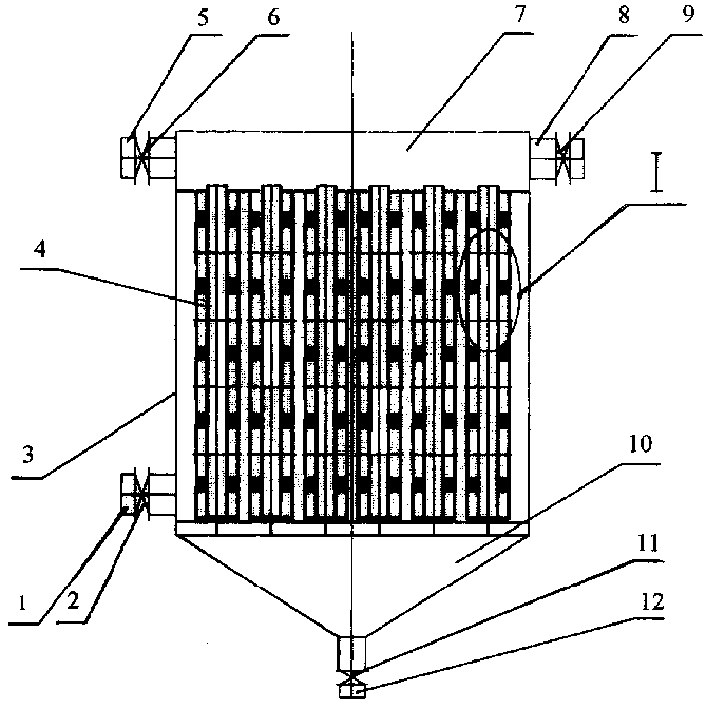

The invention discloses an explosion-proof-type dust collector for a mine, comprising a box body, a dust collecting and blowing system, an explosion-proof device, airflow distributing plates and an ash dumping drawer. The box body is in a cuboid structure and is provided with a tubesheet at the inner upper part, a space above the tubesheet forms an air purifying chamber, a space below the tubesheet forms a dust removing chamber, an air outlet is arranged at the rear end of the air purifying chamber, the dust collecting and blowing system is provided with a filter cartridge and a blowing device, the filter cartridge is arranged in the dust removing chamber, the tubesheet is arranged at the upper end of the filter cartridge, the blowing device is provided with a pulse valve, a blowing pipe, a nozzle, an air storage tank and a diversion device, the air storage tank is arranged at the outer side of the box body, the blowing pipe is located in the air purifying chamber and connected with the air storage tank through the pulse valve, the nozzle is arranged on the blowing pipe and arranged right above the upper end of the filter cartridge, the diversion device is arranged at the upper end of the filter cartridge, the airflow distributing plates are slantways arranged in the dust removing chamber and arranged below the lower end of the filter cartridge, the dust removing chamber is provided with an air inlet at the front end and provided with an ash dumping drawer hole at the lower part on one side, the ash dumping drawer is inserted in the hole, and the explosion-proof device is arranged at one side of the box body.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

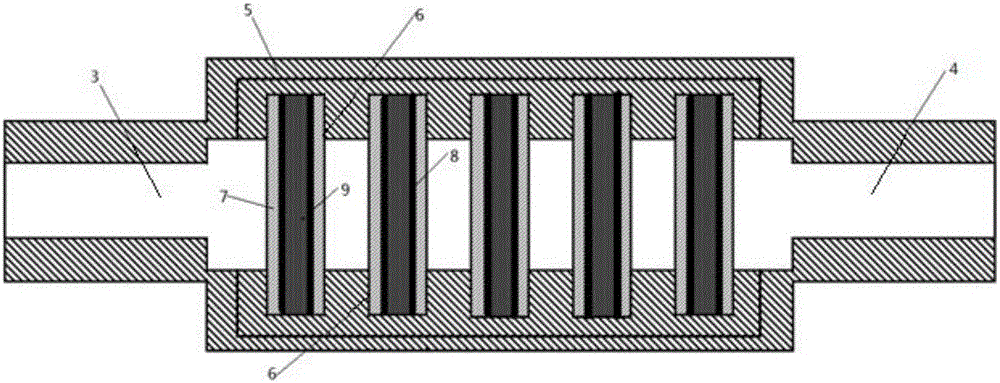

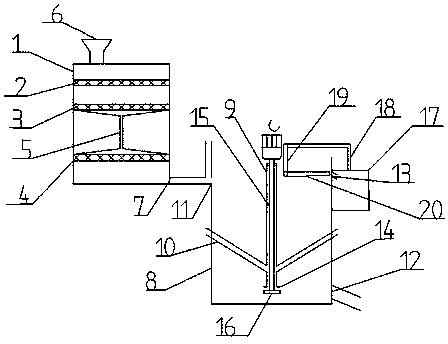

Dust removing and filtering device based on honeycomb ceramic filter elements

InactiveCN105944469ANo damage such as corrosionEasy to useHuman health protectionDispersed particle filtrationEngineeringControl valves

The invention provides a dust removing and filtering device based on honeycomb ceramic filter elements. The dust removing and filtering device comprises a shell, a dust cavity, a clean cavity, a dust removal fan and a compressed air cylinder, wherein a waste gas inlet is formed in one side of the shell, and a purified gas outlet is formed in the other side of the shell; the dust cavity is formed inside the shell and is communicated with one end of the waste gas inlet, and at least one ceramic filter body is arranged inside the dust cavity; the clean cavity is formed inside the shell, a cavity partition plate is mounted between the clean cavity and the dust cavity and is connected with one end of the purified gas outlet; the dust removal fan is connected with the other end of the purified gas outlet; the compressed air cylinder is connected with the clean cavity through a pipeline, and a pulse inverse blow control valve is arranged on the pipeline. A dust removing and filtering device body adopts the ceramic filter body to filter dust, and the structural strength and the material strength of the dust removing and filtering device body are strong, so that the filter body cannot generate breakage, deformation, corrosion and other damages; as the pulse inverse blow control valve is adopted for controlling compressed air to flow out from the air cylinder so as to blow the dust on the ceramic filter body, the dust removing and filtering device provided by the invention has excellent dust down performance.

Owner:德州奥深节能环保技术有限公司

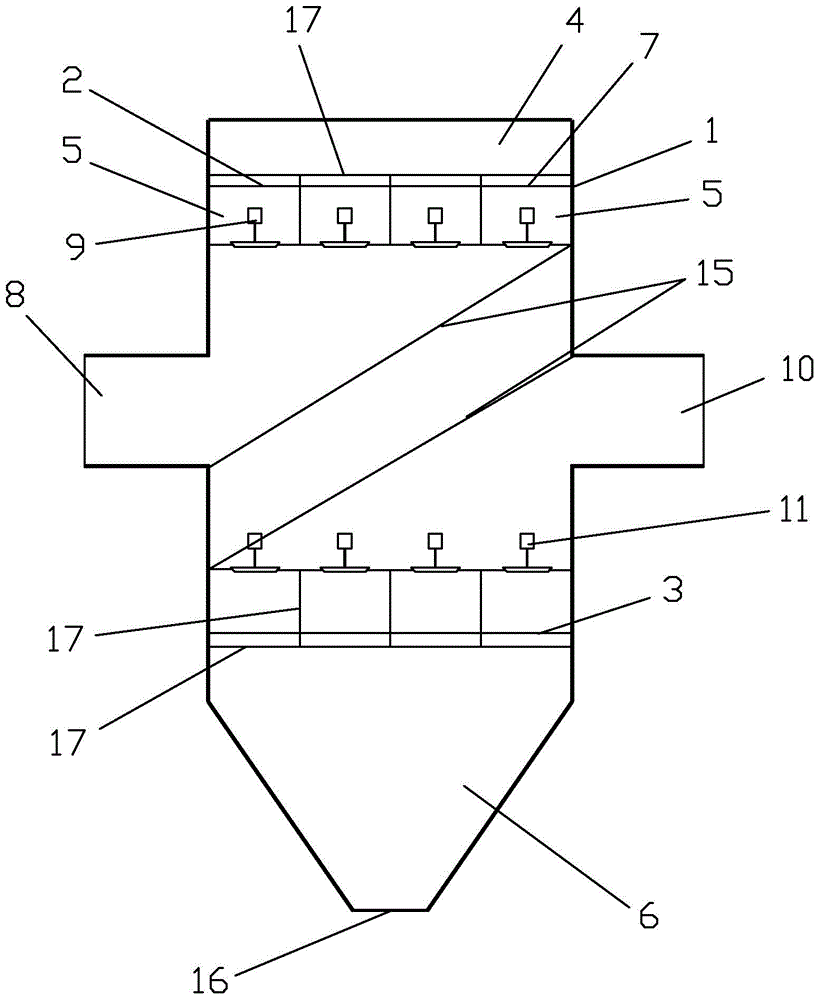

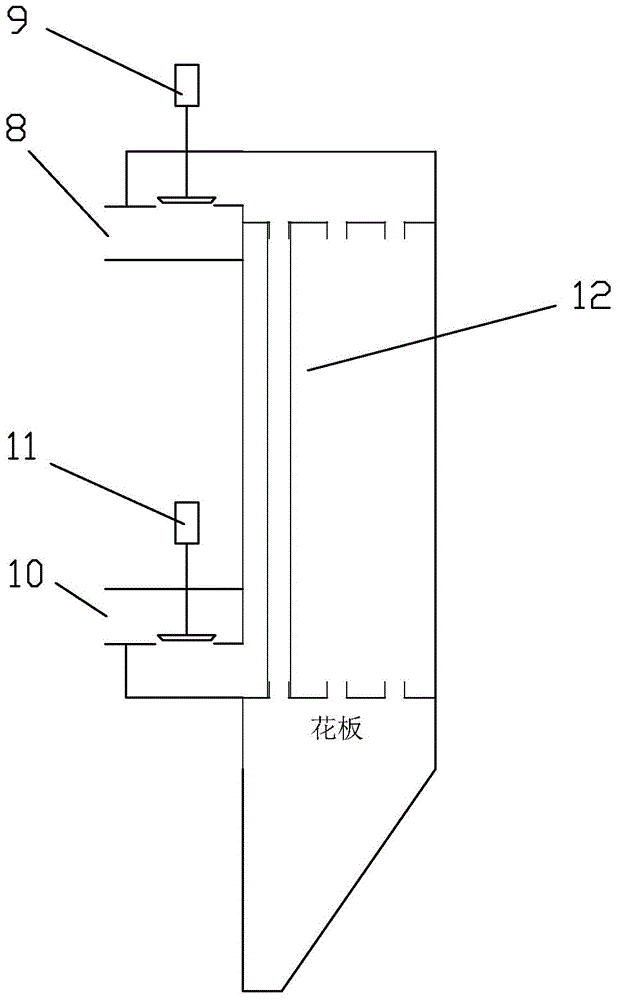

Ultra-low emission dust-removal apparatus and ash removal method thereof

ActiveCN104958964AReduce maintenance workloadLow operation and maintenance costsDispersed particle filtrationInlet channelFiltration

The present invention is an ultra-low emissions dust-removal apparatus and an ash removal method thereof. According to the apparatus, a dust removal device is divided into a plurality of filtration chambers, the upper portions of the filtration chambers are communicated with a gas inlet channel and are provided with gas inlet valves, the middle portions of the filtration chambers are communicated with a gas outlet channel and are provided with gas outlet valves, a vertical filtration bag is arranged between two tubesheets, an ash hopper is arranged below the lower tubesheet, and the internal of the filtration bag is communicated with the ash hopper. The ash removal method of the apparatus comprises: closing the gas inlet valve, maintaining the gas outlet valve at the opening state, closing the gas outlet valve after a few seconds, opening the gas inlet valve after a few seconds, closing the gas inlet valve for a few seconds after opening the gas inlet valve for a few seconds, and then opening the gas outlet valve so as to complete the one ash removal period. The apparatus has advantages of simple equipment, low maintenance workload, low operation and maintenance cost, and long filtration bag service life. According to the ash removal process, the pressures on both sides of the filtration bag produce the fluctuation through the opening and the closing of the gas inlet valve and the gas outlet valve so as to make the filtration bag deform and shake to form the self-cleaning type ash removal way having the ash removal effect, such that the operating energy consumption is substantially reduced.

Owner:FOSHAN S L P SPECIAL MATERIALS

Purifying treatment system for pollution gases and particles

The invention discloses a purifying treatment system for pollution gases and particles. The system comprises a gas inlet pipeline, a filter device and a gas outlet pipeline sequentially connected, wherein the filter device is provided with a silk screen filter, a draught fan, an air filter and a purifying adsorber connected in series. The system disclosed by the invention can overcome deficiencies in the prior art and effectively improve filtration and absorption of various pollution sources by the gas purifying device, and the system is convenient to maintain and long in service life.

Owner:HANGZHOU XIANGWAI ENVIRONMENTAL PROTECTION TECH CO LTD

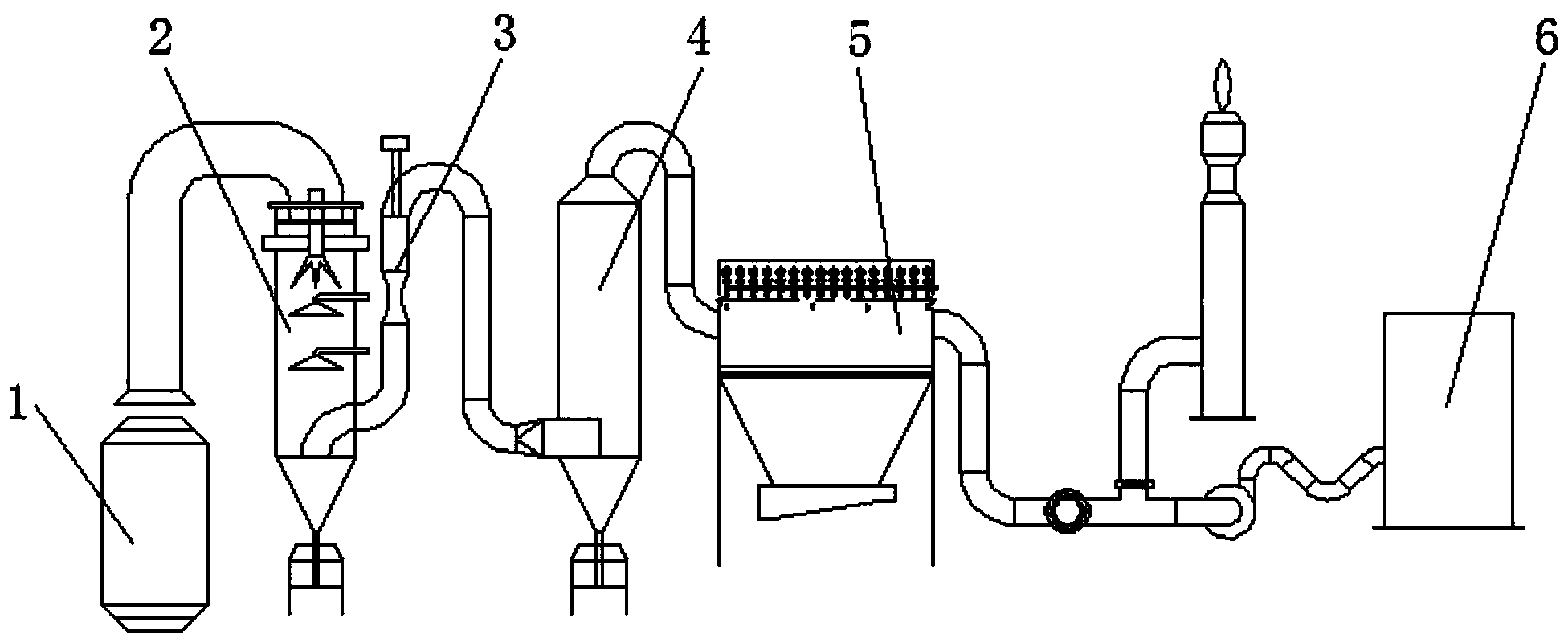

Blast furnace gas dust removal system

InactiveCN104031691AImprove dust removal efficiencySolve potential safety hazardsCombination devicesGas dust removalCombustionEngineering

The invention discloses a blast furnace gas dust removal system, belonging to the field of metallurgical furnace gas purification and dust removal. The blast furnace gas dust removal system aims to solve the problems of low dust removal efficiency, incapability of thoroughly avoiding gas explosion and the like in the existing dust removal mode. The dust removal system comprises a converter, a spray tower, a Venturi wet-process dust remover, a swirl dehydrator and a sintering board dust remover which are sequentially connected through a pipeline according to the gas flow sequence. Gas discharged from the converter enters the spray tower through the pipeline to be cooled, enters the Venturi wet-process dust remover to be subjected to rough dust removal, enters the swirl dehydrator to be dehydrated, and enters the sintering board dust remover to be subjected to fine dust removal and dehydration, and the finally obtained clean gas is classified according to needs and subjected to dispersed combustion or collected into a gasometer. By combining the rough dust removal of the Venturi wet-process dust remover and the fine dust removal and dehydration of the sintering board dust remover, the system greatly enhances the dust removal efficiency, and thoroughly solves the problem of potential safety hazard caused by gas explosion.

Owner:中节能天辰(北京)环保科技有限公司

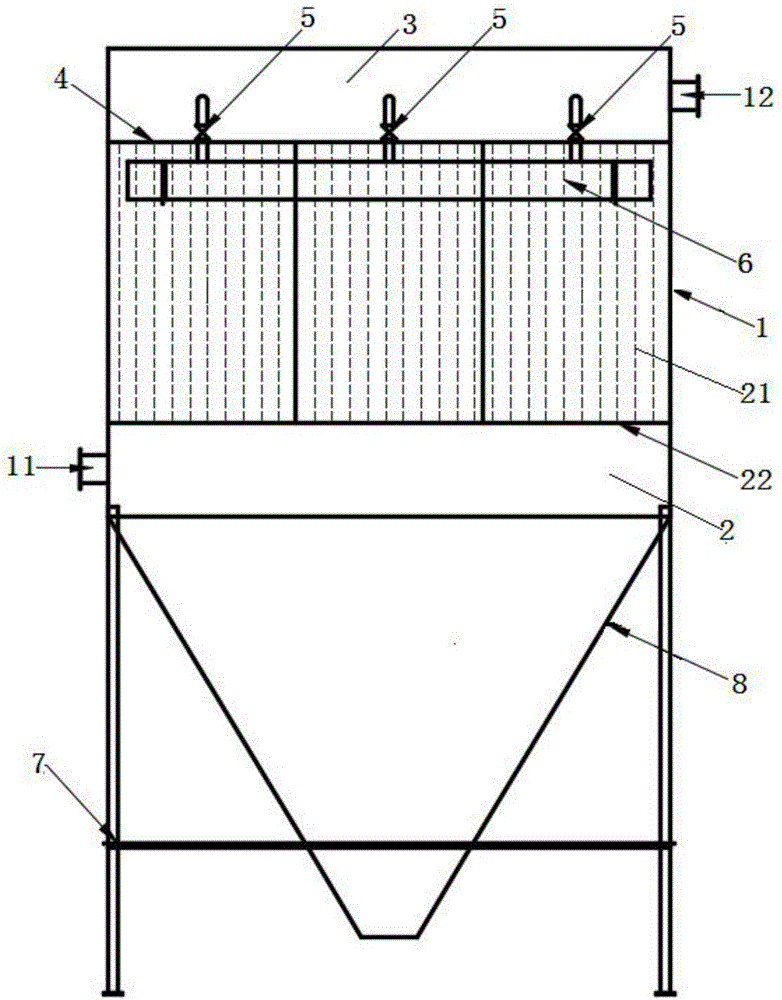

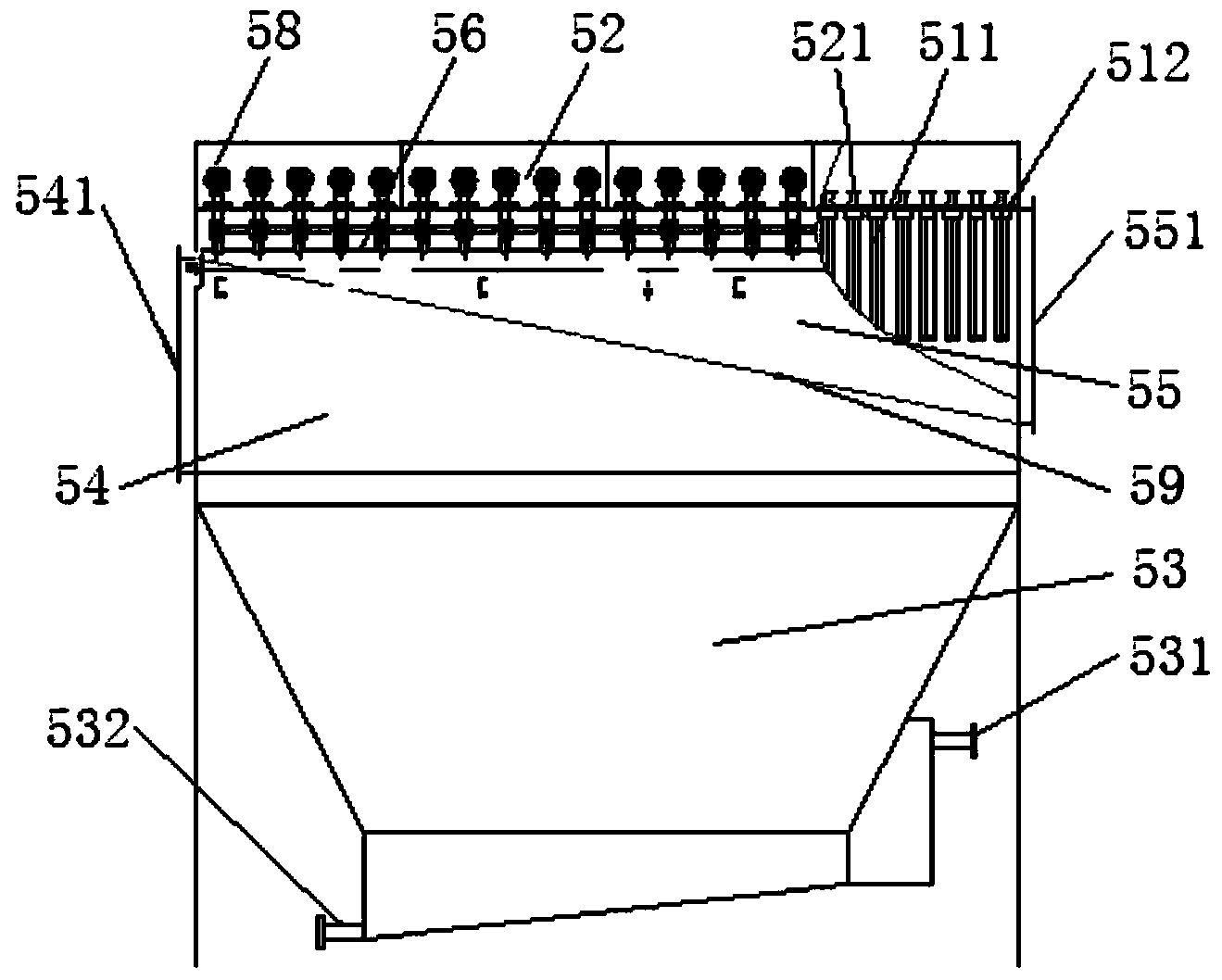

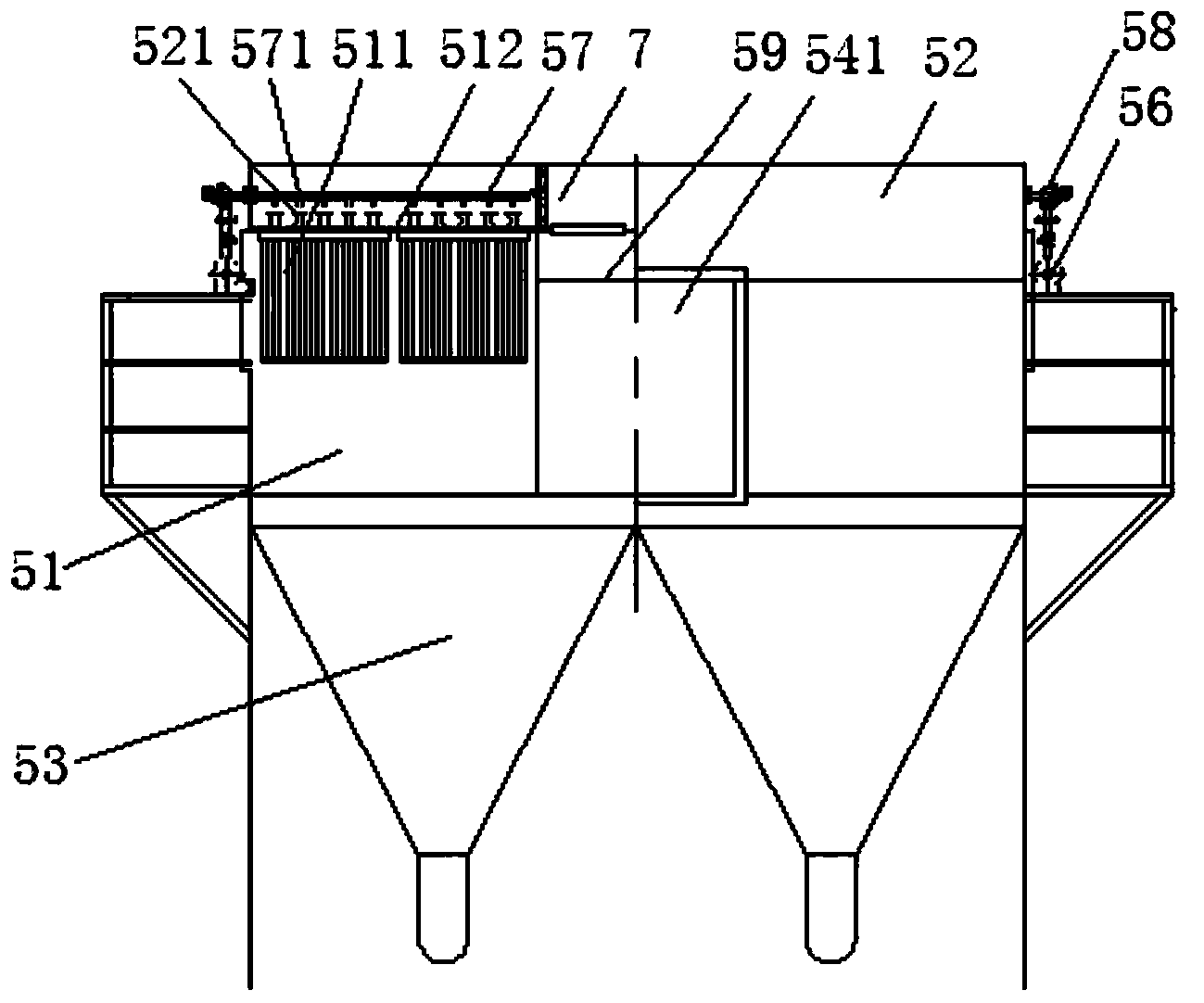

Semi-off-line deash bag dust-cleaning equipment

InactiveCN101254386ASmall filter resistanceExtended service lifeCombination devicesDispersed particle filtrationAir velocityFiltration

The invention discloses a half off-line bag filter, which belongs to the technology field of a dust remover. The invention aims to provide a half off-line bag filter which can improve the dust-cleaning efficiency, reduce the resistance of the dust remover, and avoid the damage to the dust remover body caused by the excessive negative pressure in an air cleaning room which is arranged at the upper part of a tubesheet when dust is cleaned. The invention is characterized in that an air cleaning room (9) arranged at the upper side of each row of filter bags of each bag chamber is internally provided with jet pipes (7) corresponding to each row of filter bags (4) in parallel, and the inlet ends of the jet pipes are connected with the outlets of pulse valves (6); nozzles (8) which are parallel with the jet pipes, have the same quantity as the filter bags the same centers with the filter bag mouths are arranged on the jet pipes; and a poppet valve (10) which has two working states of full open and semi close is arranged on a box body arranged on one side of the upper side of each bag chamber. Compared with the off-line dust cleaning, the half off-line bag filter cannot increase the filtration load of other bag chambers; compared with the on-line dust cleaning, the filtration velocity of the bag chambers and the velocity among the bag chambers are reduced by 1 / 2 to 2 / 3, thereby being more beneficial to the deposition of the discharged dust.

Owner:HEFEI CEMENT RES DESIGN INST

Carbon fiber automobile air conditioner filter

ActiveCN105854431AImprove mechanical propertiesSmall mechanical propertiesHuman health protectionDispersed particle filtrationActivated carbonCarbon fibers

The invention discloses a carbon fiber automobile air conditioner filter which comprises a filter cartridge, wherein the filter cartridge is provided with an air inlet and an air outlet, a plurality of slots are formed in the filter cartridge, and a filter frame is inserted into each slot. The carbon fiber automobile air conditioner filter is characterized in that magnetic attraction strips are arranged on the two inner sides of each filter frame respectively, wherein filter core materials are arranged between the magnetic attraction strips on the two sides; each filter core material comprises nonwoven fabric layers arranged on the surfaces of the two sides and blended from organic fiber filaments and activated carbon fiber filaments and a middle activated carbon fiber felt filtration and adsorption layer; the surface density of the blended nonwoven fabric layers is 30 to 200g / m<2>, and the surface density of the activated carbon fiber felt filtration and adsorption layers is 60 to 400g / m<2>. According to the carbon fiber automobile air conditioner filter, harmful substances in haze can be adsorbed and filtered in a targeted manner; with the adoption of a matched pluggable structure, a filter element can be flexibly replaced; moreover, a purification level can be freely regulated according to hazy weather, so that air quality in an automobile in different climatic environments can be effectively improved.

Owner:SHANDONG UNIV

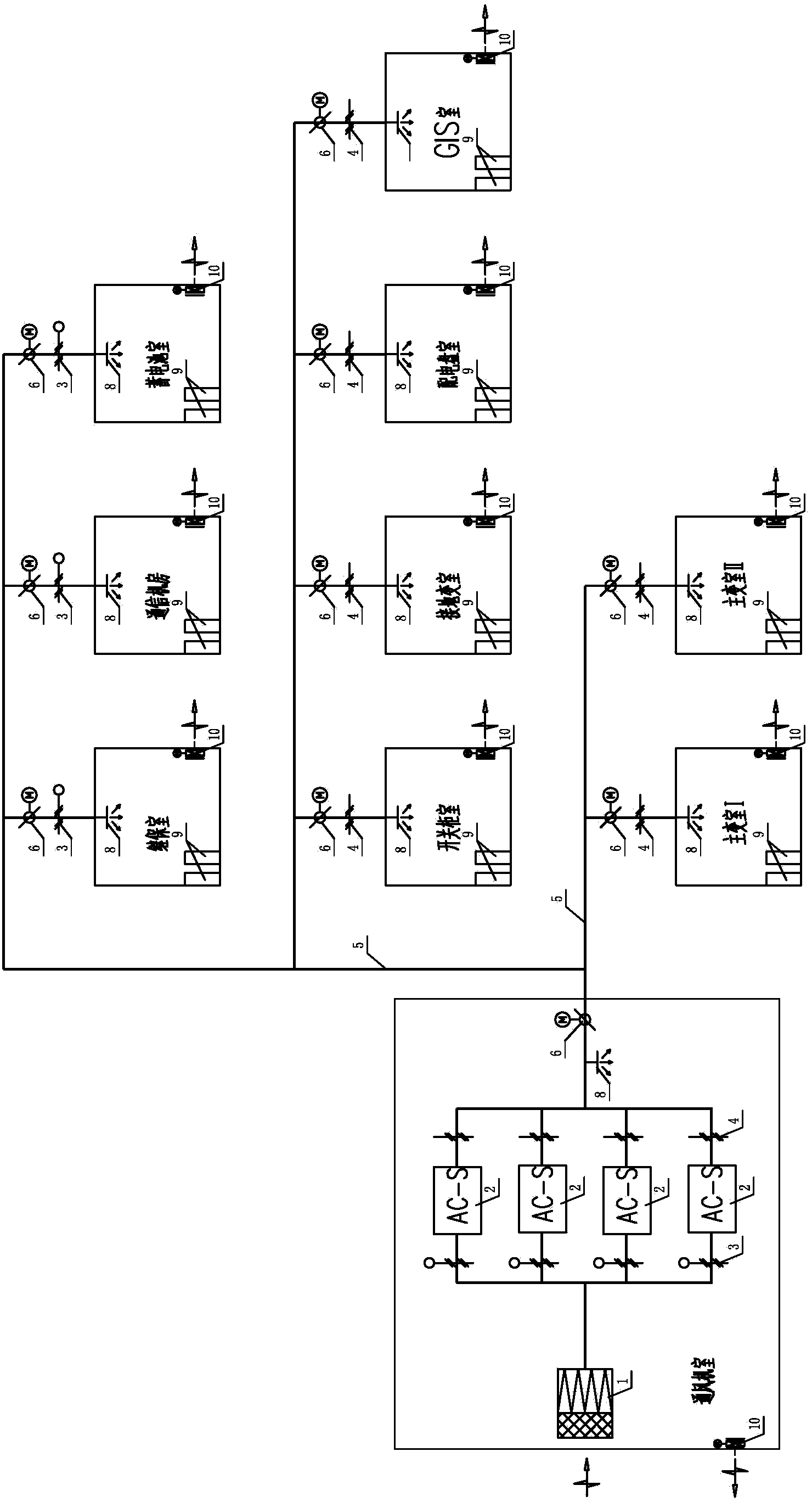

Positive-pressure ventilation system used for seaborne booster station

ActiveCN104390291AReduce salt contentLow ventilation resistanceLighting and heating apparatusSpace heating and ventilation detailsPositive pressureEngineering

The invention relates to a positive-pressure ventilation system used for a seaborne booster station. The invention aims to provide the positive-pressure ventilation system used for the seaborne booster station; electric equipment is prevented from being exposed in a corrosive environment on the basis of guaranteeing effective ventilation and heat radiation, the electric equipment does not lose efficiency due to corrosion, and the seaborne booster station can be operated normally for a long time. According to the technical scheme, the positive-pressure ventilation system is composed of a salt mist removing system, a ventilation pipeline system, room pressure leaking devices, room air conditioning systems and monitoring systems, wherein the salt mist removing system is communicated with each equipment room by the ventilation pipeline system; each equipment room is internally provided with one room pressure leaking device, one room air conditioning system and one monitoring system; the salt mist removing system is used for introducing filtered air into each closed equipment room of the seaborne booster station by the ventilation pipeline system so that air pressure in each equipment room is improved; each room pressure leaking device is used for discharging air in the corresponding equipment room so that the positive pressure being 30Pa-50Pa is maintained in the room relative to the outdoor. The positive-pressure ventilation system used for the seaborne booster station is applied to the field of seaborne wind power generation.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

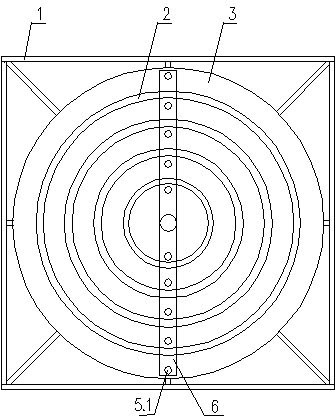

Self-cleaning filter for cigarette factories

ActiveCN102580410AIncrease profitIncrease the filter cross sectionDispersed particle filtrationLighting and heating apparatusFiberHalf-axial

The invention relates to a self-cleaning filter for cigarette factories. Transverse U-shaped section filter rings are concentrically sleeved to obtain the self-cleaning filter, one side of the U shape is provided with a filter screen, and the opening of the other side of the U shape has an inclined plane when the opening is opened; the filter screen is a coated filter obtained by coating a high-molecular porous film on at least one surface of a fiber compacted filter; and two diameter ends of each of the filter rings are respectively provided with a rotary dust absorption deashing nozzle stretching into each of the filter rings, and long hollow suction rods and short hollow suction rods undertake half axial dust absorption of the filter rings respectively. The inclined planes of the filter rings and adjacent straight filter planes form a tapered air out channel, the filter rings can be closely and adjacently arranged without separately setting an air outlet channel aside, and one filter ring can be added on the basis of a double-sided filter ring with a same section, so the filter area is increased by about 20%; and one surface is an inclined plane when opening, so an air inlet is expanded, the air inlet section is increased, and the total air inlet section accounts for 25% of a largest ring area, thereby large air flow filter requirements are satisfied, and the relation between the air inlet area and the filter rings is balanced. Dusts cannot enter the coated film, and the coated film cannot be adhered by wet and viscous dusts, so the dust absorption deashing is thorough, the filter resistance decreases to 80Pa, and the service life of the filter is prolonged.

Owner:无锡市天兴净化空调设备有限公司

Device for treating rice washing waste water

InactiveCN107915347AEasy to recycleEfficient removalTreatment involving filtrationMultistage water/sewage treatmentFlocculationFiltration

The invention discloses a treatment device for rice washing wastewater, which comprises a filter device, a flocculation device and a bubble separation device. net, the bubble separation device includes a bubble generator and a bubble separation chamber, and the flocculation device includes a flocculation chamber and a filter chamber. Through the treatment device for rice washing wastewater of the present invention, the purpose of purifying and treating the rice washing wastewater is achieved.

Owner:CHENGDU WENDA MAOYUAN TECH

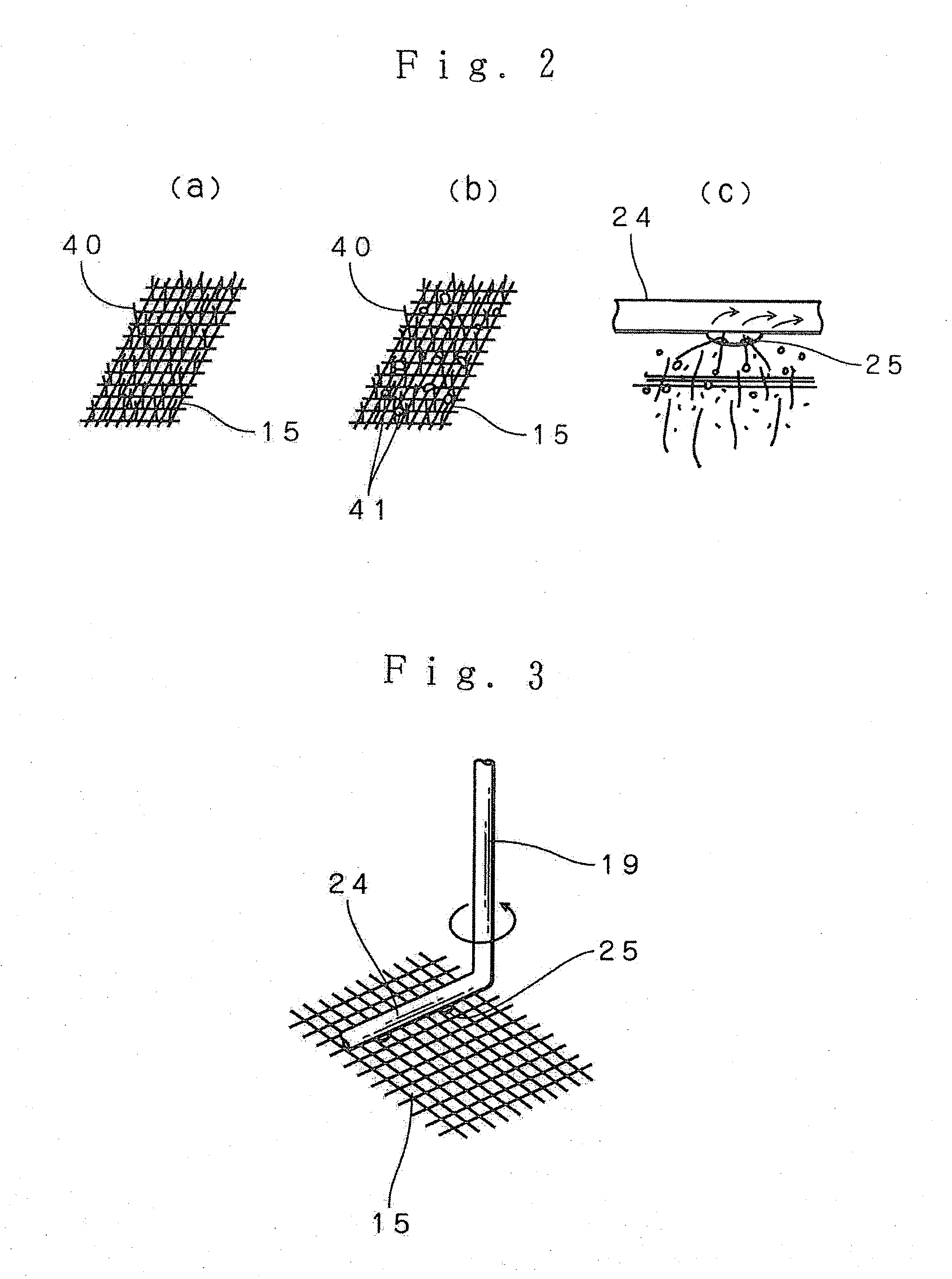

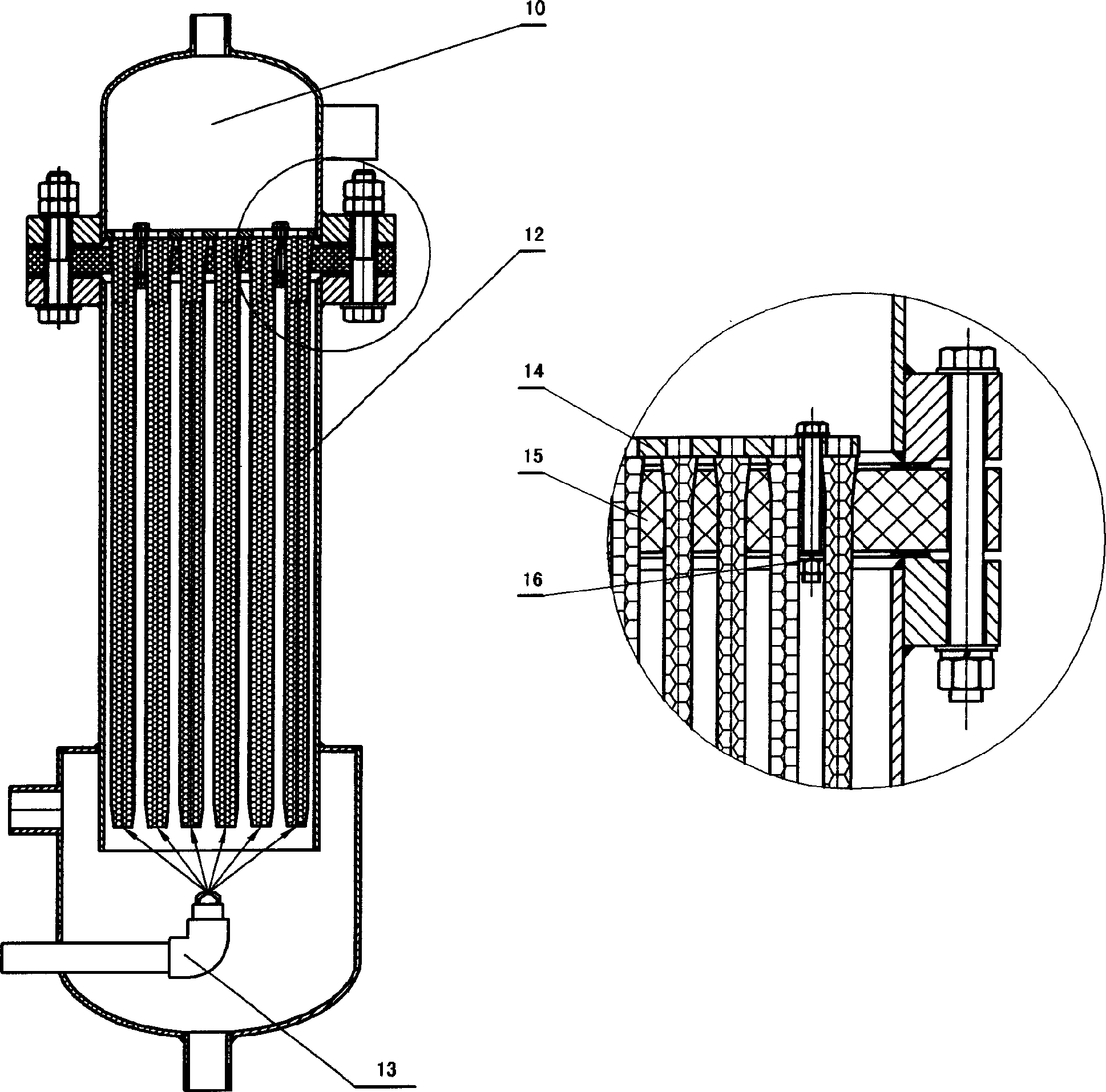

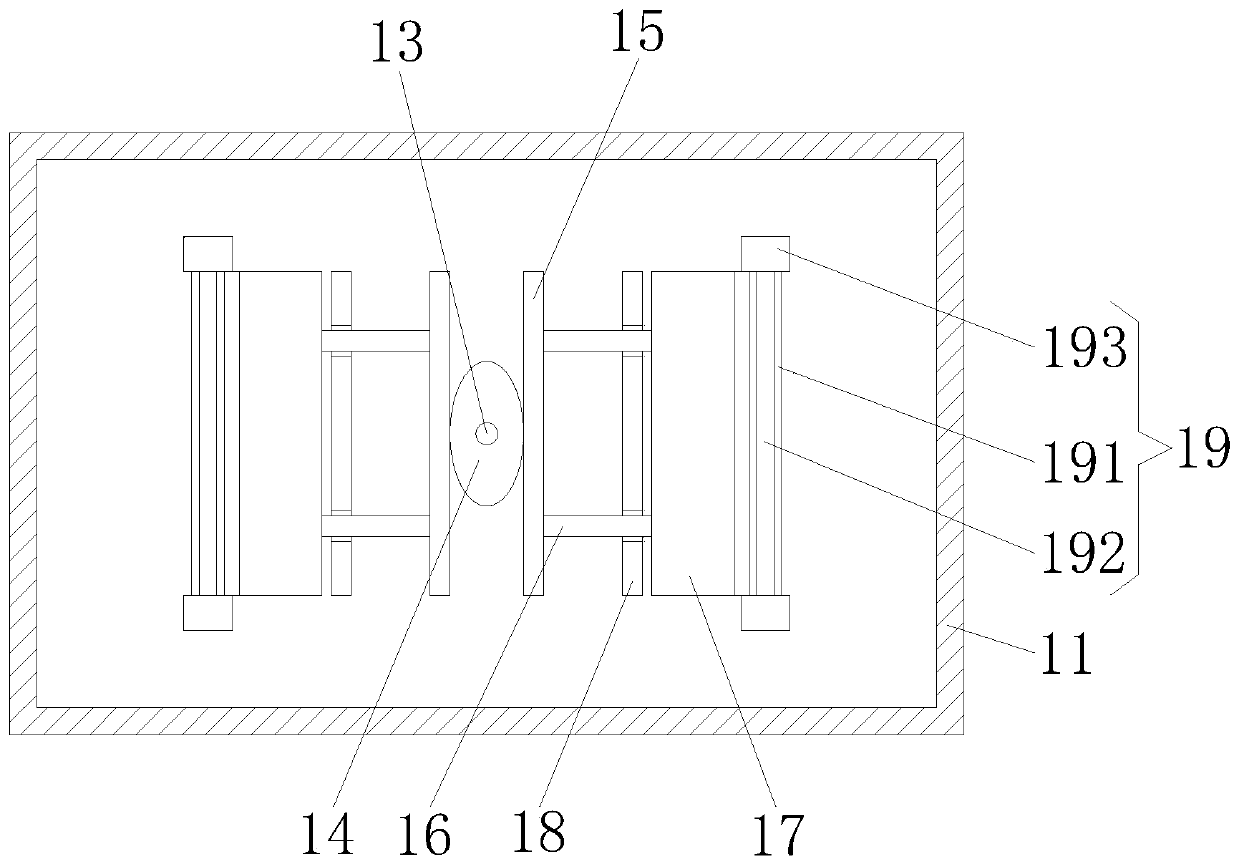

Slow filtration device having excellent ability to treat microorganisms

InactiveUS20110278213A1Fast formingStart fastSpecific water treatment objectivesTreatment involving filtrationMicroorganismFiltration

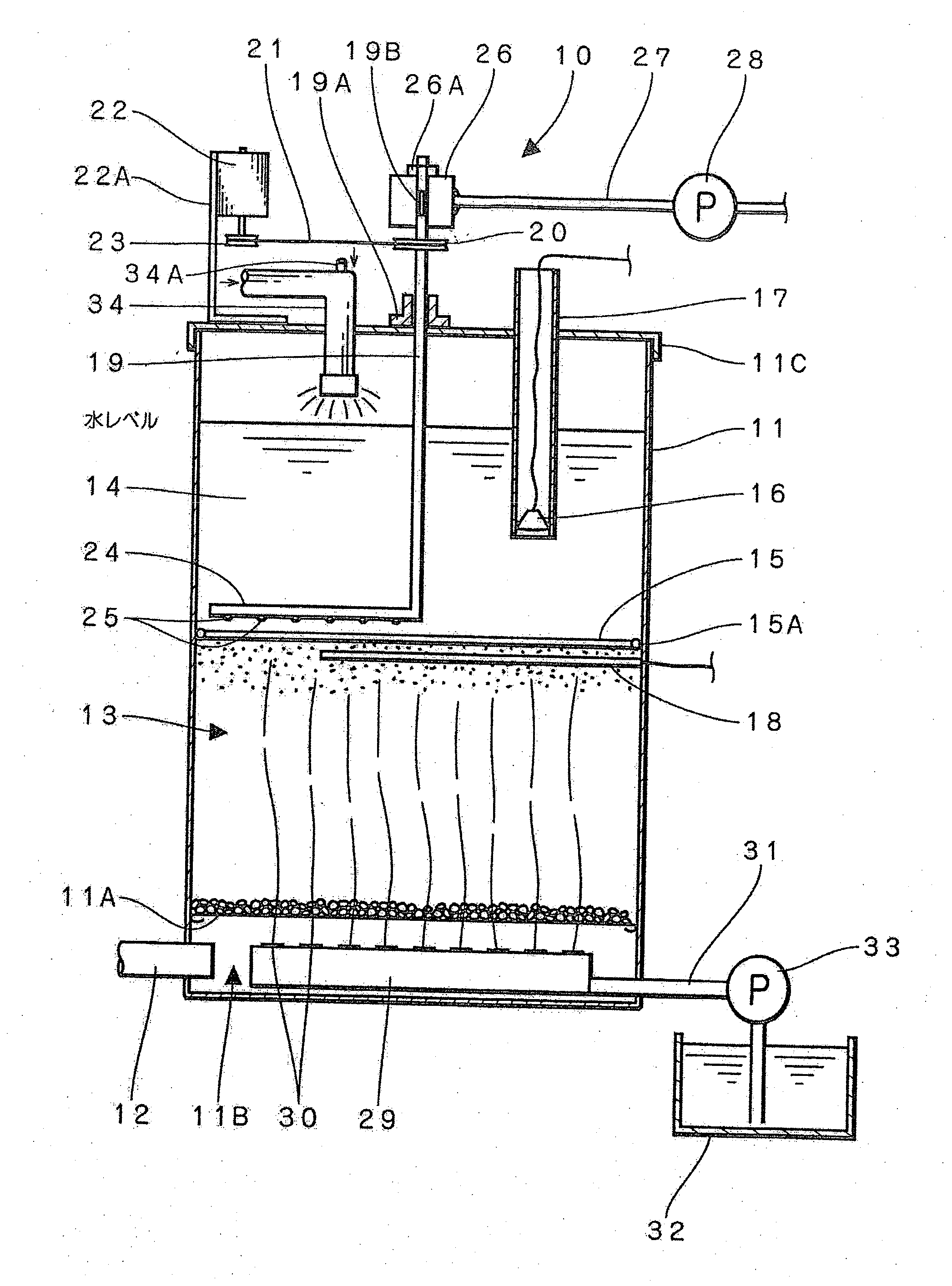

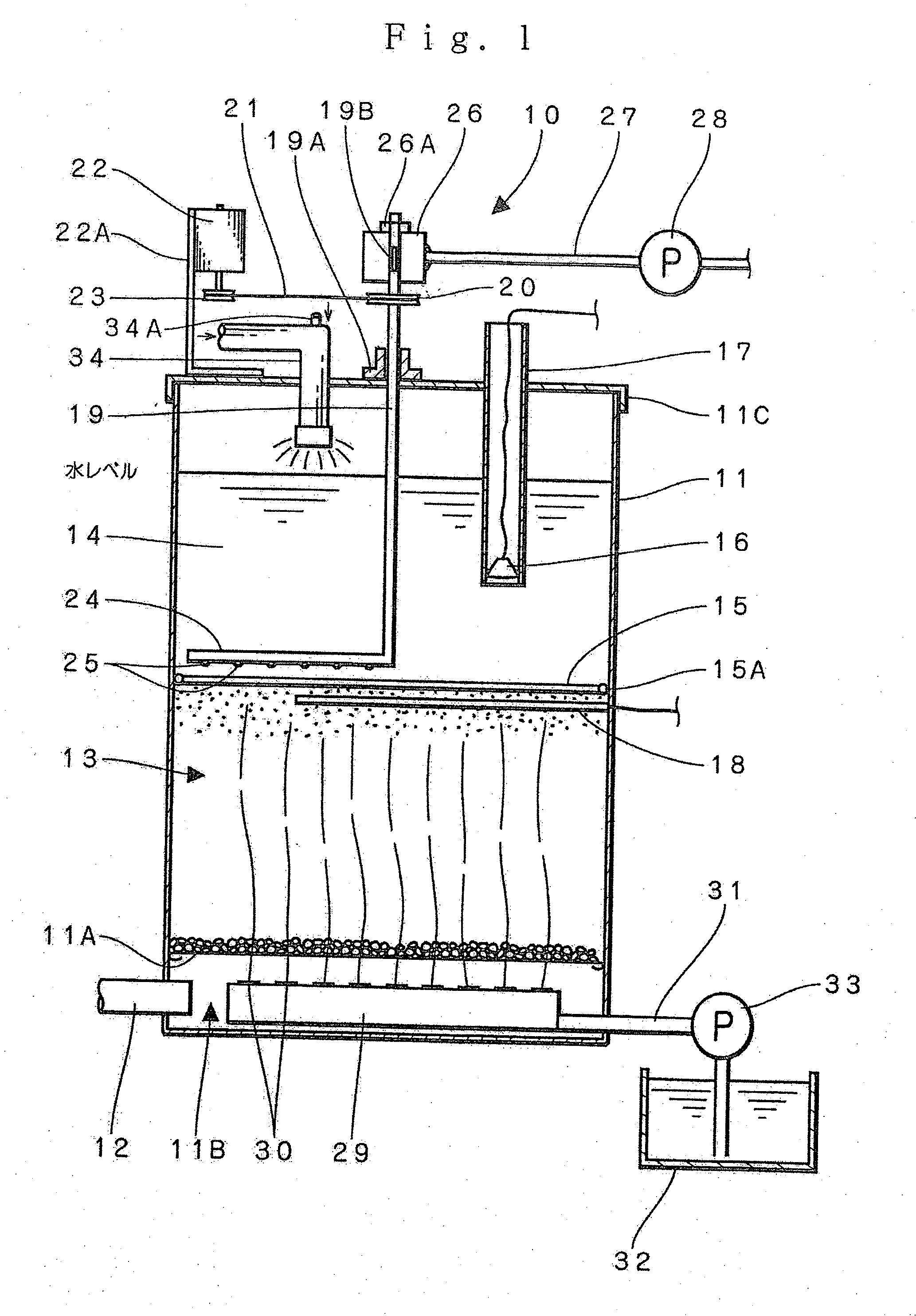

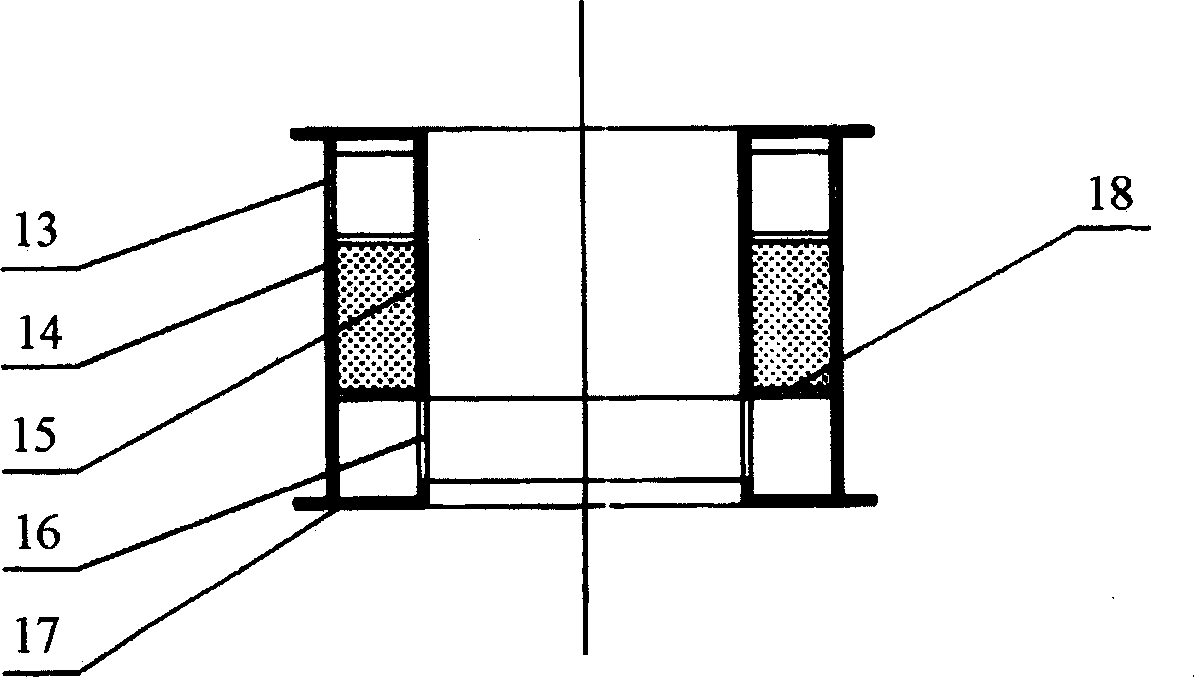

There is provided a slow filtration device adapted so that raw water sampled from a river or out of the ground can be treated into drinkable water, etc. in a short time after being newly assembled. The slow filtration device including a filtration sand layer, a raw-water supply part, and a removal part includes a net (15) provided above a filtration sand layer (13) within the filtration tank (11) so as to cover the filtration sand layer (13) and used as a carrier for the breeding of algae, a heat-generating heater (18) provided directly below the net (15) to maintain the net (15) at a predetermined temperature, and an algae raising lamp (16) provided above the net (15) within the filtration tank (11) to radiate light onto the net (15) and promote growth of the algae.

Owner:MIYAZAKI TOYOFUMI

Dense solid-liquid separation method in wet zinc smelting solution capable of improving clarification effect

ActiveCN104674024AGood clarificationIncrease production capacityProcess efficiency improvementGranularitySlurry

The invention discloses a dense solid-liquid separation method in a wet zinc smelting solution capable of improving the clarification effect, and belongs to the technical field of wet zinc smelting. According to the dense solid-liquid separation method in a wet zinc smelting solution capable of improving the clarification effect disclosed by the invention, the roasted ore granularity is properly increased, so that the problems that solid-liquid separation and clarification effects of leaching slurry are not good, the speed is slow, the middle and upper clear liquid is small in capacity, mudflow of a thick supernatant is caused, the solid content of the liquid is increased, the quality of the supernatant is worsened, or even a qualified middle and upper clear liquid containing zinc cannot be produced, and the wet production cannot be lastingly carried out are solved. A physical state of roasted ore is optimized; the roasted ore granularity is properly increased; the content of soluble silicon and iron is reduced; the liquid-to-solid ratio of a feed pulp is increased; the temperature of the pulp is improved; and the dense clarification effect is improved by a combined step of optimizing the operation method of a flocculant and changing the adding point of 3# polyacrylamide.

Owner:BAIYIN NONFERROUS GROUP

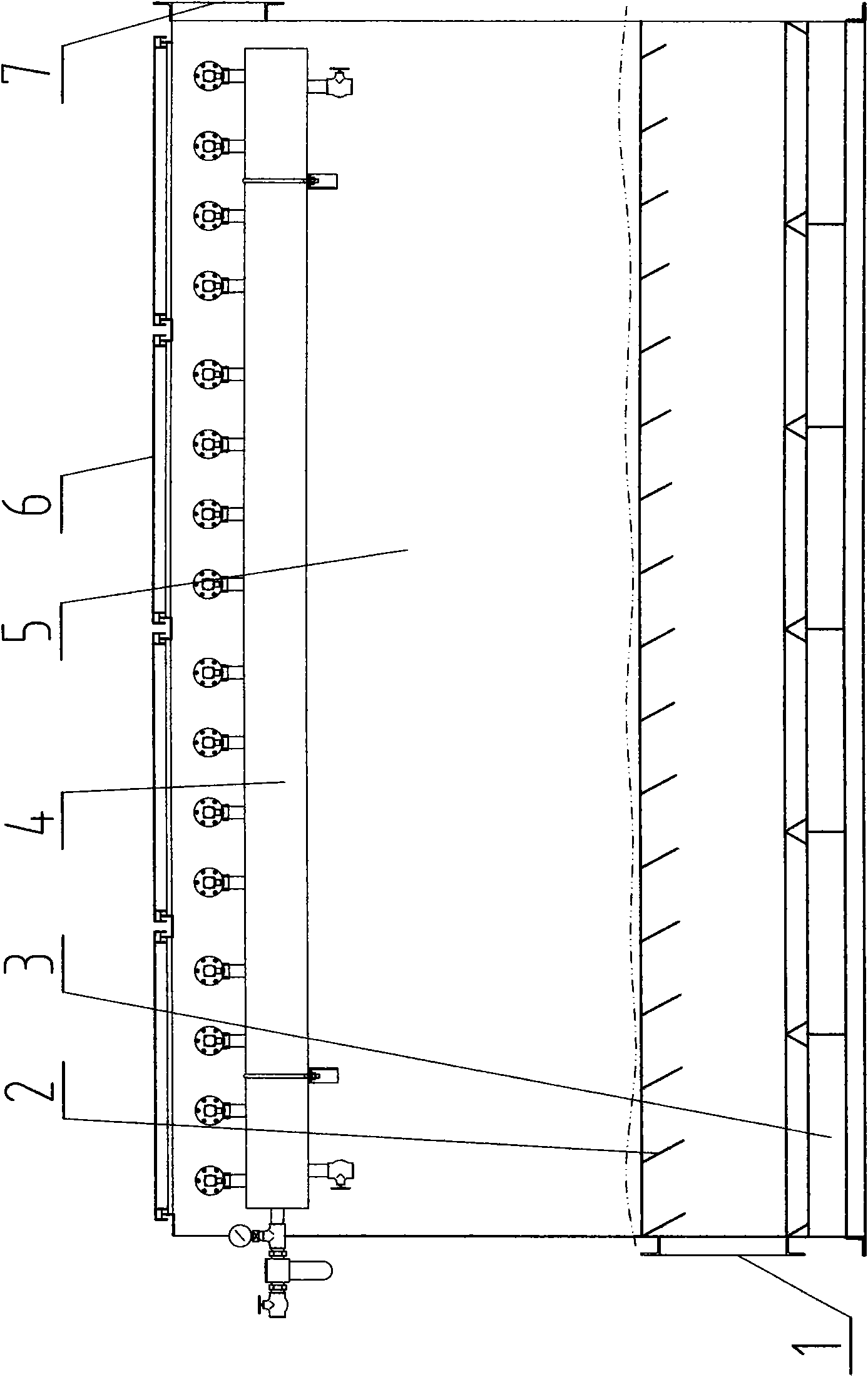

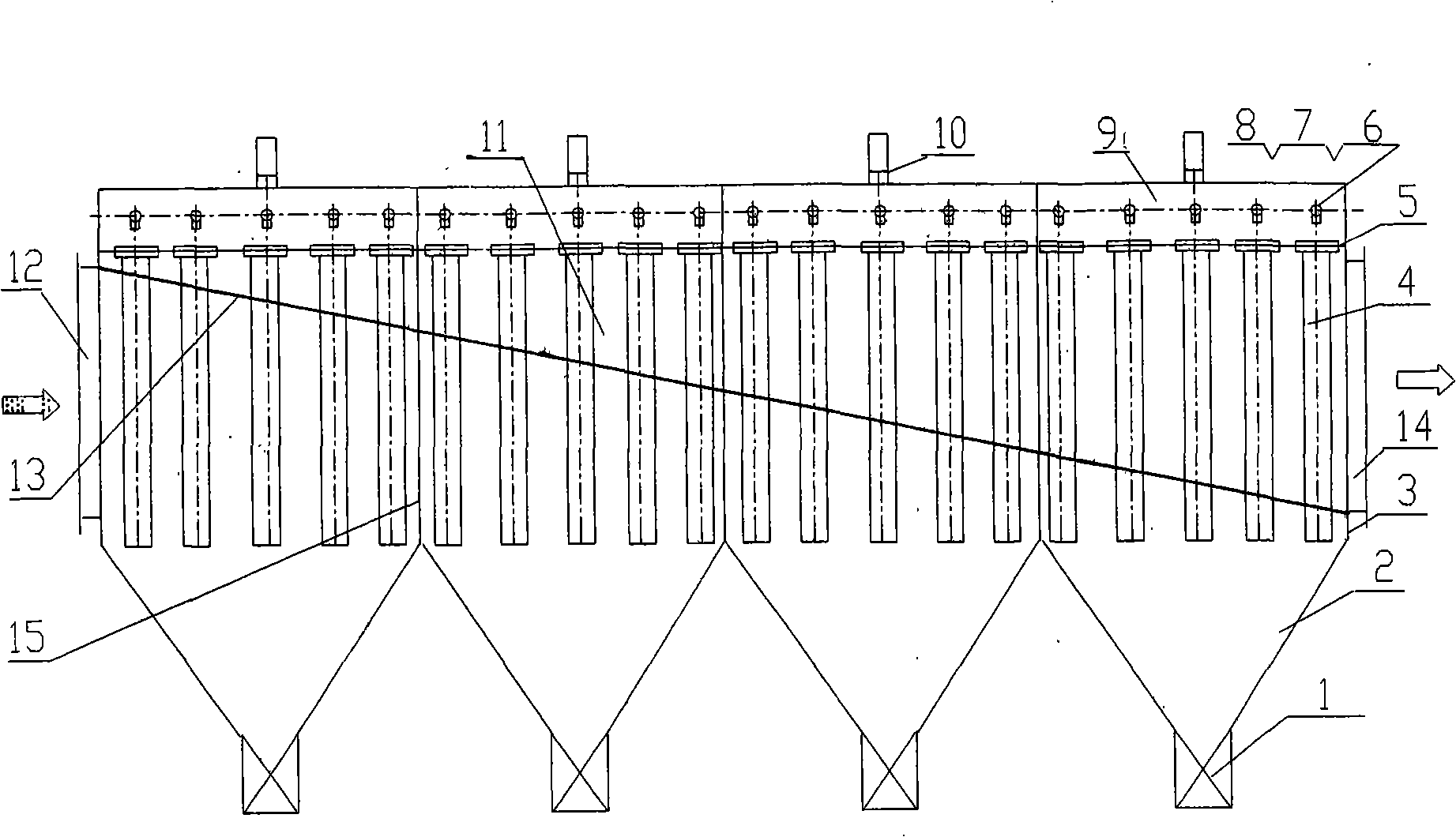

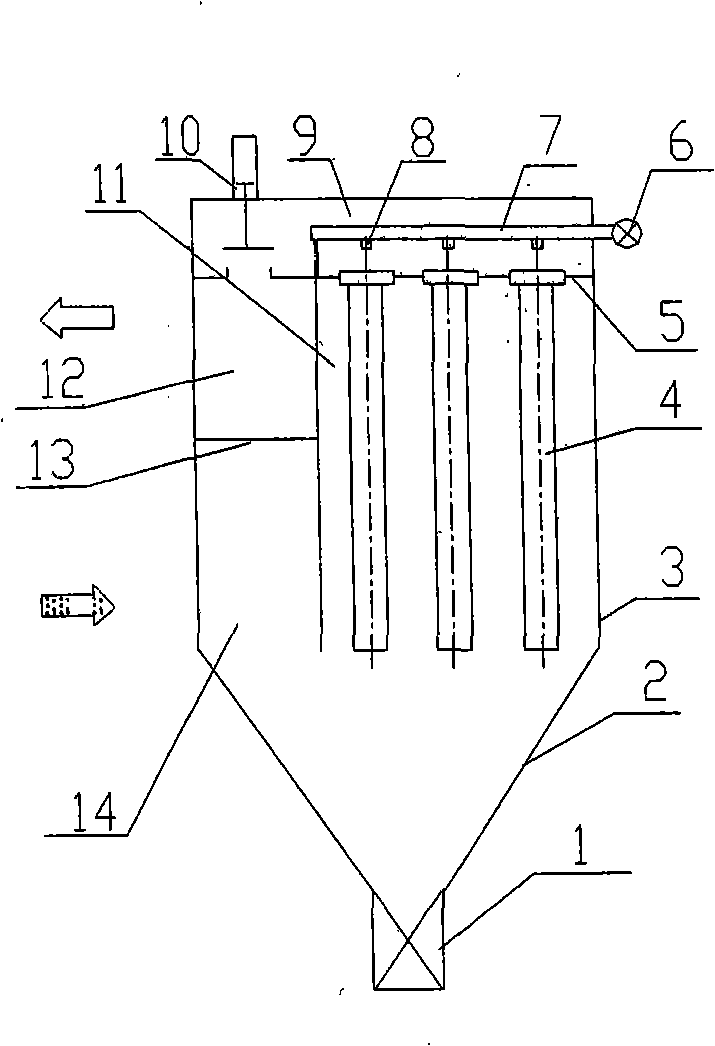

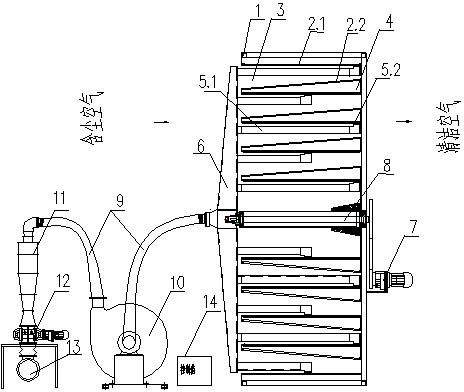

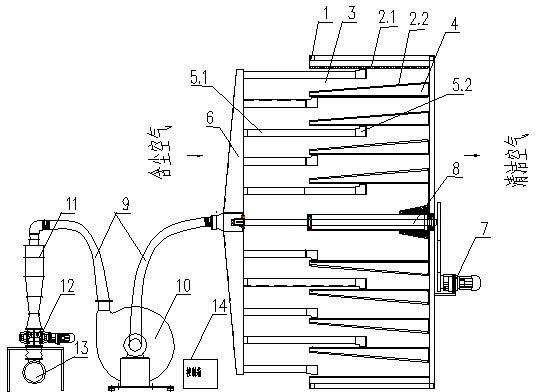

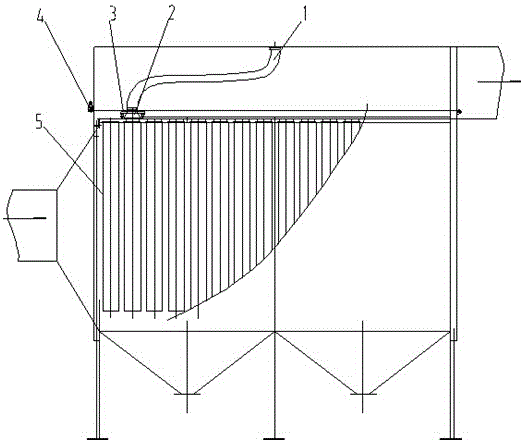

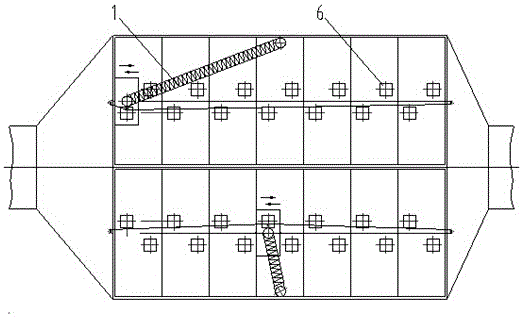

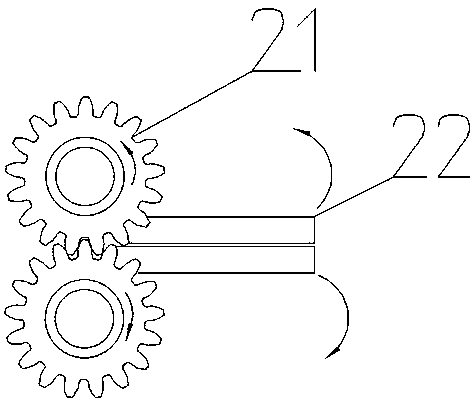

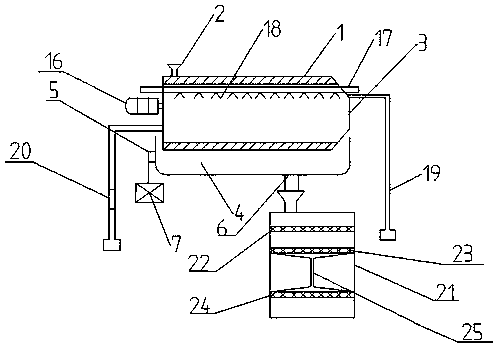

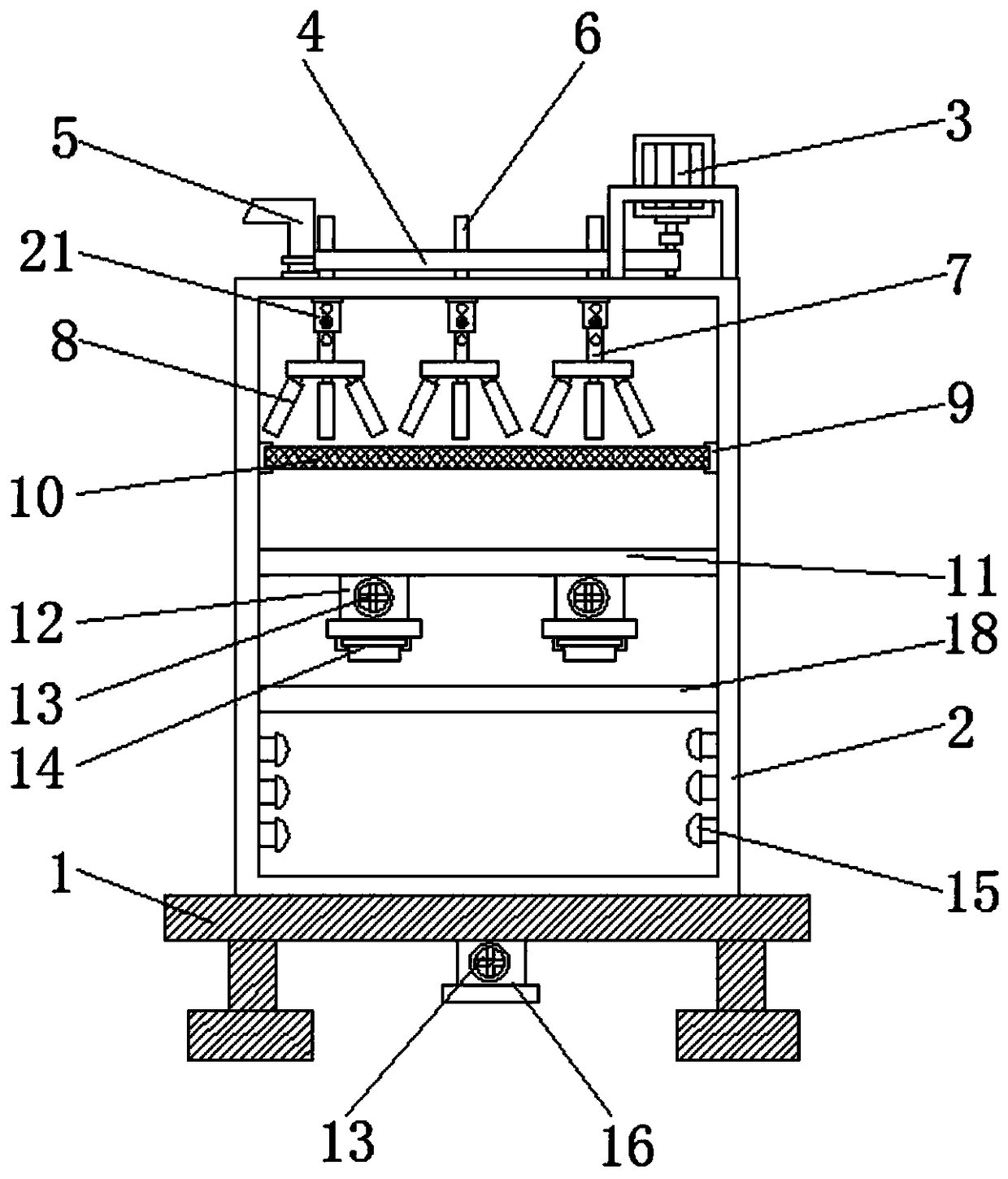

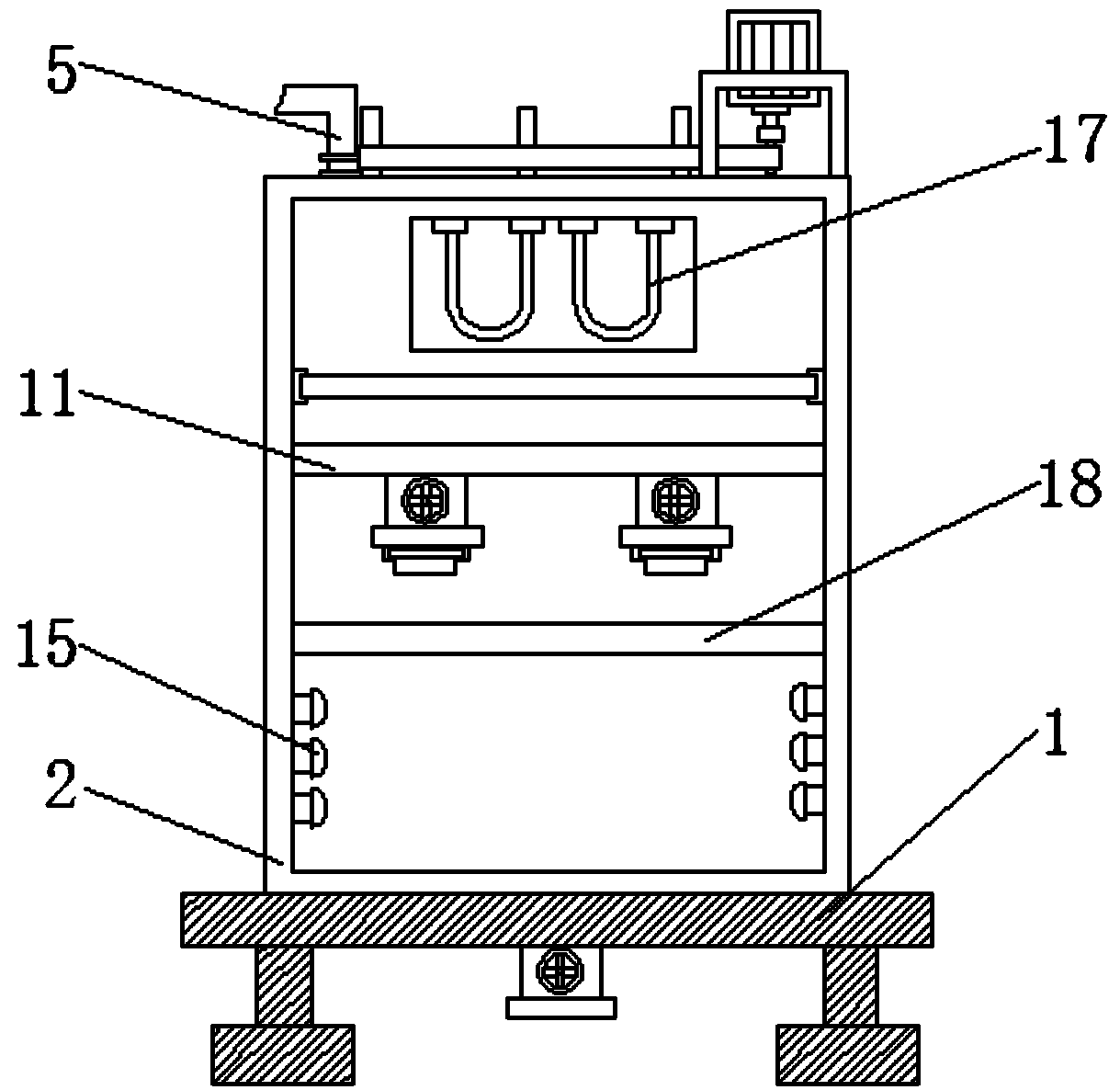

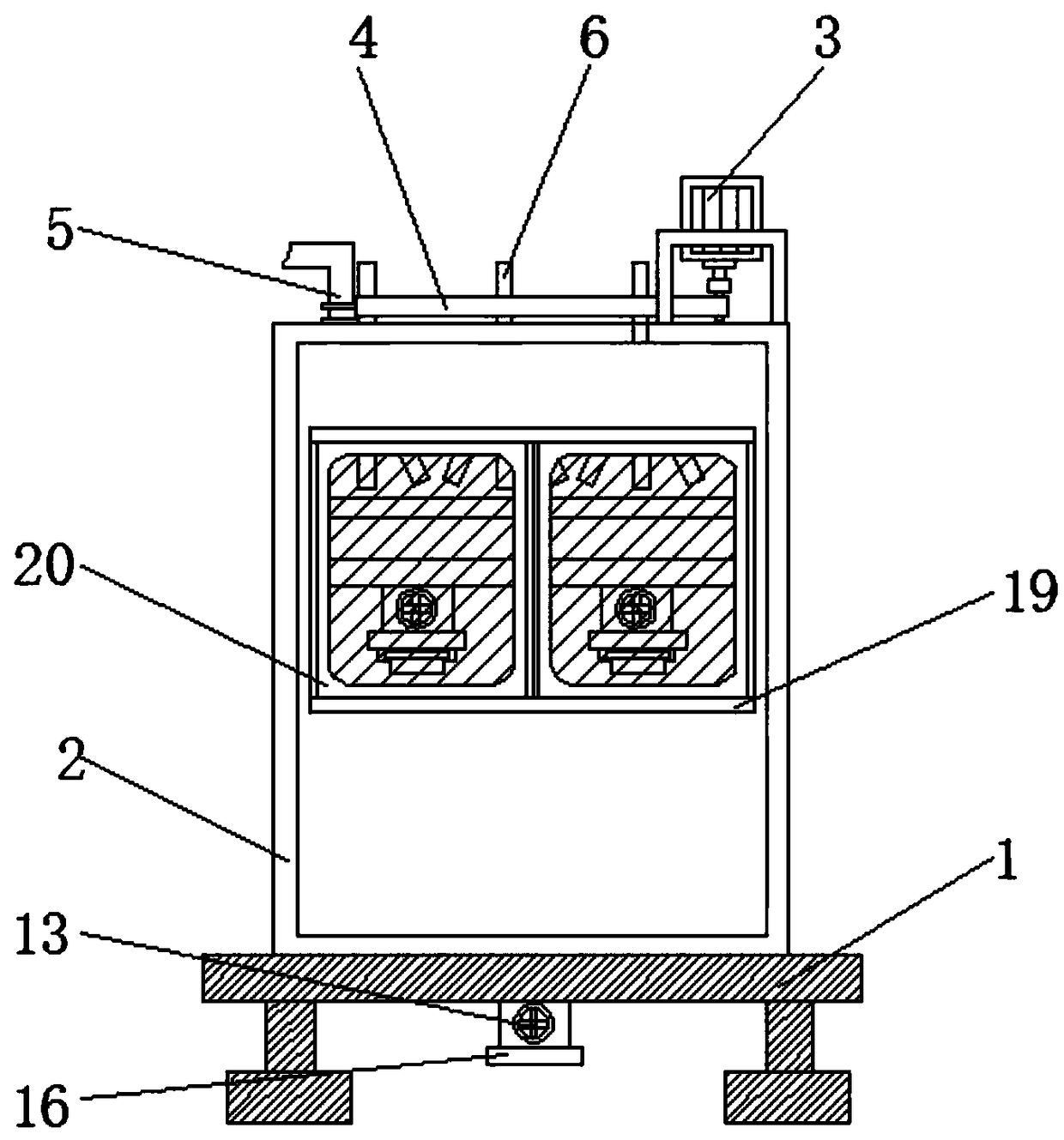

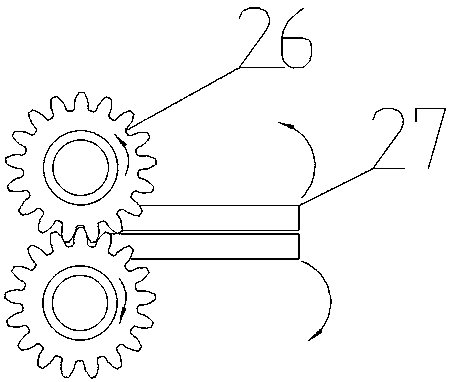

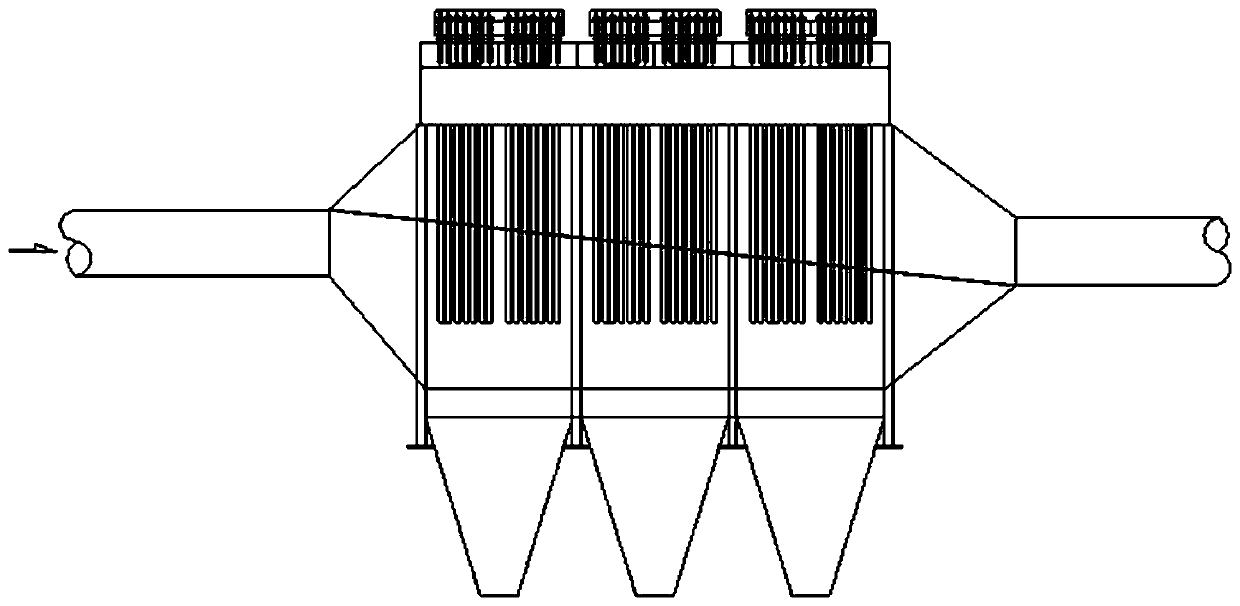

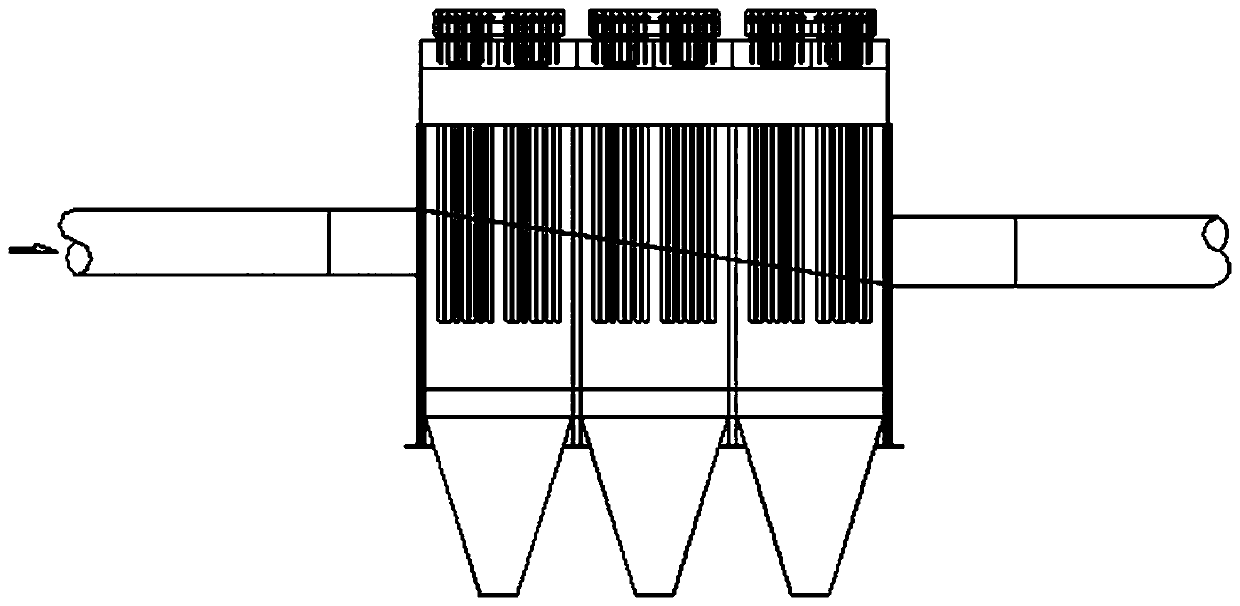

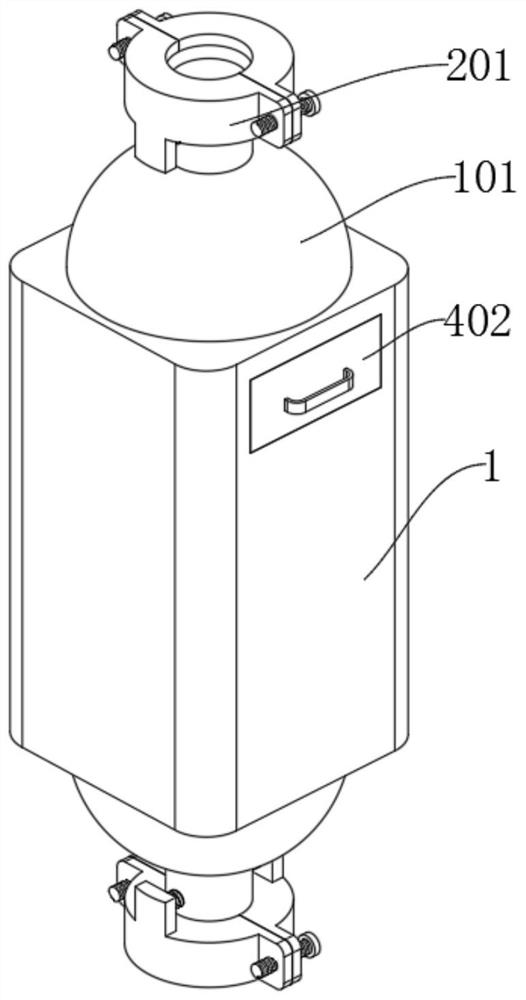

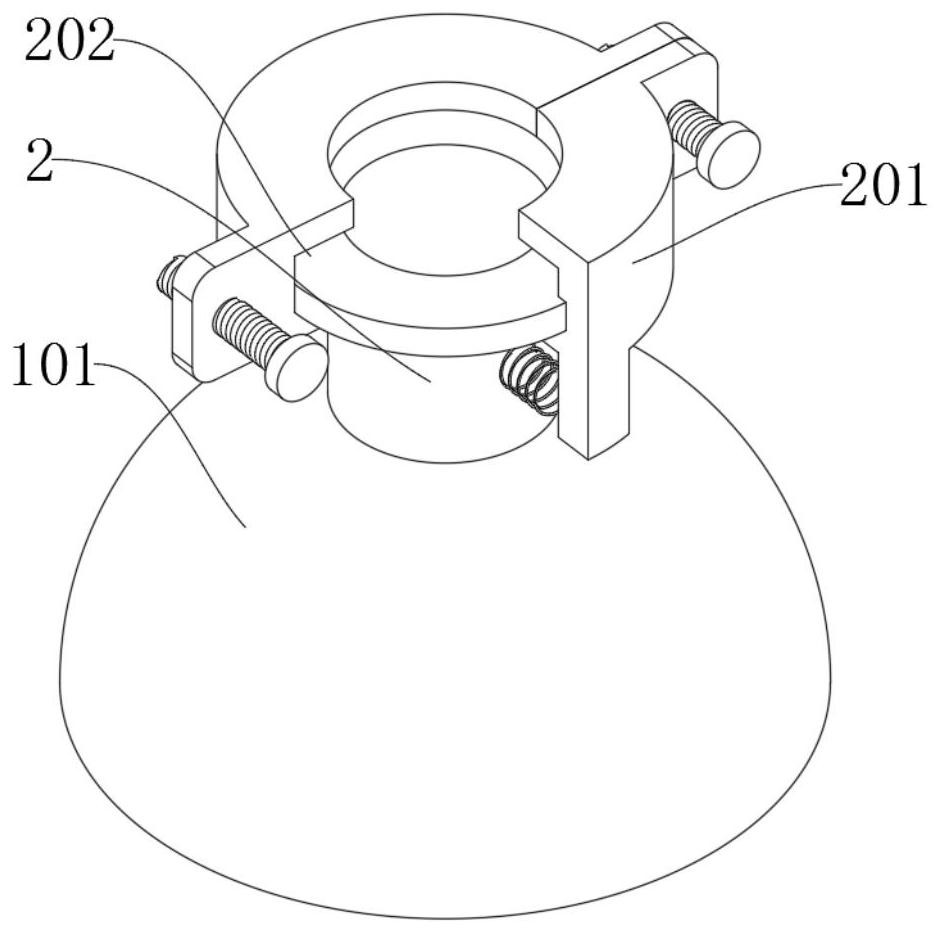

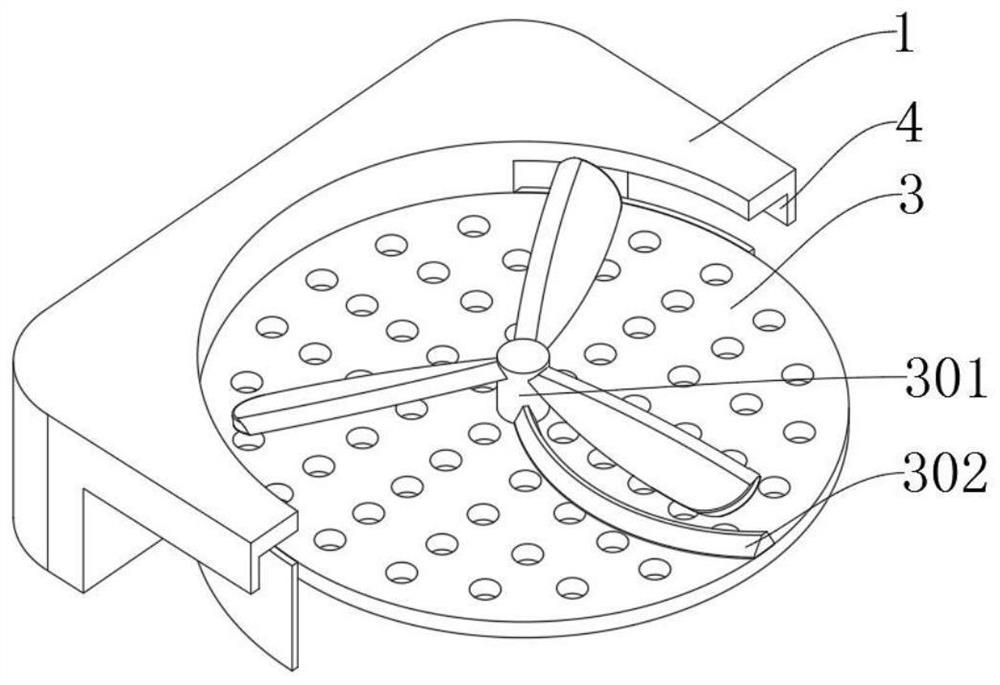

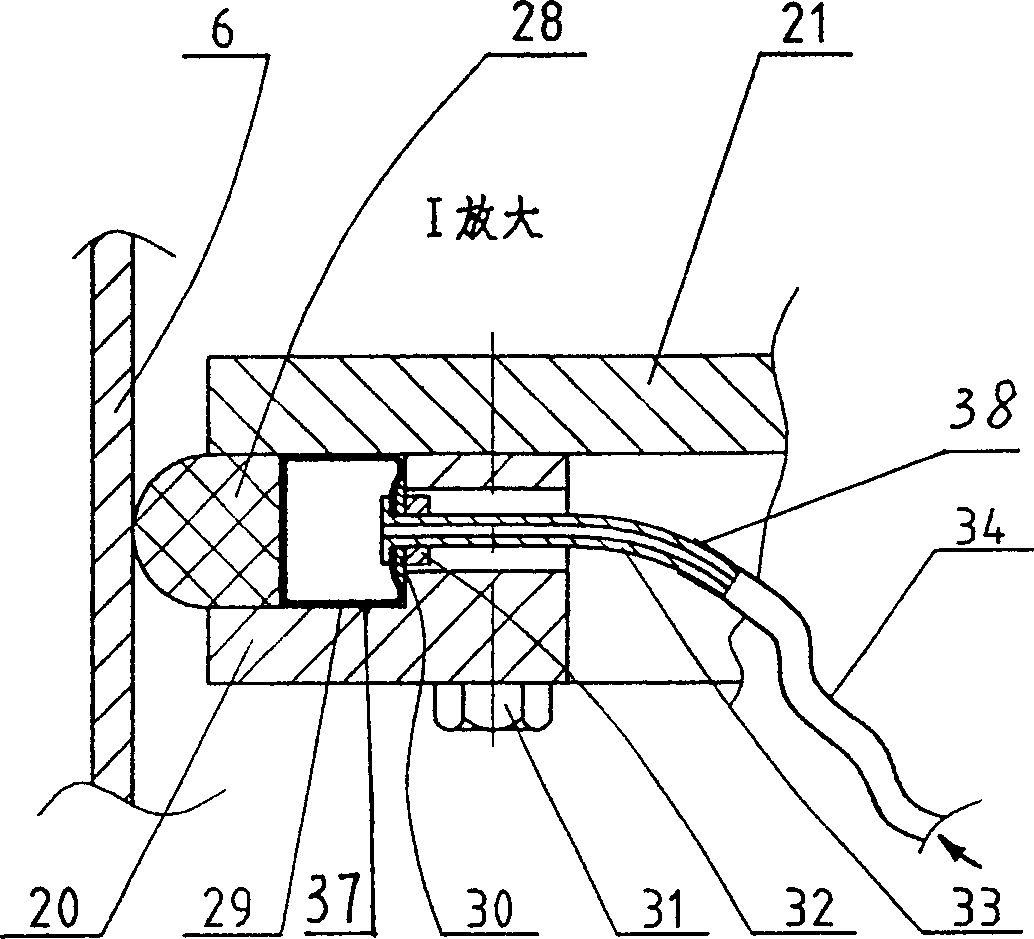

Closed cloth-bag-type low-pressure ash-removing dust remover

InactiveCN105854445AReduce volumeReduce filter speedHuman health protectionDispersed particle filtrationReducerModular structure

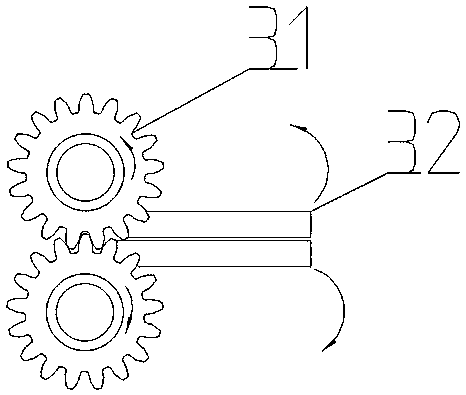

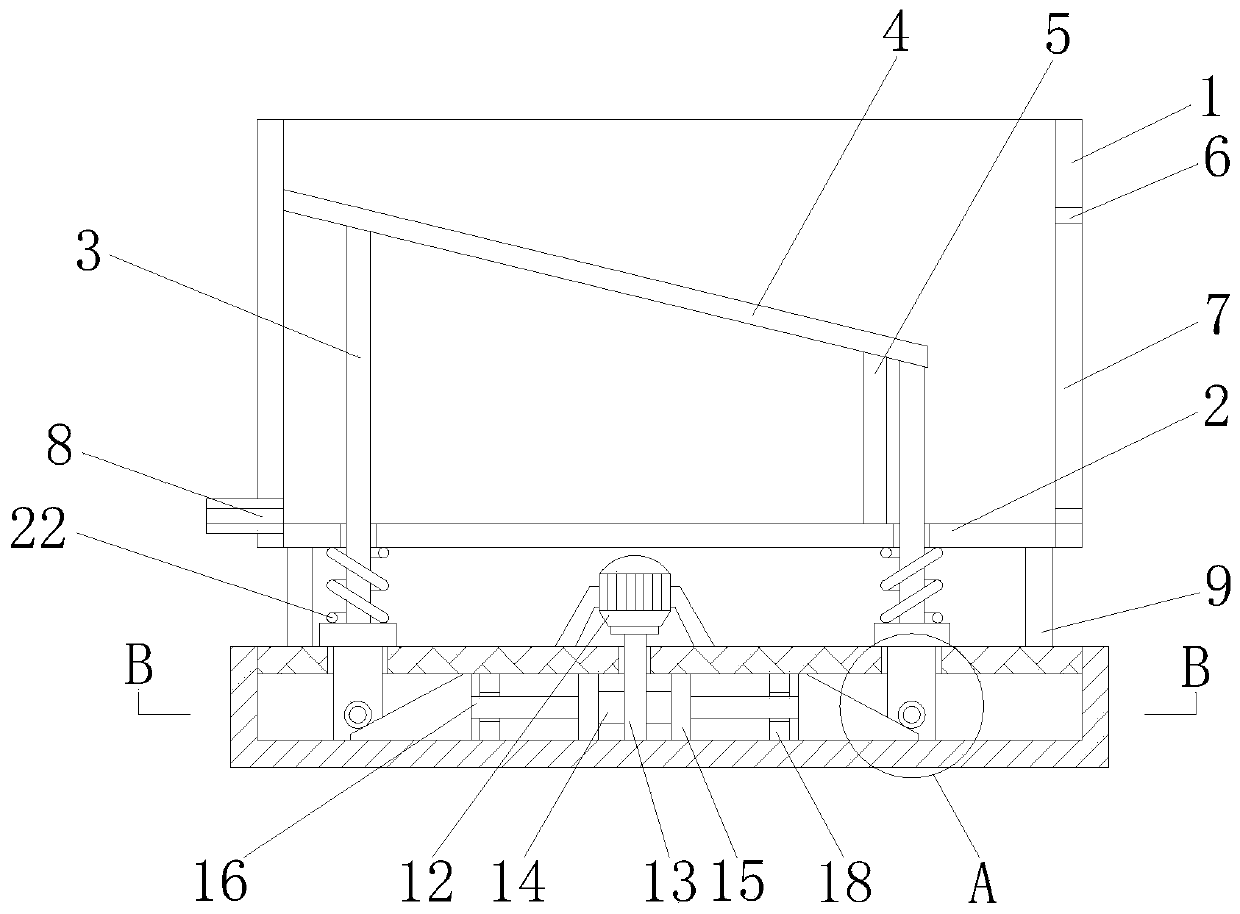

The invention discloses a closed cloth-bag-type low-pressure ash-removing dust remover, and relates to an industrial dust remover. The dust remover comprises a flexible pipe (1), an ash removing cover (2), a trolley (3), a reducer (4), filtering bags (5) and air purifying chambers (6). A dust-remover purifying sub-chamber in a dust-remover ash-removing device is of a modular structure, the air purifying chambers are divided into a plurality of closed units, an outlet of a boiler induced-draft fan is connected to one end of a dust-remover cylinder, and the dust-remover cylinder is horizontally supported on a support; an ash removing system is connected to a motor and the reducer through a chain, and is connected with the ash removing cover and the trolley, and the ash removing cover and the trolley are arranged in the arraying direction ofan inlet and an outlet, and are located on a rail in a straight-line-reciprocating-moving-type mode; the filtering bags are hung to a ceiling in line and in row, and are supported through bag cages; low-pressure air generated by the outlet of the boiler induced-draft fan or other low-pressure air is subjected to converse purging through the dust remover, the closing aim and the leak-free aim are achieved, the spraying-blowing effect is guaranteed, the filtering bags are not damaged, materials are saved, and the service life of a machine is prolonged.

Owner:沈阳朗立电力设备有限公司

Rice-washing wastewater treatment equipment

InactiveCN107840478AEnough settling timeGuaranteed Filtration EfficiencyTreatment involving filtrationMultistage water/sewage treatmentFiltrationWater treatment

The invention discloses rice washing wastewater treatment equipment, which comprises a filter device and a separation device. The filter device includes a filter tank, a filter net is arranged in the filter tank, and a waste water inlet and a waste water outlet are arranged in the filter tank. The waste water outlet is connected to a separation device, the separation device includes a separation chamber, a sleeve is arranged in the separation chamber, a rotating device is arranged inside the sleeve, two air inlet pipes are connected to the sleeve, and the air inlet pipe and The sleeve communicates internally. Through the rice washing wastewater treatment equipment of the present invention, the rice washing wastewater is subjected to multi-stage filtration and treatment, and the rotation of the rotating device generates air bubbles, thereby efficiently purifying the rice washing wastewater.

Owner:CHENGDU WENDA MAOYUAN TECH

Sticky rice washing device with function of rice washing water treatment

InactiveCN107754973AEnough settling timeGuaranteed Filtration EfficiencySievingScreeningFiltrationWastewater

The invention discloses a sticky rice washing device with the function of rice washing water treatment. The sticky rice washing device comprises a washing device and a waste water treatment device. The washing device comprises a rotating barrel. The rotating barrel is arranged transversely and is provided with a feeding opening and a discharging opening. The rotating barrel can be controlled by arotating mechanism to rotate. The waste water treatment device comprises a filter pond. Filter screens are arranged in the filter pond. A waste water inlet is formed in the upper portion of the filterpond, and a waste water outlet is formed in the lower portion of the filter pond.

Owner:CHENGDU WENDA MAOYUAN TECH

High oxidizing filtering system

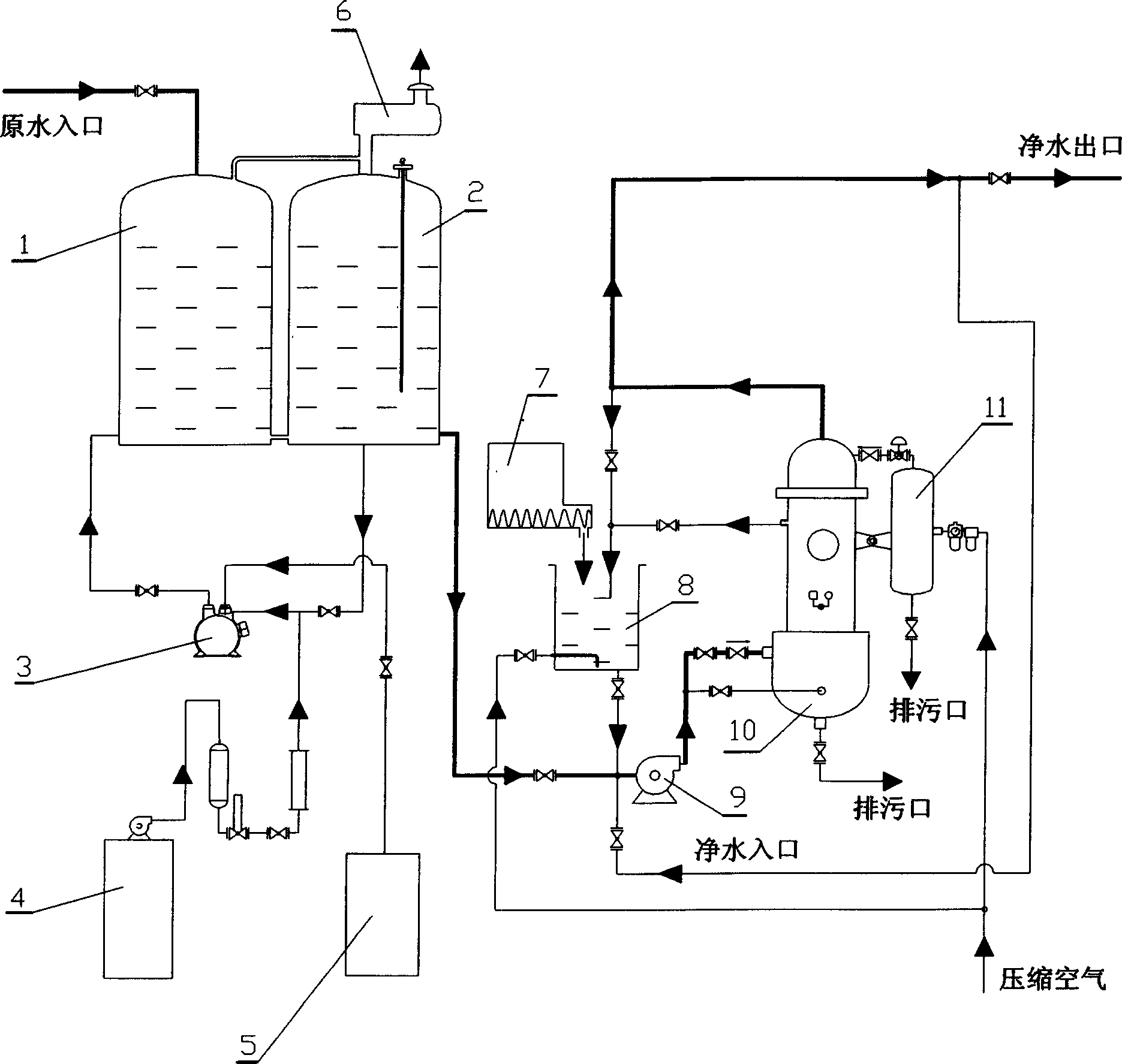

InactiveCN1693237AEconomically superiorInhibition of concentration polarizationMultistage water/sewage treatmentChemistryRiver water

High oxidizing filtering system includes: high oxidizing mixing tank, high oxidizing contacting reaction pitcher, filtering pump, diatomite film filtering tank. The characteristics is that the outlet of the high oxidizing contacting reaction pitcher connects to the inlet of the filtering pump, the outlet of the filtering pump connects to the inlet of the diatomite film filtering tank, the high oxidizing mixed tank connects to the bottom of the high oxidizing contacting reaction pitcher. There are eddy current pump, ozone generator, hydrogen peroxide injection box on the bottom of the oxidizing mixed tank. There are gasholder, diatomite box, diatomite mixing box inner the diatomite film filtering tank. The beneficial effect of this invention is that high oxidizing and diatomite film combine with each other, oxidizing and filtering go along simultaneous, reducing the SS CODcr BOD of the original water as well as flavor, decolorizing, decreasing turbidity, sterilization, the wastewater according to the sullage emission standard can be reused after treatment, the river water pond water as well as ground water can reach drinking water standard after treatment.

Owner:吉林守信环境工程有限公司

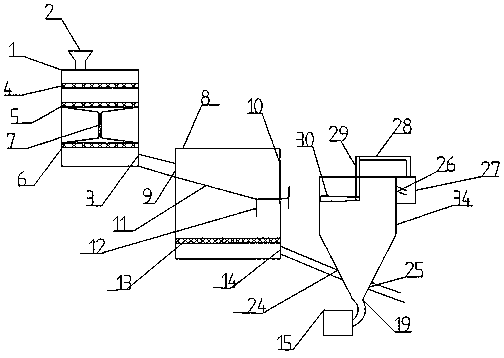

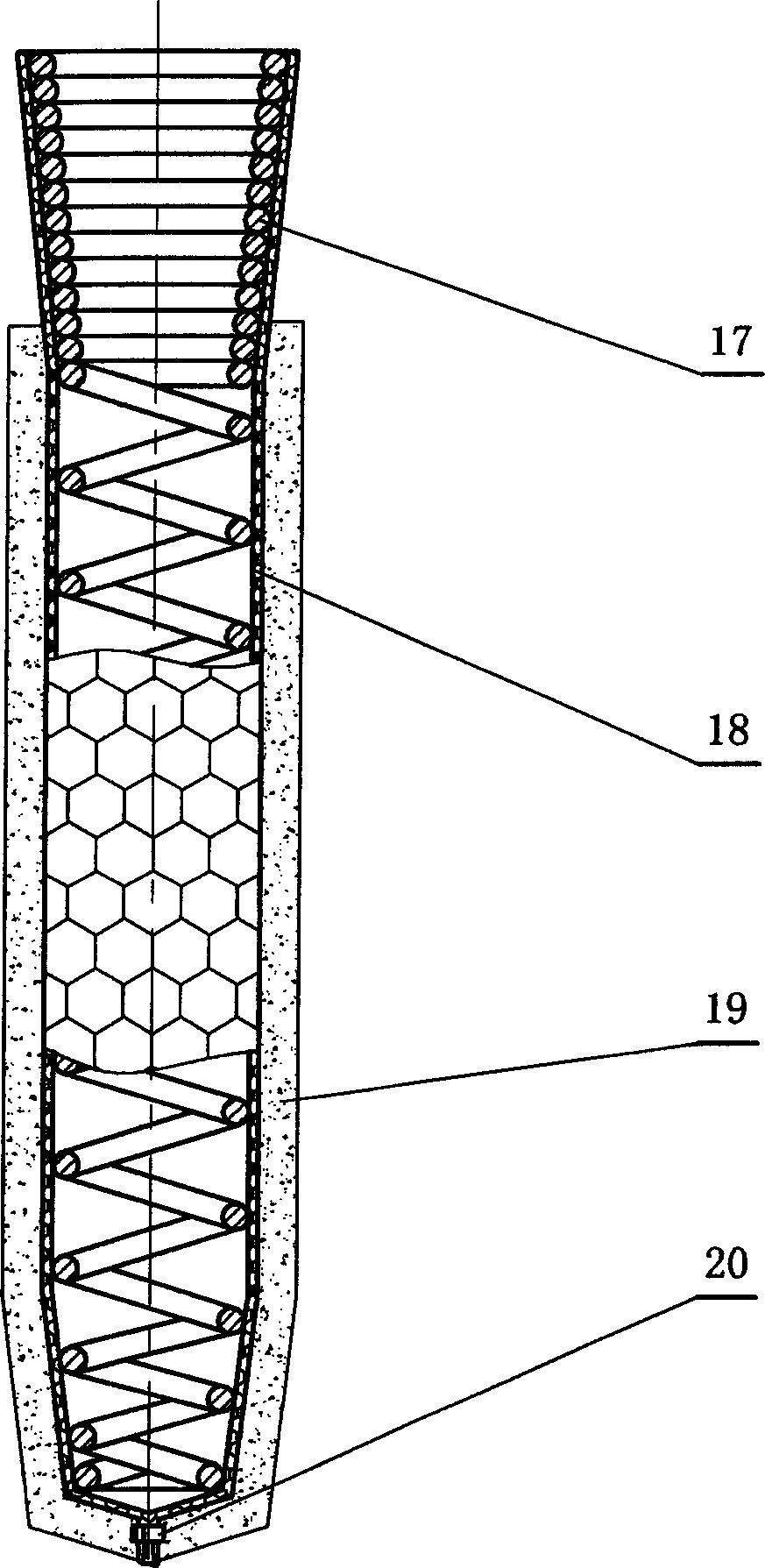

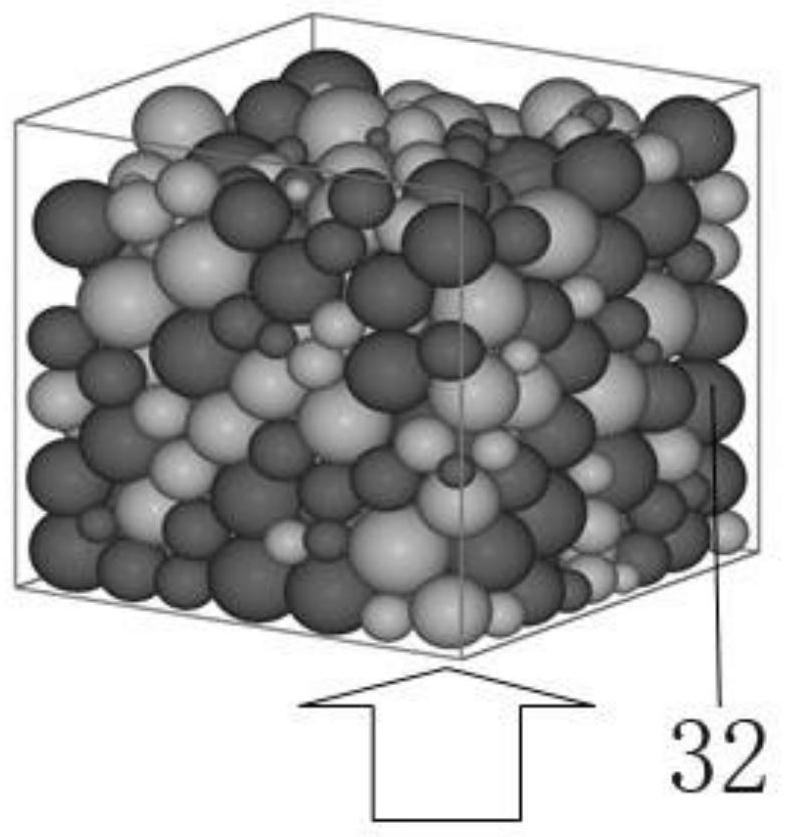

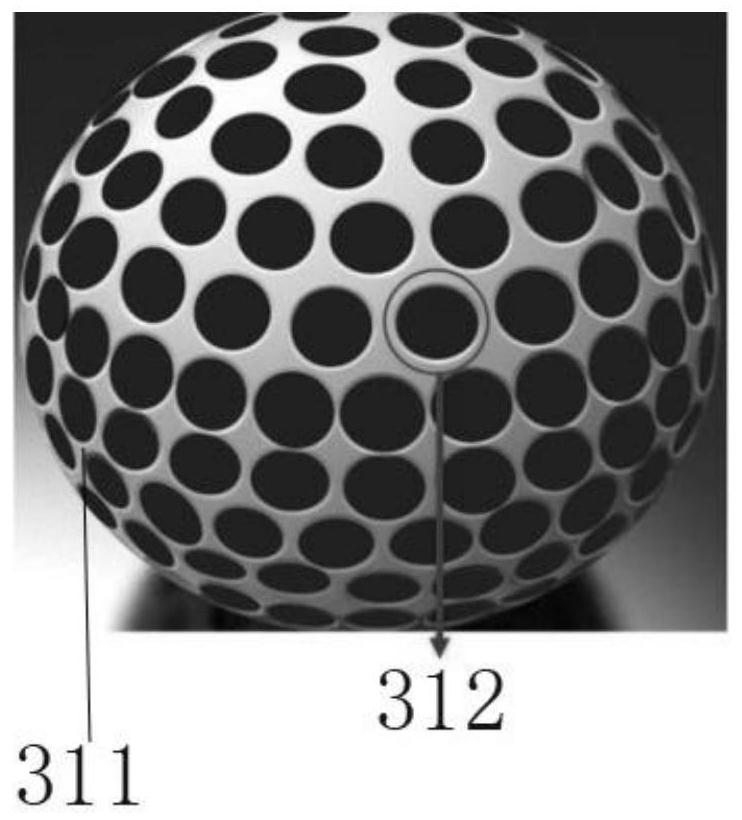

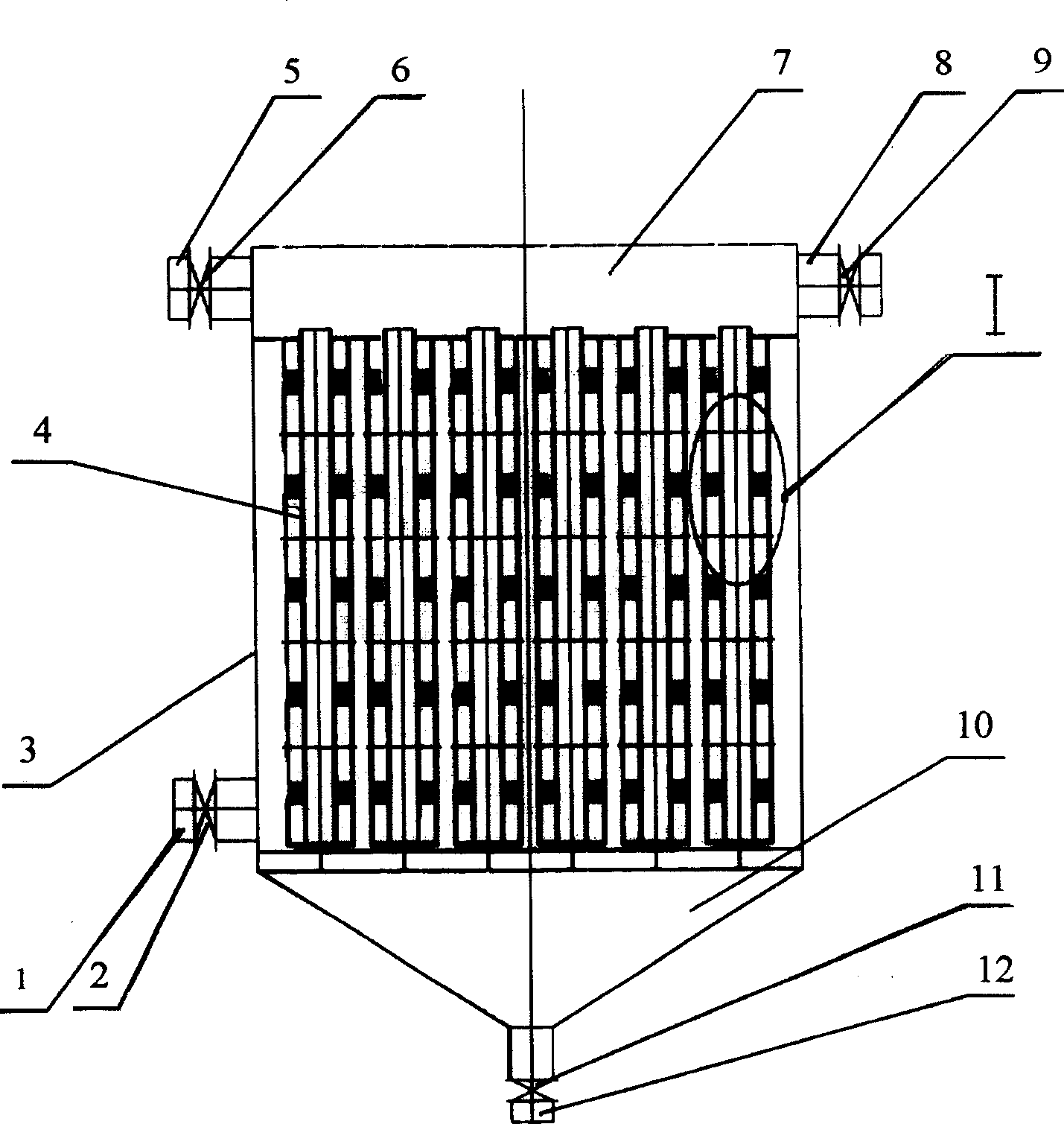

Enhanced coalescence and efficient granular layer filtering device for ultrafine particles

ActiveCN113813732AEasy reunionImprove filtration efficiencyCombination devicesFine particulatePulse power supply

The invention discloses an enhanced coalescence and efficient granular layer filtering device for ultrafine particles, and belongs to the technical field of flue gas purification. The filtering device comprises a pre-charging area, an agglomeration area and a filtering area, the pre-charging area comprises a conductive metal plate I, a ternary rare earth tungsten (W-La2O3-CeO2-Y2O3) barb and a conductive metal plate II; the agglomeration area comprises a primary coagulation area and an alternating electric field coagulation area; and the filtering area is a particle layer formed by porous particle swarms. According to the method, an electrode plate with ternary rare earth tungsten barbs serves as a discharge cathode, high-density free electrons, negative ions and positive ions exist in a whole electric field channel in a nanosecond pulse power supply mode through the diffusion discharge phenomenon, and superfine dust particles are subjected to sufficient and uniform heteropolar charge; secondly, the agglomeration and coagulation of the ultrafine dust particles are strengthened by utilizing the synergistic effect of a turbulent boundary layer, coulomb force and an alternating electric field; and finally, the dust particles are efficiently captured by a particle layer formed by porous particles.

Owner:NANJING NORMAL UNIVERSITY

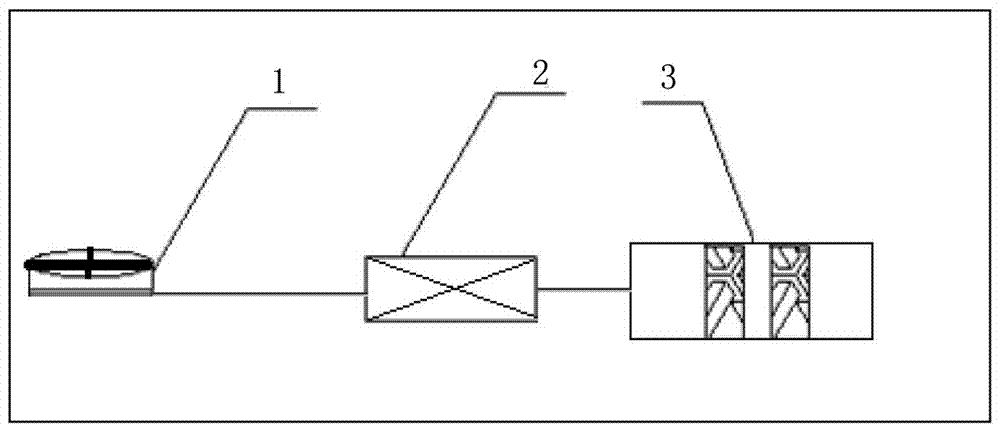

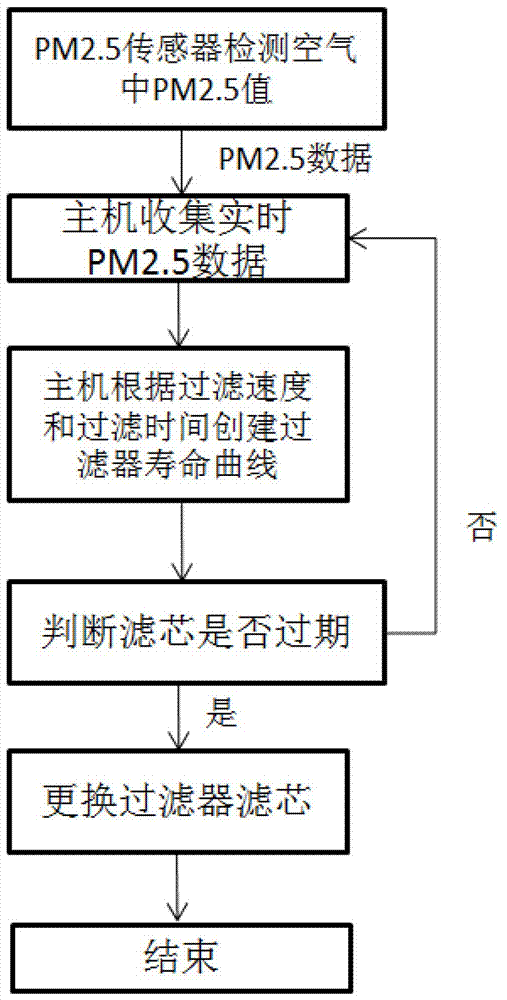

Detection system and method for vehicle PM2.5 filter

InactiveCN106872336ATimely replacementReduce filter areaPermeability/surface area analysisEngineeringData transmission

The invention discloses a detection system for a vehicle PM2.5 filter. The detection system comprises a host computer, a PM2.5 sensor and a filter. The filter filters air in a vehicle. The PM2.5 sensor is installed at an air outlet of the filter. The PM2.5 sensor detects filtered air in the vehicle. The PM2.5 sensor is connected to the host computer. The PM2.5 sensor transmits detected data to the host computer. The host computer creates a life curve based on data. The invention also discloses a detection method of a vehicle PM2.5 filter. The system and method can detect the service life of the vehicle PM2.5 filter in real time so as to timely remind the replacement of the filter.

Owner:HELLA XIAMEN ELECTRONICS DEVICE CO LTD

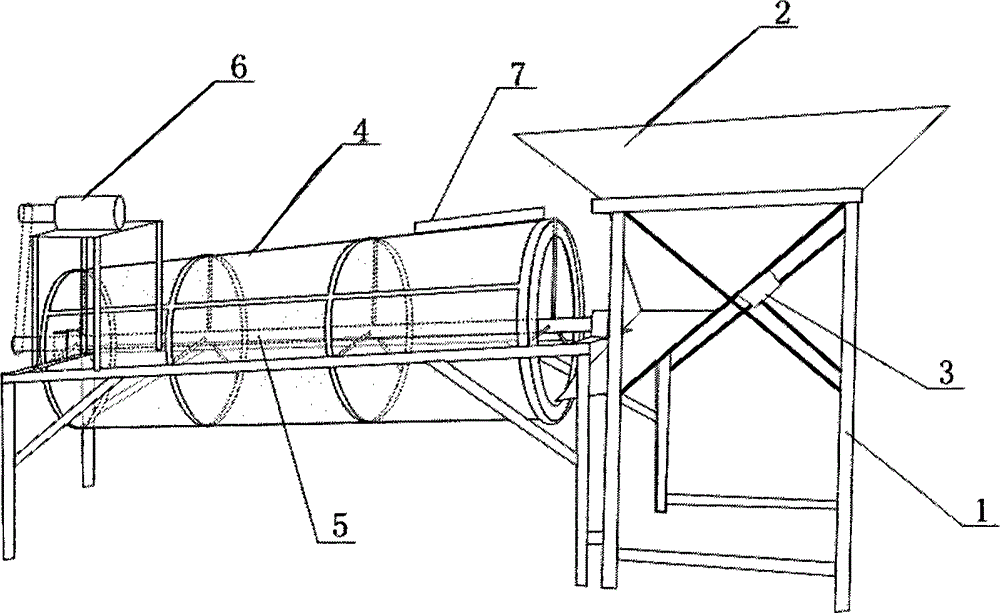

A drum screen device

InactiveCN105880146ANot easy to blockGood effect of removing impuritiesSievingScreeningEngineeringImpurity

The invention provides a drum screen device comprising a support (1), a feeding hopper (2), a bin door (3), a cylindrical screen mesh (4), a rotating shaft (5), a motor (6) and a scraping plate (7). The feeding hopper (2) is fixed on the support (1); the bin door (3) is located under the feeding hopper (2); the cylindrical screen mesh (4) is fixed on the rotating shaft (5); the scraping plate (7) is fixed on the cylindrical screen mesh (4); the rotating shaft (5) and the motor (6) are fixed on the support (1); the motor (6) is connected with the rotating shaft (5). The drum screen device has the advantages of scientific design, simple structure, convenient operation, smooth screening and mesh clogging prevention, clear classification, small vibration, low noise and long service life. The drum screen device can be widely applied to the filter, screening and impurity removal work for powdery materials, in particular the filter and impurity removal for saw dust type materials, and thus is an ideal product for replacing the conventional horizontal screen type screening machine and is worthy of vigorous promotion.

Owner:刘建国

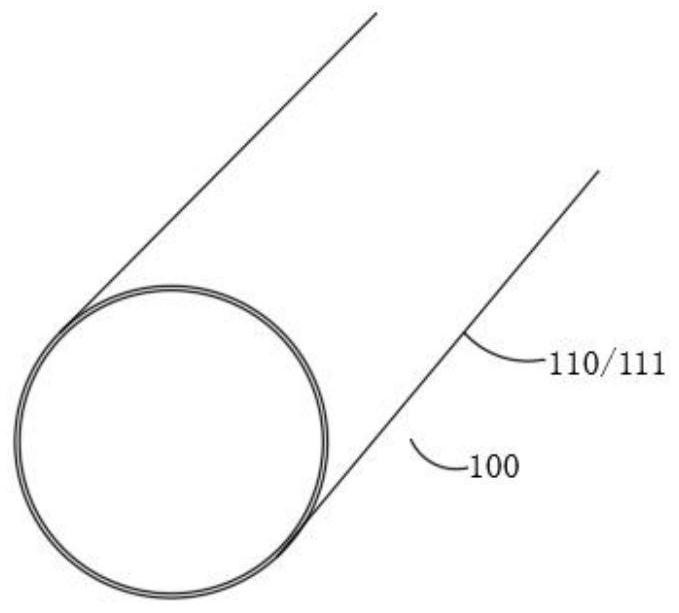

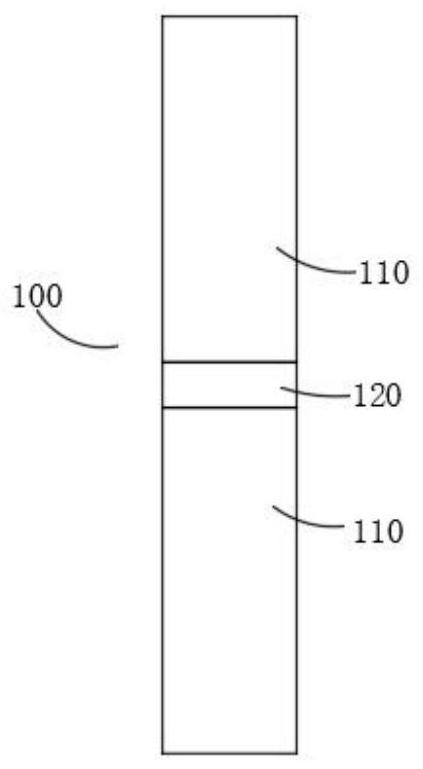

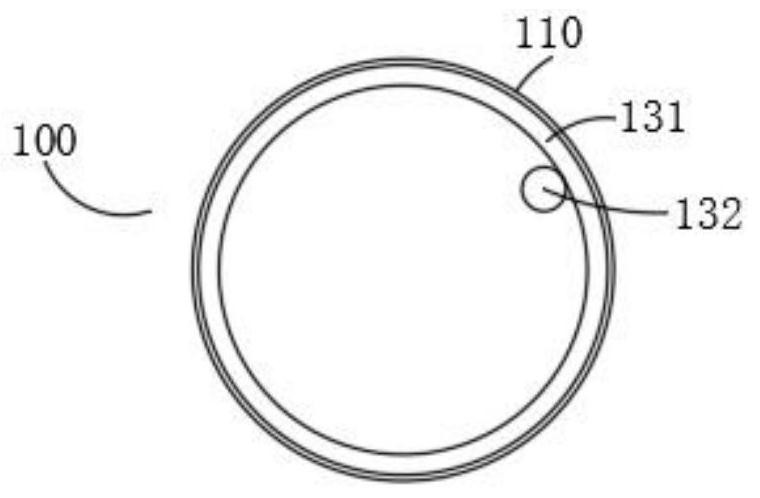

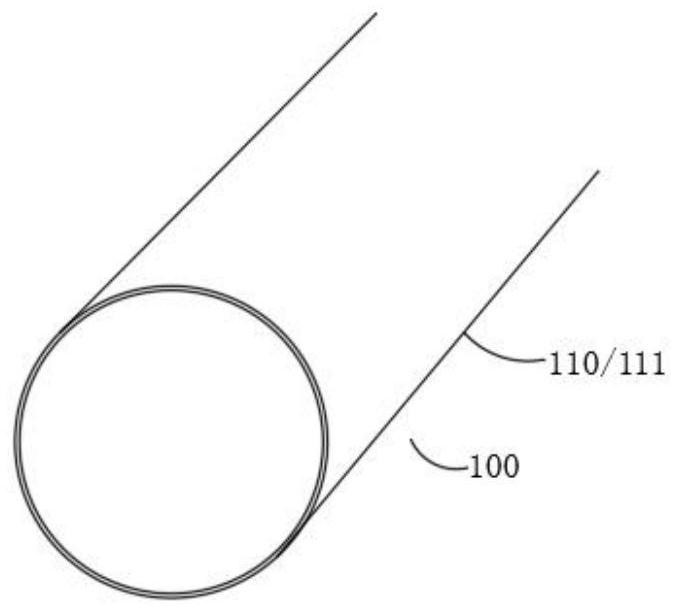

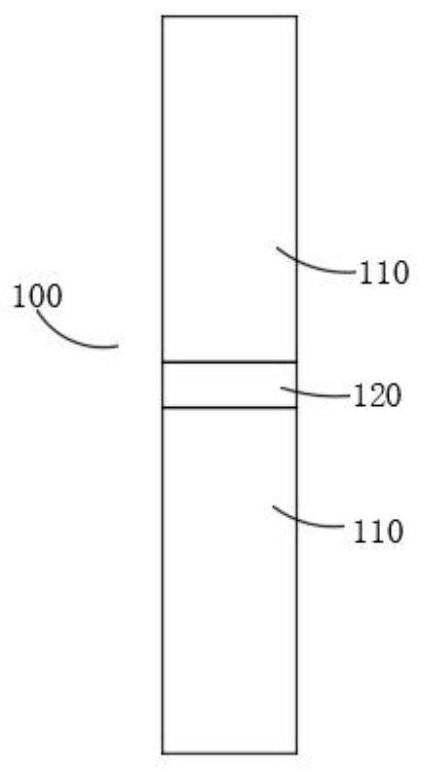

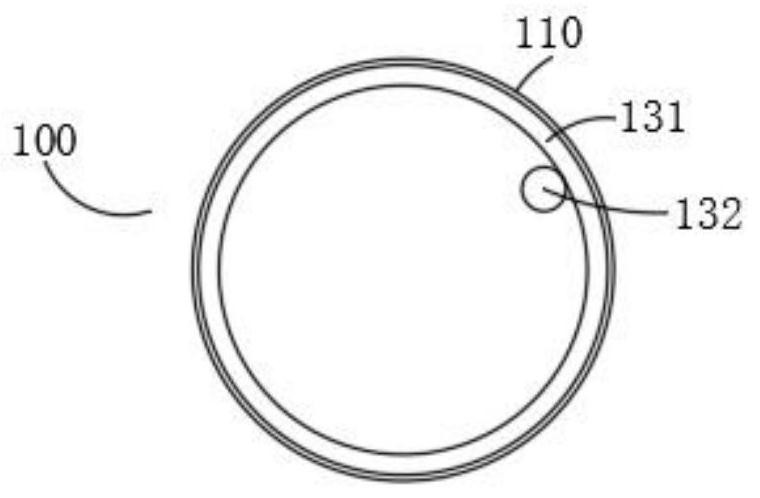

Filter element

PendingCN112237811AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a filter element. The filter element is placed in a filter to be used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on an object tobe filtered during use; the filter element comprises at least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or sheet-shaped materials taking the metal as a base body in a rolled mode and carrying out sealing processing on joints; the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm, furtherpreferably 20-60 mm, and further preferably 25-50 mm, and the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm; the lengths of the filter tubes range from 100mm to 5000 mm, preferably range from 100 mm to 3000 mm, further preferably range from 100 mm to 2000 mm, and further preferably range from 200 mm to 1500 mm. A plurality of small-diameter filter tubesare bundled, so the filtering area can be remarkably increased in a limited mounting space; the length of the filter element is reduced, so the blowback effect can be more uniformly distributed in the axial direction of the filter tubes. Therefore, the technical problems that in the prior art, a filter element is small in filtering area and poor in back flushing effectiveness are effectively solved.

Owner:CHENGDU INTERMENT TECH

Environmental protection treatment device for industrial sewage

InactiveCN108996789AStir wellAvoid cloggingWater/sewage treatment by irradiationSpecific water treatment objectivesIndustrial waste waterWater resources

The invention discloses an environmental protection treatment device for industrial sewage. The environmental protection treatment device comprises a base, a water inlet, grooves and filtering frames,wherein a tank body is arranged on the base; a transmission chain is connected with the lower part of a motor; the water inlet is located at the left end of the top part of the tank body; the top part of the tank body is provided with connecting shafts; each short rod is connected with the upper part of a long rod; the grooves are symmetrically arranged at the inner sides of the tank body; a filter screen is fixedly arranged in the grooves; the central end of the interior of the tank body is provided with a first filtering layer; each filtering frame is arranged below a flow guiding opening;the inner wall of the upper end of the tank body is provided with heating pipes; the position of the lower end of the tank body is provided with a second filtering layer; and the front surface of thetank body is provided with chutes. The environmental protection treatment device for the industrial sewage provided by the invention has the following advantages: through arrangement of an active carbon filtering layer in the tank body, multi-layer filtering of the industrial wastewater can be conveniently realized, so filtered water is cleaner and can be reused; utilization efficiency of water resources is improved; and the effect of environmental protection is achieved.

Owner:安徽通全孵化器管理有限公司

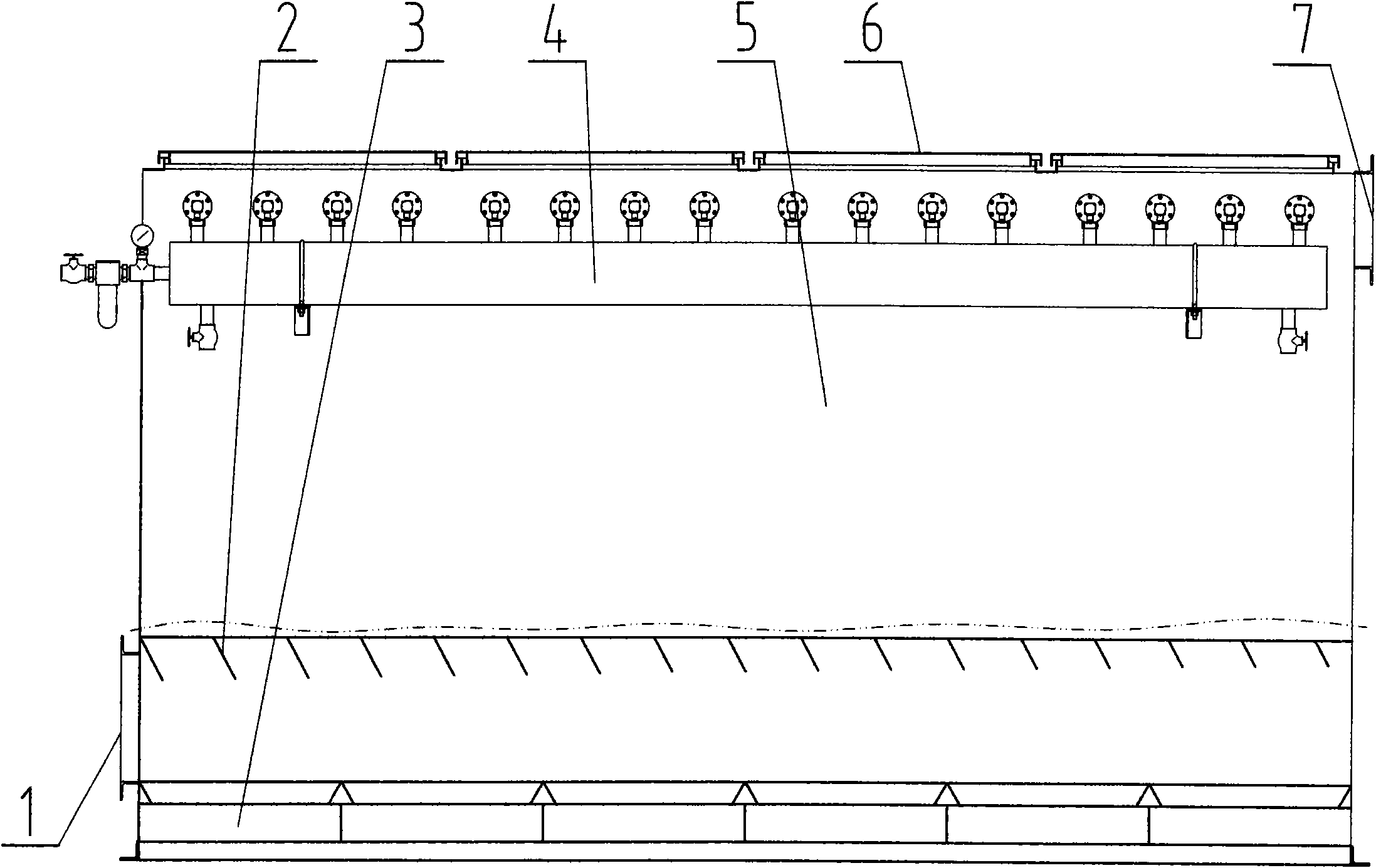

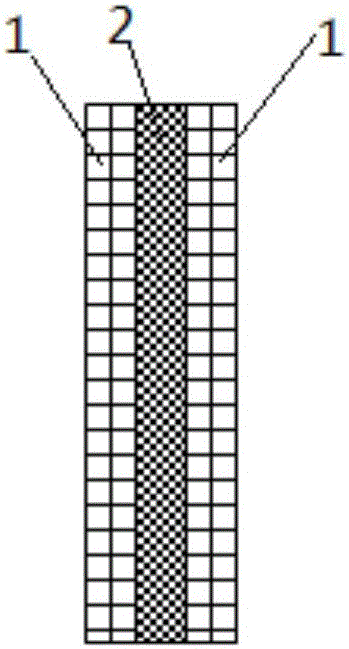

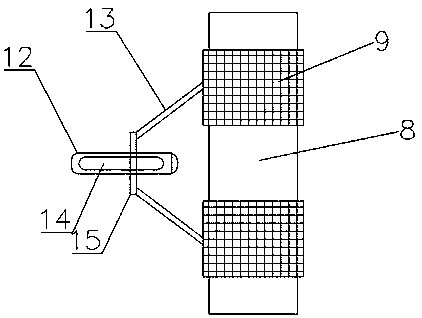

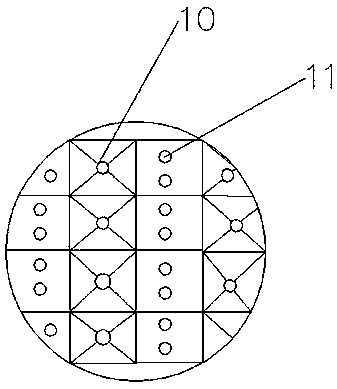

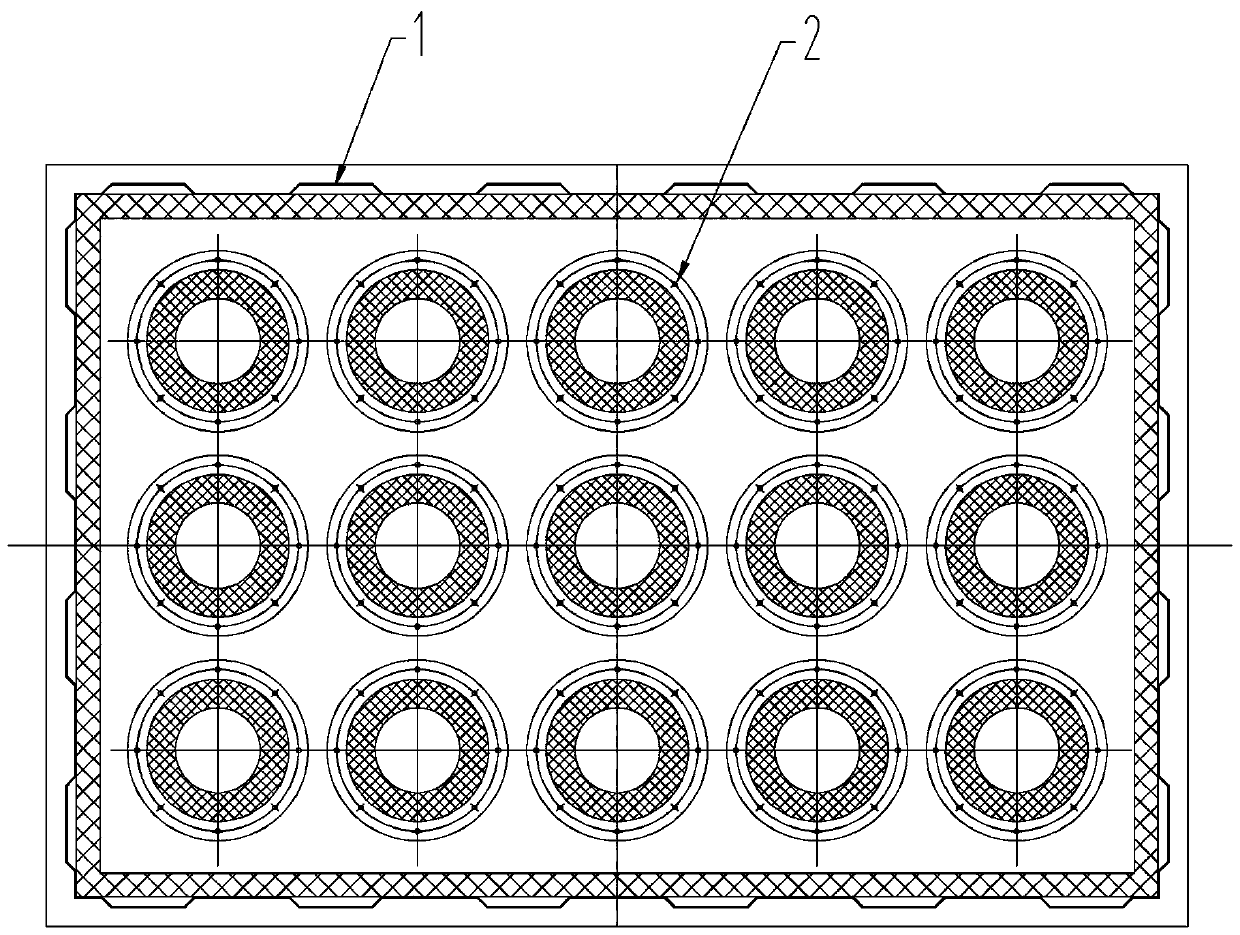

High-efficiency carbon fiber adsorption box

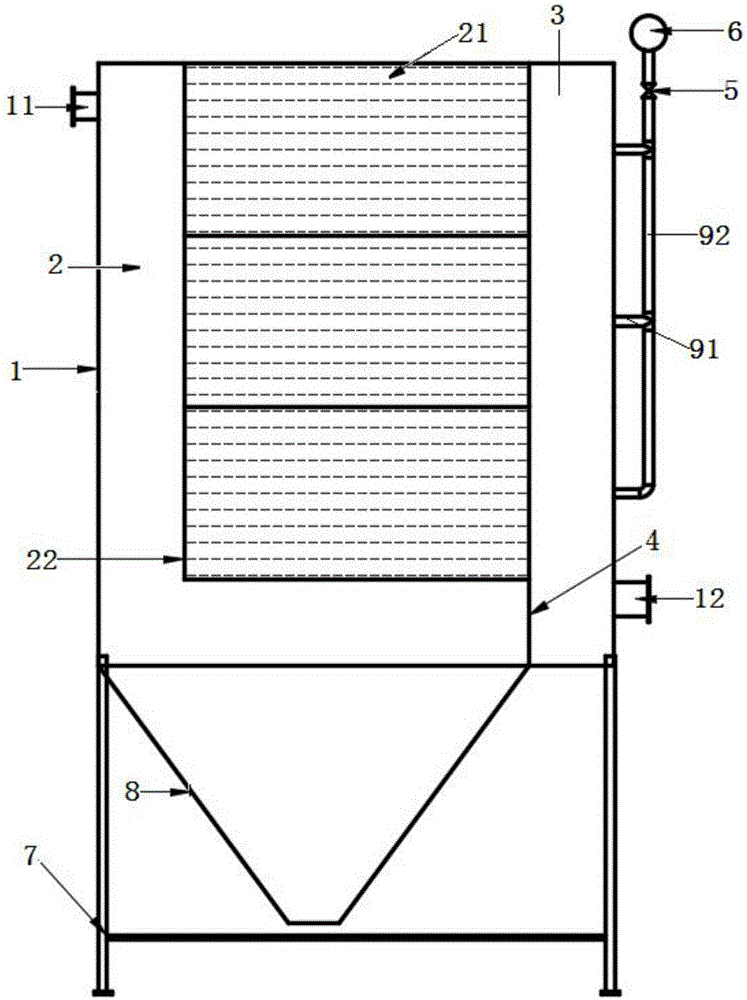

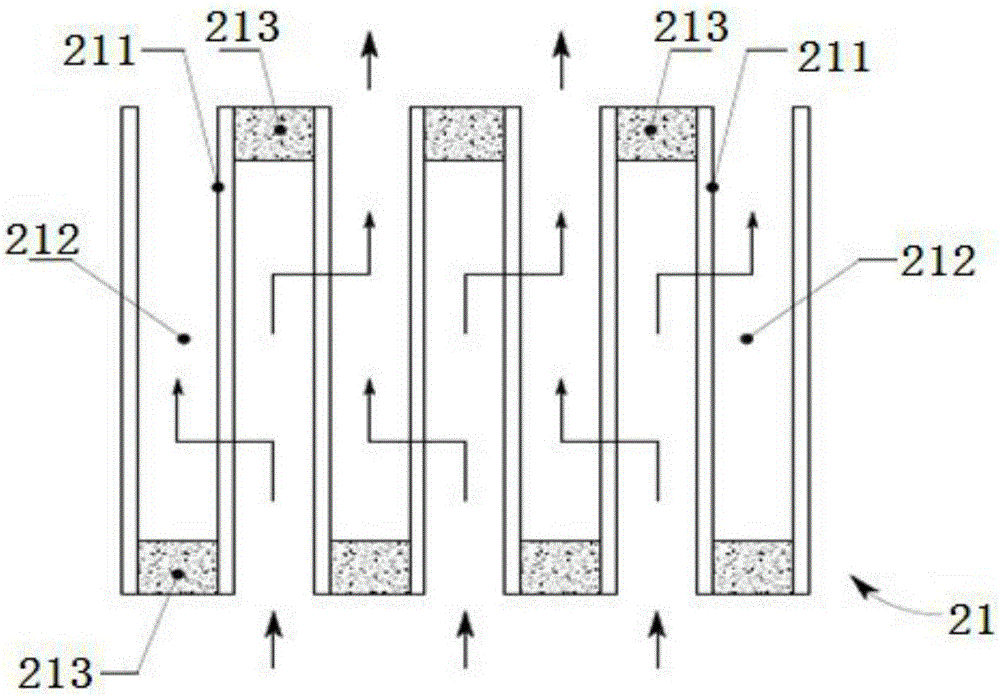

PendingCN107774088AImprove purification rateReduce filter speedGas treatmentDispersed particle separationFiberCarbon fibers

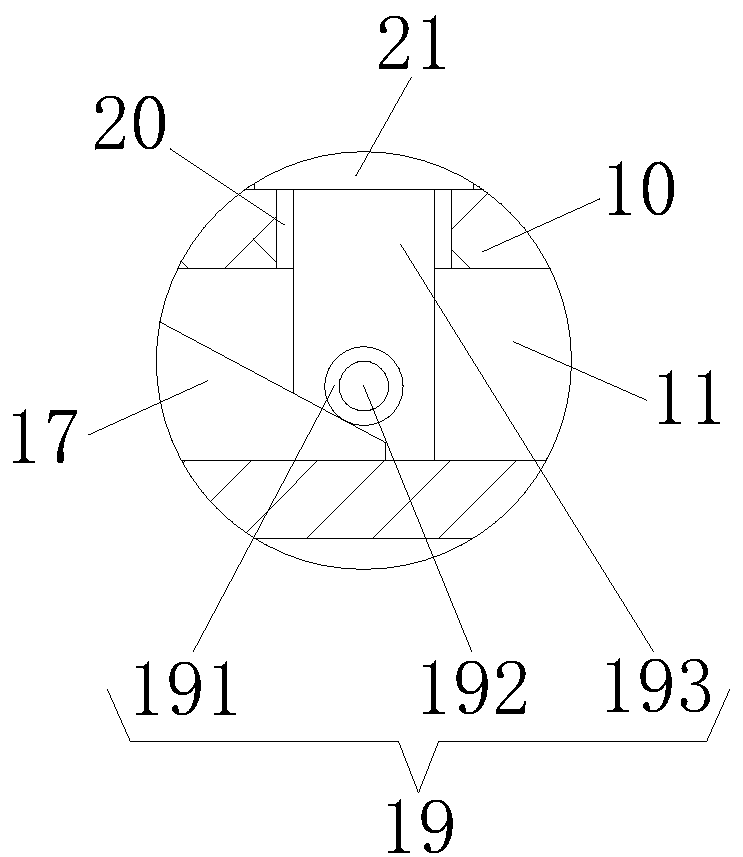

The invention discloses a high-efficiency carbon fiber adsorption box. The box comprises a box body (1) and carbon fiber cylinders (2), the carbon fiber cylinder (2) is arranged on a supporting platein the box body (1), and 3 * 5 carbon fiber cylinders (2) are uniformly arranged in the box body (1) of the standard adsorption box with the length being 2400 mm and the width being 1600 mm. The fifteen carbon fiber cylinders (2) are uniformly arranged in the box body (1) of the standard adsorption box with the length being 2400 mm and the width being 1600 mm, so the filtering wind speed is less than 0.2 m / s, the filtration approximates to a stationary state, the exhaust gas purifying rate of the carbon fiber is greatly improved, and the adsorption box is suitable for being promoted and used.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP

Rice washing wastewater treatment device

InactiveCN107915338AReduce the burden onImprove recyclingTreatment involving filtrationMultistage water/sewage treatmentWater treatmentFiltration

The invention discloses a rice washing wastewater treatment device, which comprises a filter device and an air bubble separation device. The filter device includes a filter pool, a filter net is arranged in the filter pool, a waste water inlet and a waste water outlet are arranged in the filter pool, and the waste water outlet is separated from the air bubbles. The device is connected, and the bubble separation device includes a bubble generator and a bubble separation chamber, and the bubble generator is connected with the bubble separation chamber. Through the rice washing wastewater treatment device of the present invention, the purpose of purifying and treating the rice washing wastewater is achieved.

Owner:CHENGDU WENDA MAOYUAN TECH

Drum type granular dust collector

InactiveCN1470307ACompact structureEasy maintenanceDispersed particle filtrationEngineeringDust collector

The invention discloses a kind of barrel particle dust catcher. It has a combined dust catching barrel which is formed by several dust catching units vertically in the catcher, the top of the barrel is connected with the air gathering room. There's reversal inlet and outlet at the two ends of the room. There is an ash gathering room which has an ash outlet at the bottom of the sealed end of the barrel.

Owner:北京金信合达能源科技有限公司

Rapid primary filtering device for commercial concrete sewage

InactiveCN110721518AClose contactIncrease the speed of descentMoving filtering element filtersElectric machineryStructural engineering

A rapid primary filtering device for commercial concrete sewage comprises a filter shell, the inner wall of the filtering shell is fixedly connected with a first supporting plate, first supporting columns are slidably connected to the inner wall of the first supporting plate, a filter screen is fixedly connected to the upper surfaces of the first supporting columns, the inner wall of the filter screen is slidably connected with the inner wall of the filtering shell, and baffle plates are fixedly connected to the front side and the rear side of the inner wall of the filtering shell and the upper surface of the first supporting plate. When the device filters sewage, a drive motor is turned on to rotate a push plate, a push block moves left and right under the action of a spring, and a supporting bock moves up and down through an inclined surface on the push block in order to increase the downward sliding speed of sands and stones on the filter screen, and the sand and stones clamped on the filter screen are vibrated out, so the situation that sewage cannot quickly pass through the filter screen and the filtering speed is reduced due to the fact that many sands and stones are clampedon the filter screen is prevented.

Owner:徐州杰汇环保科技有限公司

Degerming and water purifying argil filtering material, as well as preparation method and application thereof

InactiveCN108002861ASolve the defect of inconvenient useEasy to useTreatment involving filtrationWater/sewage treatment using germicide/oligodynamic-processEnvironmental engineeringRice hulls

The invention discloses an adegerming and water purifying argil filtering material, as well as a preparation method and application thereof. The materials comprises following components according to the following matching ratio: 130g-150g of clay, 30g-50g of a pore-forming agent, and 90ml-110ml of water, wherein the pore-forming agent is formed by 0.8mm rice husks or 1.2mm rice husks. according tothe adegerming and water purifying argil filtering material provided by the invention, the pore size and quantity of pottery sheets are controlled by controlling the mixing ratio and a firing method,the water purification effect is good and the use is convenient and easy.

Owner:XIAMEN UNIV OF TECH

Bag deduster prepared by reconstructing electric deduster

InactiveCN108671646AWell mixedReduce delayDispersed particle filtrationMechanical engineeringEngineering

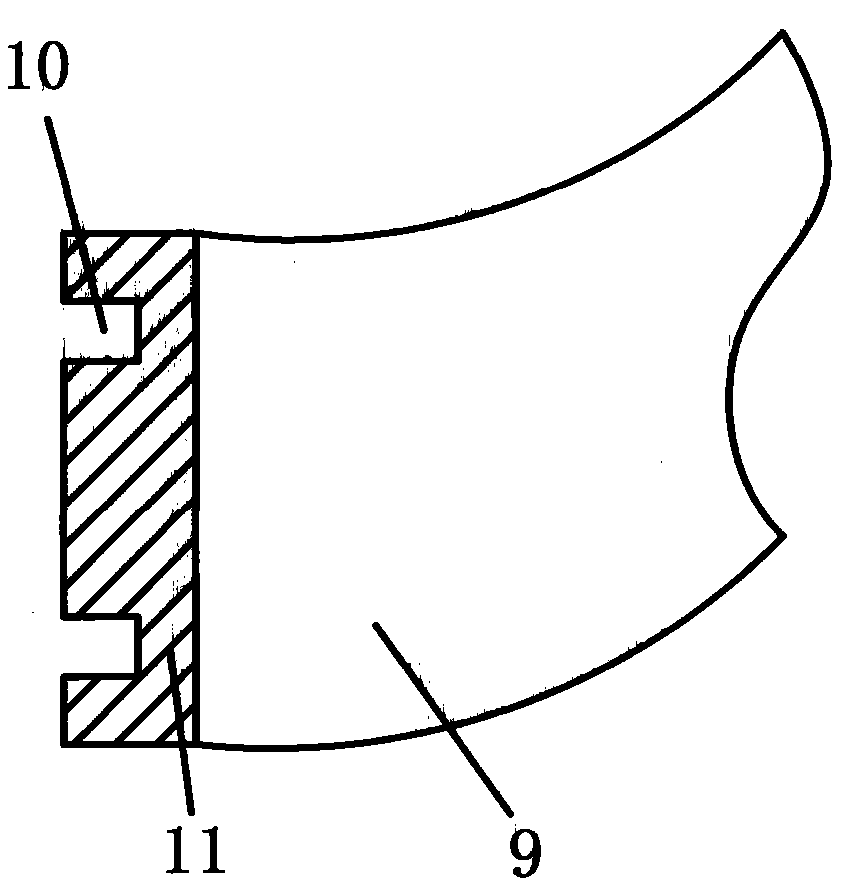

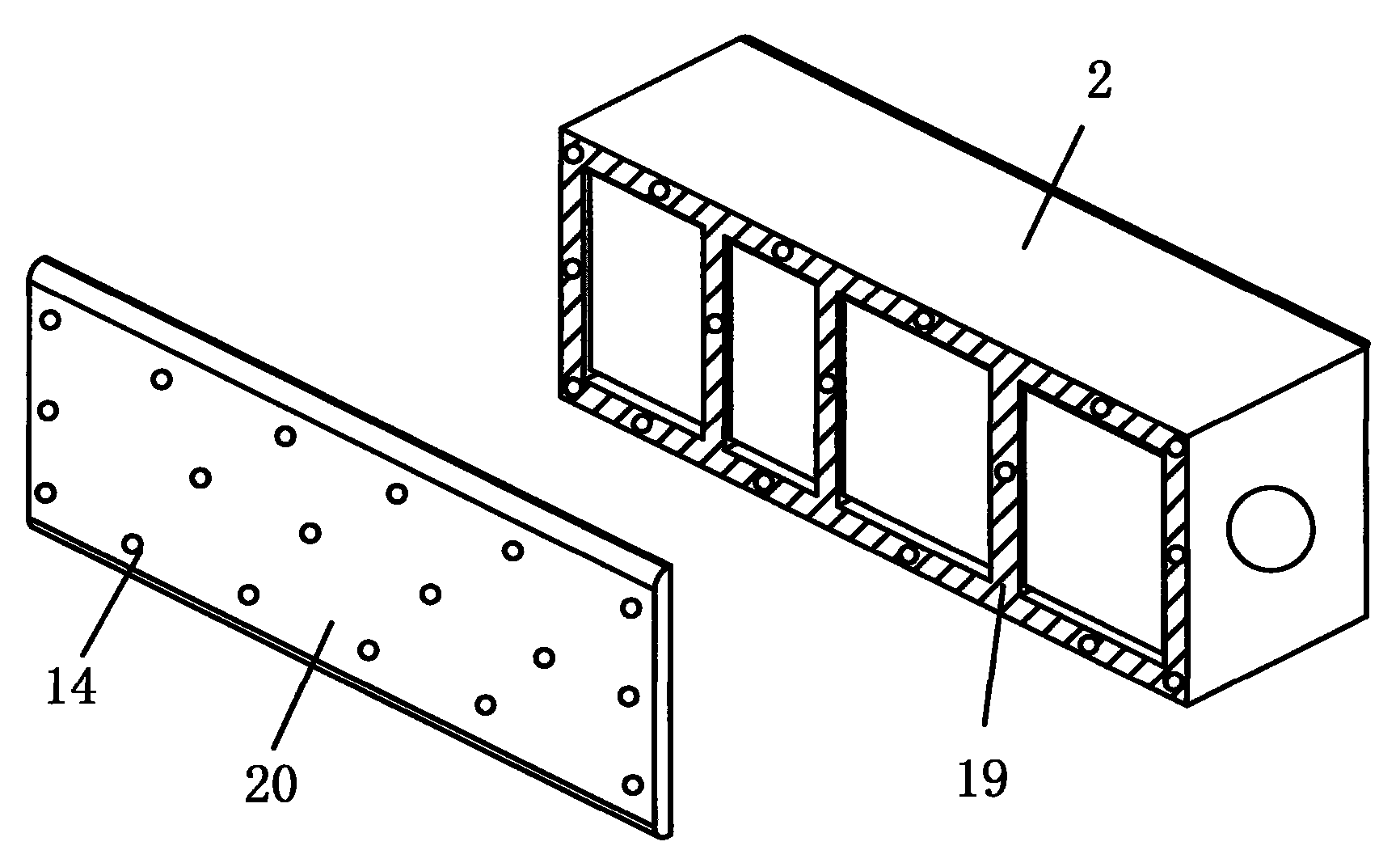

The invention relates to a bag deduster prepared by reconstructing an electric deduster. The bag deduster comprises an electric deduster, an ash bucket (2), a shell (1), and an inlet horn, and an outlet horn. An air purifying box (3), which is composed of a dust removal system, a lower porous board (4), and an upper inspection rack (5), is installed in the upper part of the shell (1). The bag deduster is characterized in that an air duct (11) is arranged on two sides of the shell (1); the upper part of the air duct (11) is connected to the air purifying box (3), the lower part stretches into the shell (1) through a connection pipe (14); a guide plate (16) is obliquely arranged in the air duct (11), the air duct below the guide plate (16) is a lower air duct (12), which is communicated withthe inlet horn (17), the air duct above the guide plate (16) is an upper air duct (13), which is communicated with the outlet horn (18); and the cross section of the inlet of the shell (1) is provided with a partition plate (19). A plug-in air duct technology is adopted, the construction amount and deduster downtime are both reduced, the reconstruction period is shortened, and the construction efficiency and air quality are both improved.

Owner:ANHUI CHENRUI ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION SCI & ENG

Foreign matter separating and filtering device for compressed airflow

ActiveCN113262572AAvoid cloggingAvoid dischargeHuman health protectionDispersed particle filtrationForeign matterStructural engineering

The invention provides a foreign matter separating and filtering device for compressed air flow, and relates to the technical field of filters, in order to solve the problem that when an existing compressed air filtering device is used, impurities in air are prone to blocking filtering holes, the foreign matter separating and filtering device comprises a body, a push plate and an inserting groove, and a fixing plate is arranged at the top of a mounting plate; the mounting plate is arranged at the side end of the flow guide plate; filter holes are formed in the top of an inner plate, and the inner plate is mounted in the main body; and inner grooves are formed in the two sides of the main body, and baffles in the inner grooves are installed at the side ends of the scraping plates. A filtering hole is formed in the top of a bottom groove, and the bottom groove is formed in the main body; an open groove is formed in the top of the push plate, a rotating rod is slidably mounted in the middle of the push plate, and a cross rod outside the push plate is mounted at the bottom of the rotating rod; and the inserting groove is formed in the inner side of the water tank, and a pressing plate is arranged outside the inserting groove and is mounted at the top of a carrier plate through a connecting rod. And filtering holes in the filtering device are cleaned by using a push plate, so that blockage is prevented.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

Filter

PendingCN112237810AReduce areaSolve the costCombination devicesDispersed particle filtrationProcess engineeringControl theory

The invention discloses a filter. The filter comprises a filter structure, and the filter structure comprises at least two filter elements which are arranged at intervals; the filter element comprisesat least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking the metal as a base body in a rolling manner and performing sealing processing on joints; and the outer diameter of the pipe body formed by rolling is only 20-200 mm. The bundled filter element formed by bundling a plurality of small-diameterfilter tubes is adopted, so that the filtering area can be remarkably increased; for a filter with a large size, the weight of a single filter element can be reduced by adopting a plurality of cluster type filter elements while a high filtering area is ensured, and the installation is simplified; for a filtering structure needing a large number of filter tubes, a plurality of cluster type filterelements are respectively mounted, so that a relatively uniform blowback effect can be ensured. Therefore, compared with the prior art, the filter has the advantages that a larger filter area can be achieved, and the problems of installation and blowback after the filter pipes are bundled are solved.

Owner:CHENGDU INTERMENT TECH

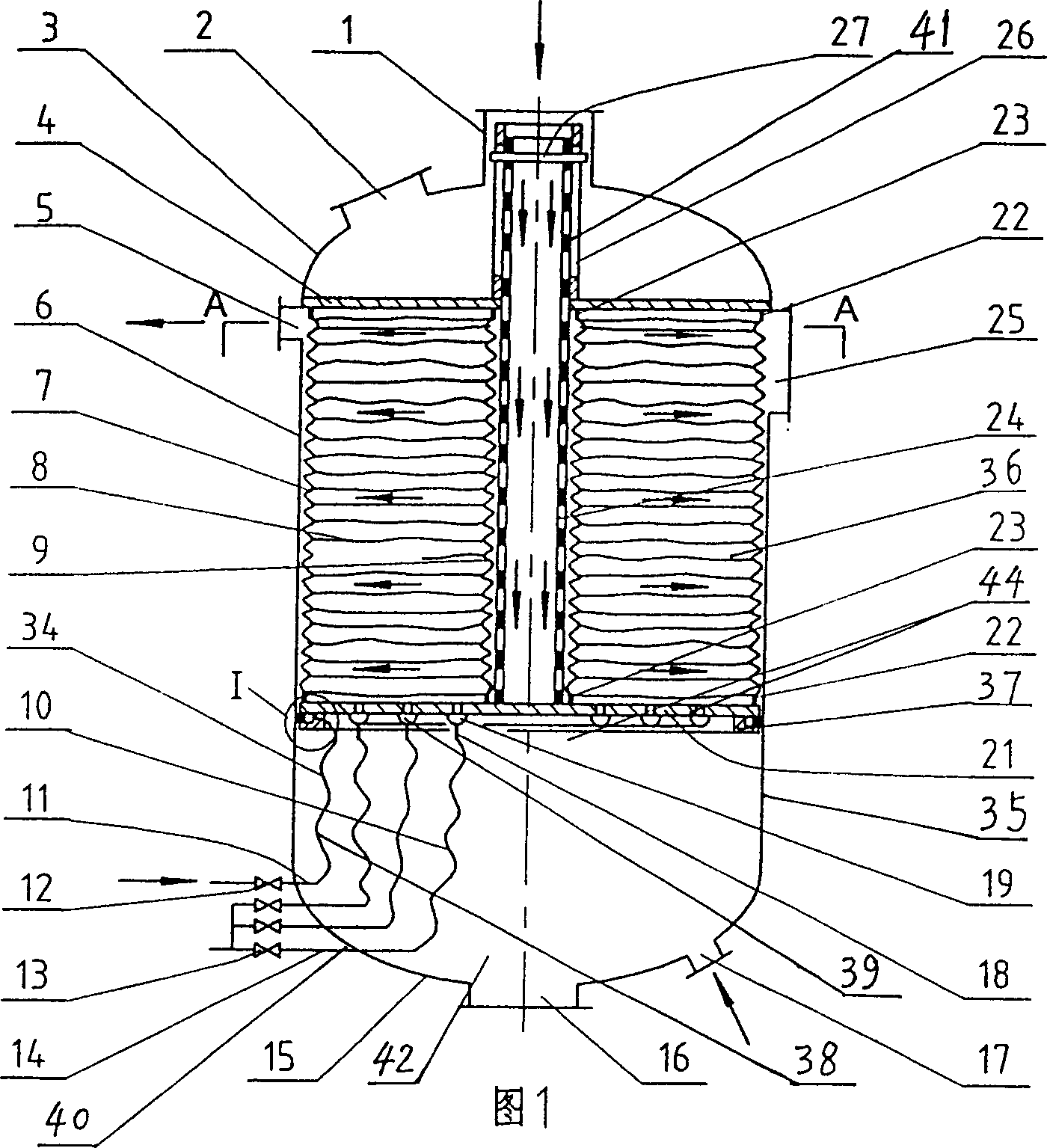

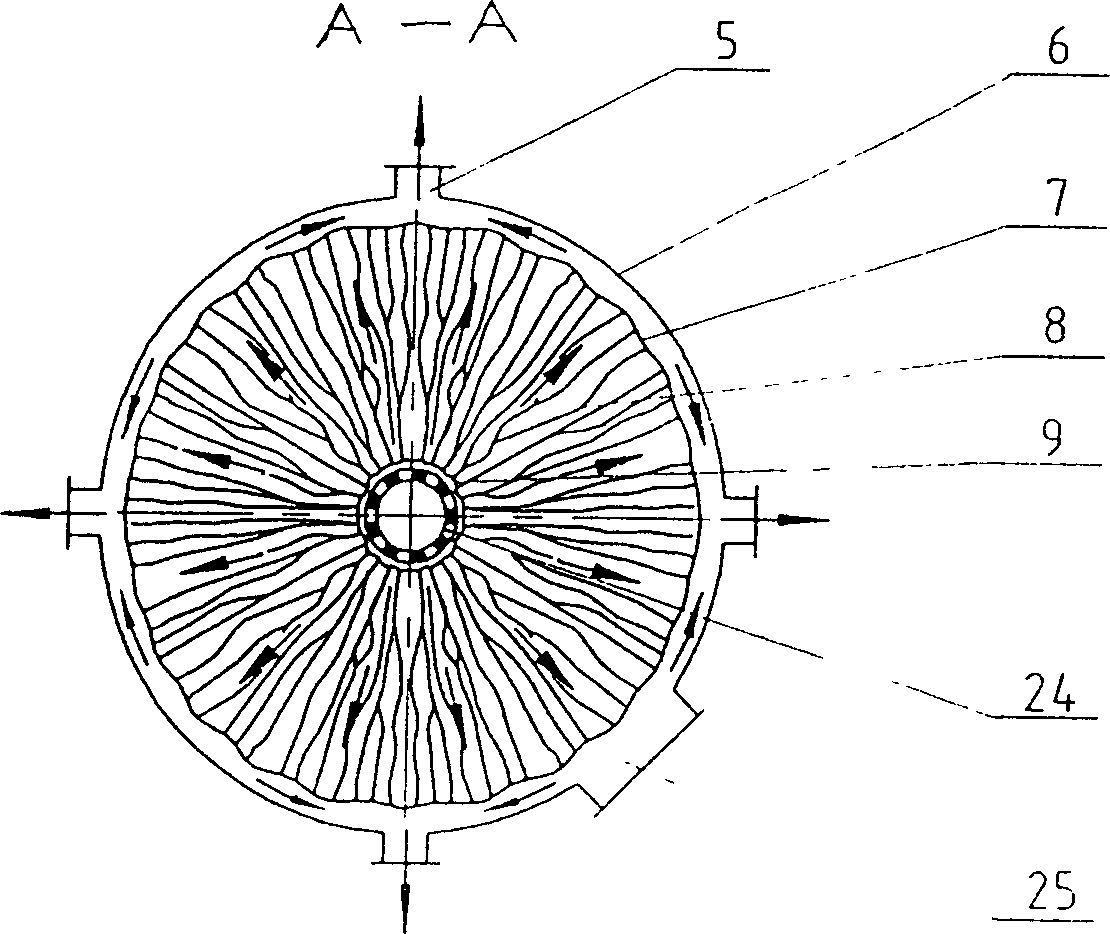

Radiant flux fiber filter

InactiveCN1265863CEfficient use ofLarge sewage interception capacityLoose filtering material filtersGravity filtersFiberWork cycle

The radial flow fiber filter includes container, water inlet, water outlet, horizontal fixed disc and floating disc, fiber stuffing set between the fixed disc and the floating disc, stuffing density regulator, and air distributor. It features the fiber stuffing including layered multiple fiber tows connected horizontally to inner and outer flexible netted cylinders, which have ends connected to the fixed disc and the floating disc separately; the inner flexible netted cylinder provided with vertical porous water distributing pipes fixed to the floating disc; the stuffing density regulator comprising pressure regulating sealer and container water injecting cavity; and the air distributor comprising annular air distributing chamber, air distributing holes in the annular air distributing chamber and the floating disc and controlling pipeline connected together. The present invention has adjustable stuffing density, great filtering capacity and other advantages.

Owner:乔国章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com