Explosion-proof-type dust collector for mine

A mine-used explosion-proof and dust collector technology, which is applied in the direction of chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve problems such as inability to meet dust removal requirements, poor dust removal effect, and equipment movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

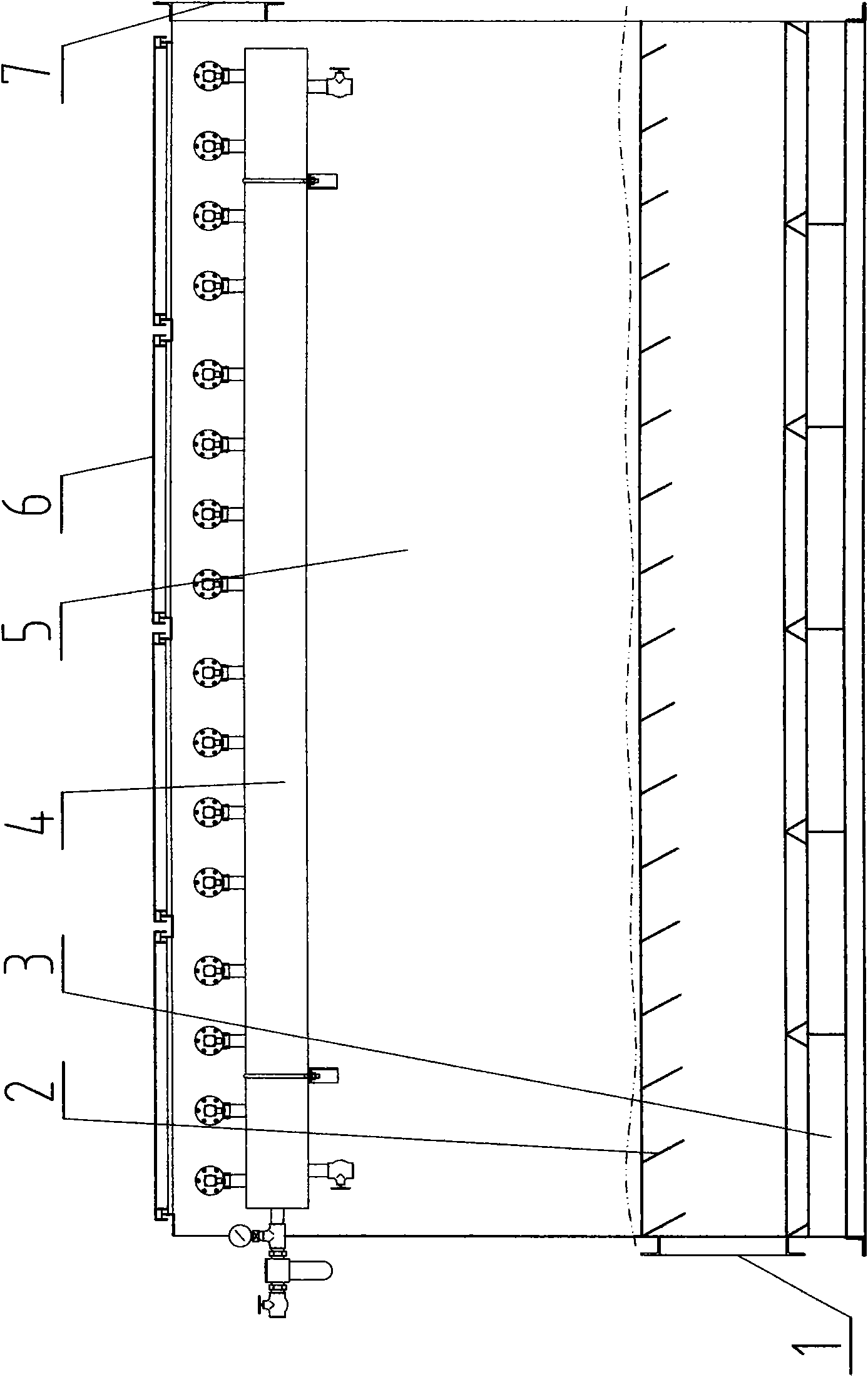

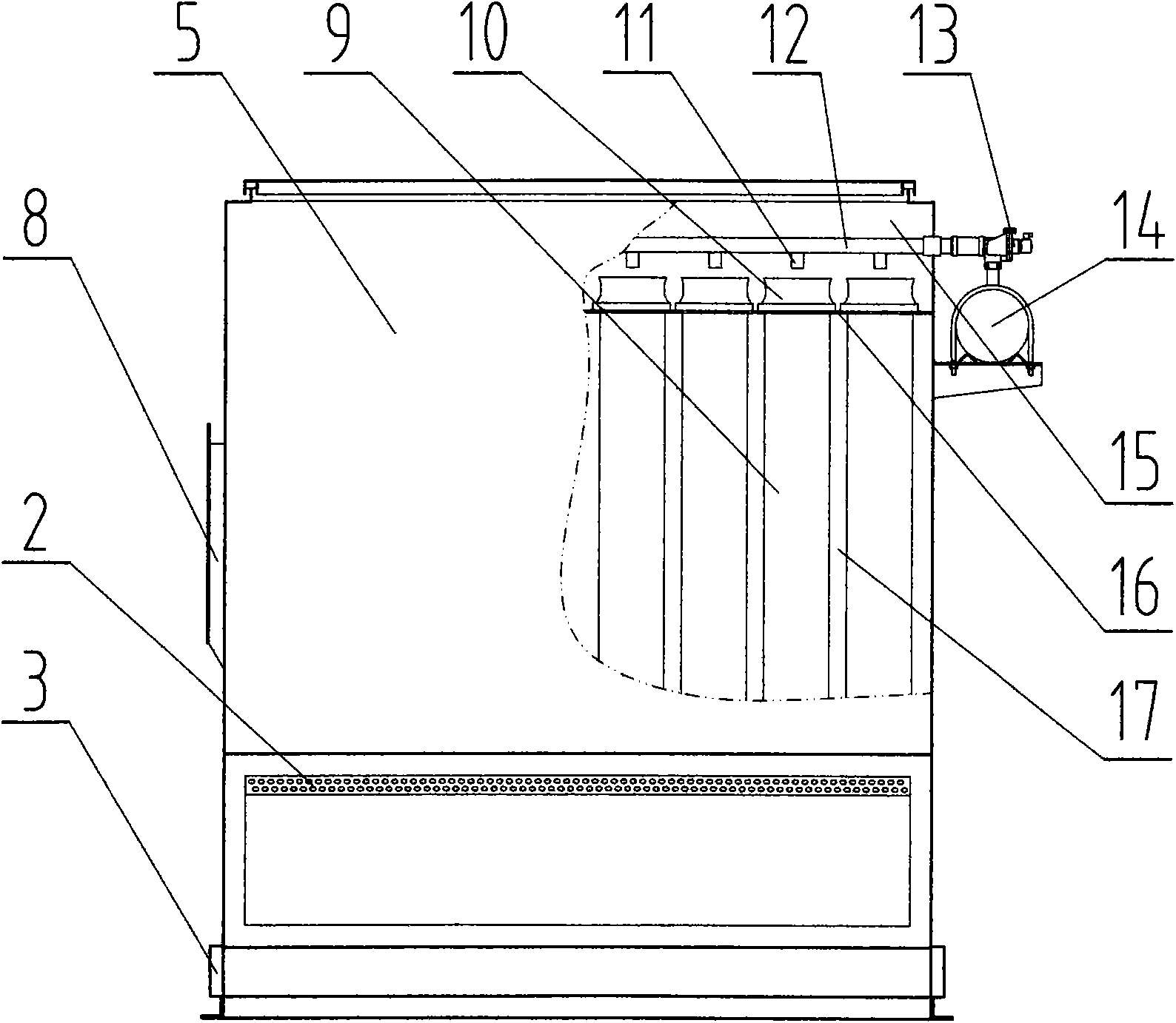

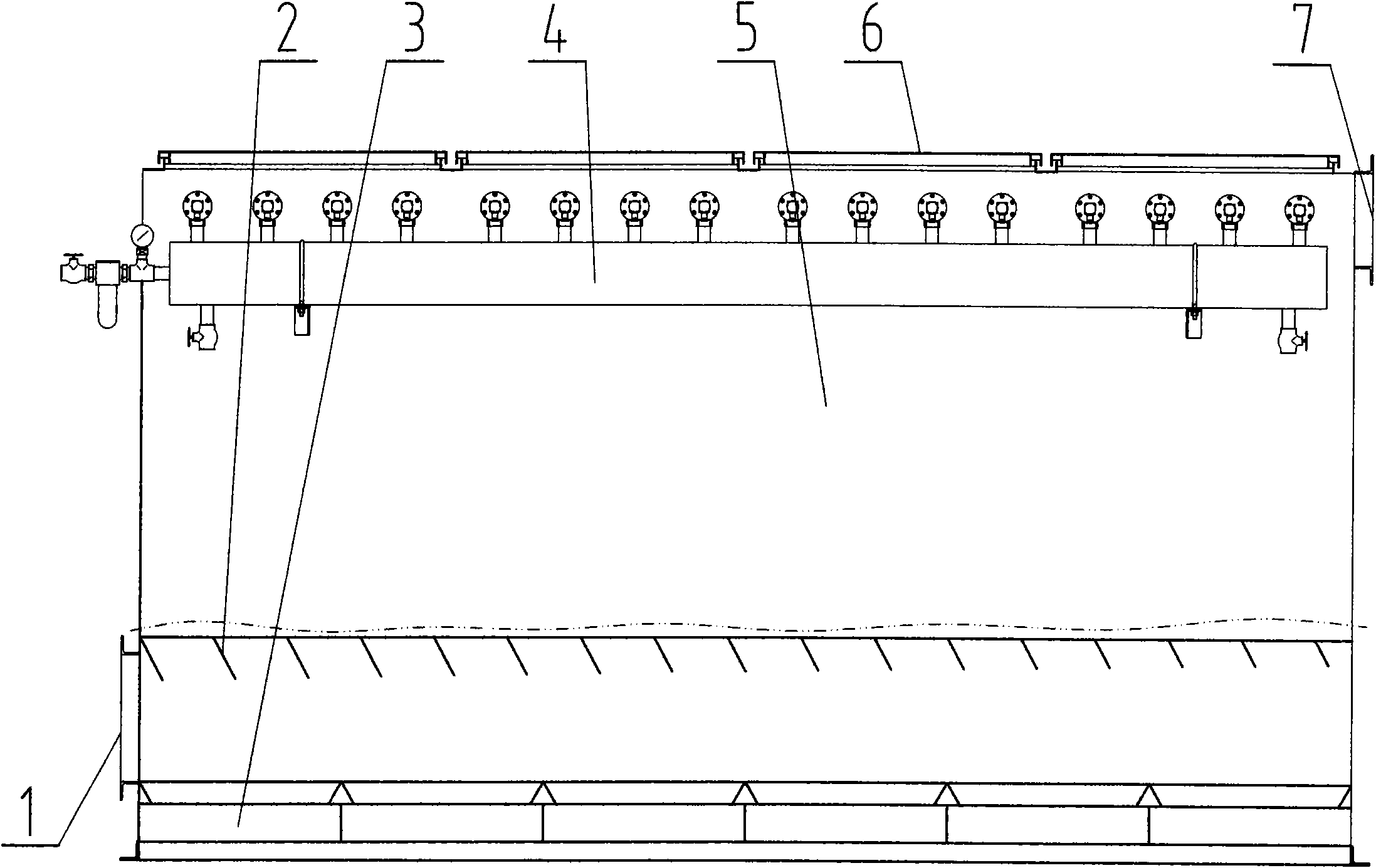

[0013] figure 1 and figure 2 Among them, the mining explosion-proof dust collector includes a box body 5, a dust removal injection system 4, an explosion-proof device 8, an air distribution plate 2, and an ash discharge drawer 3. The box body 5 is a cuboid structure, the top of the box body 5 is provided with an upper cover plate 6, and the inner upper part of the box body 5 is provided with a flower plate 16, and the space above the flower plate 16 is the clean air chamber 15, the flower plate 16 The space below is dust removal chamber 17. The rear end of the clean air chamber 15 is provided with an air outlet 7 . The dust removal injection system 4 contains a filter cartridge 9 and an injection device. The filter cartridge 9 is located in the dust removal chamber 17 and its upper end is arranged on the flower plate 16 . The blowing device comprises a pulse valve 13 , a blowing pipe 12 , a nozzle 11 , an air storage tank 14 and a flow guiding device 10 . Air storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com