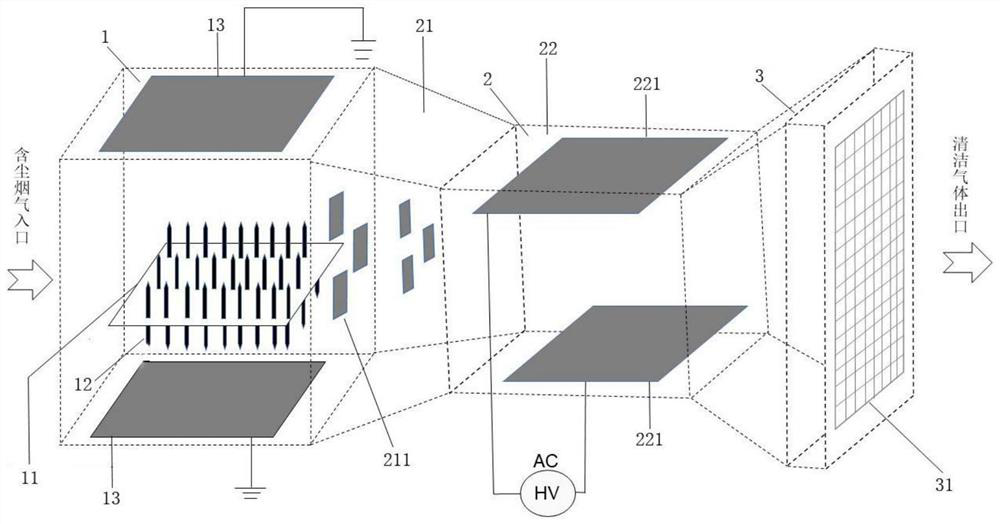

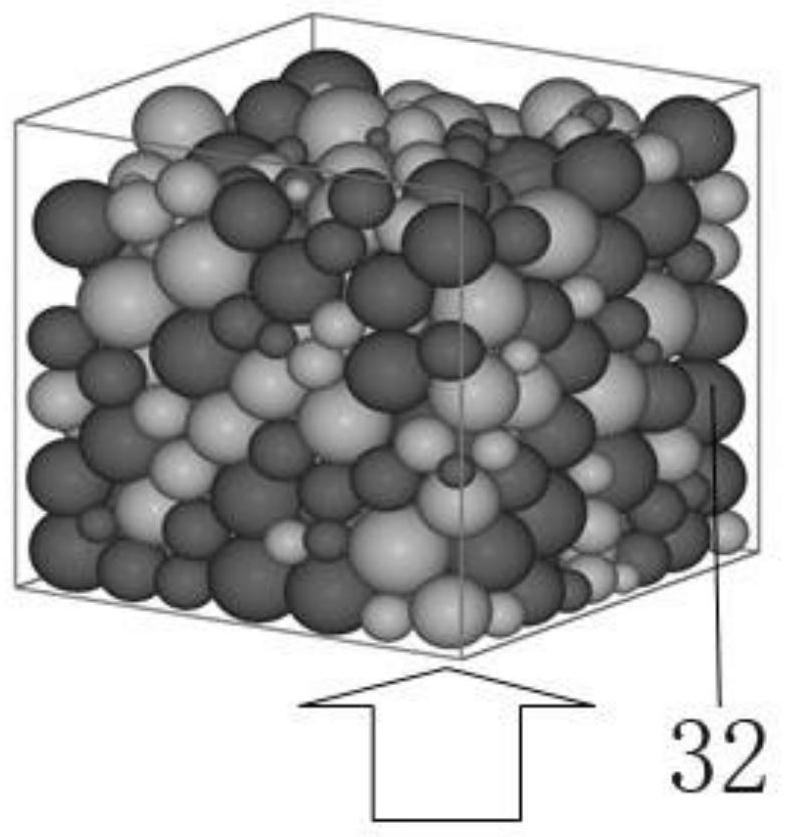

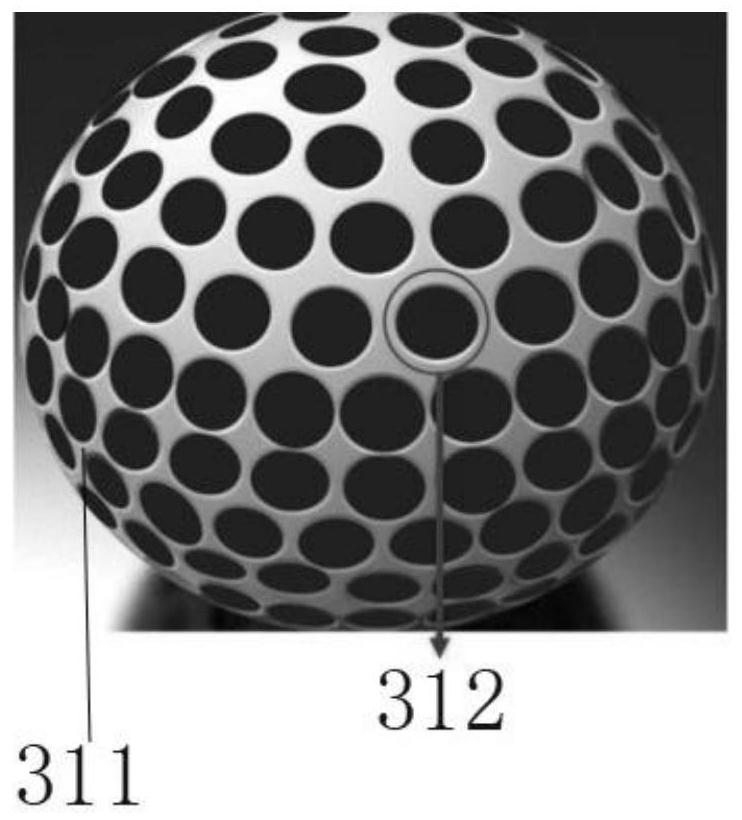

Enhanced coalescence and efficient granular layer filtering device for ultrafine particles

A particle layer filtration and ultrafine particle technology, which is applied in the field of flue gas purification, can solve the problems of efficient purification of difficult ultrafine particles, submicron particles, and low charge of ultrafine particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Performance Testing:

[0036] According to the process parameter values in Table 1 below, six groups of different operating conditions were set up, and the dust removal efficiency of the device was tested respectively. It can be seen that: the nanosecond pulse power supply parameters (such as pulse frequency, peak voltage) Combined area power parameters (such as frequency, peak voltage) and dust particle size all have an impact on the filtration performance. The filter efficiency of the device for 0.01-10μm fly ash particles can reach 99.99%. Increasing the nanosecond pulse power supply voltage in the charging area and the alternating power supply voltage in the alternating electric field coagulation area can improve the filtering effect on submicron particles. When the pulse repetition frequency and peak voltage of the nanosecond pulse power supply in the electric zone are 50Hz and 61.8KV respectively, and the frequency and peak voltage of the alternating electric po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com