High-efficiency carbon fiber adsorption box

A carbon fiber and adsorption box technology, applied in the field of organic waste gas purification, can solve the problems of low flow rate and affecting the purification efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

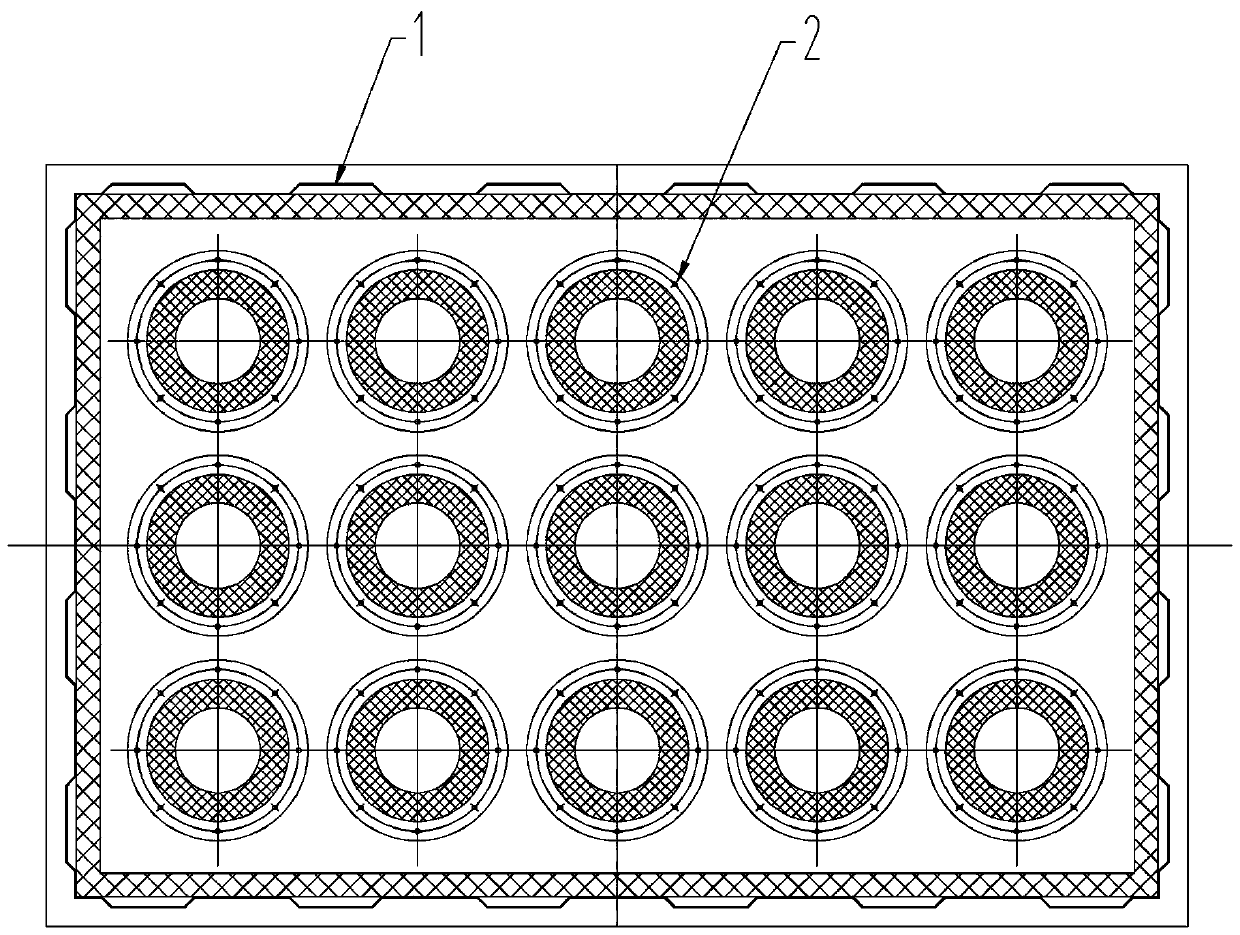

[0015] Such as figure 1 Shown: a high-efficiency carbon fiber adsorption box, including a box body 1 and a carbon fiber tube 2, the carbon fiber tube 2 is installed on the support plate in the box body 1, and is evenly distributed in the box body 1 of a standard adsorption box with a length of 2400 mm and a width of 1600 mm. Set 3*5 carbon fiber tubes 2, the carbon fiber tubes 2 are arranged vertically and horizontally in the box body 1 and the thickness of the carbon fiber layer on the carbon fiber tube 2 is smaller than the inner cavity radius of the carbon fiber tube 2 and the thickness of the carbon fiber layer is not less than 60mm; in the above structure, any The distance between the outer walls of the carbon fiber layer on two carbon fiber cylinders 2 is not less than twice the thickness of the carbon fiber layer on the carbon fiber cylinder 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com