Closed cloth-bag-type low-pressure ash-removing dust remover

A dust collector and bag-type technology, which is applied in the field of bag-type low-pressure dust removal and dust collectors, can solve the problems of inconvenient replacement of filter bags and bag cages, large volume, and large overall volume, so as to ensure the blowing effect, reduce the volume, increase the The effect of filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the embodiments shown in the drawings.

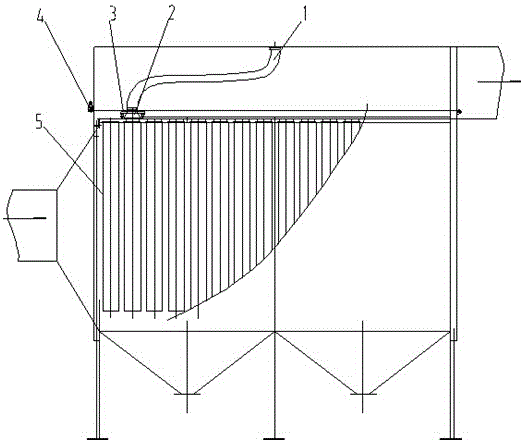

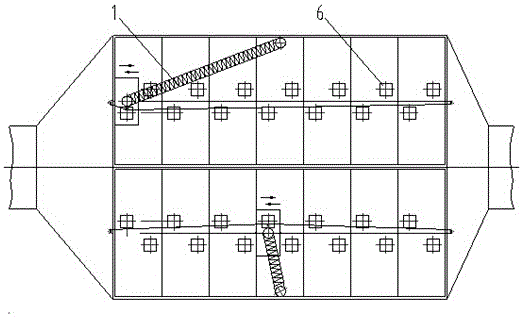

[0027] As shown in the figure, the low-pressure dust-cleaning bag-type dust collector is mainly composed of foundation, bracket, box, filter bag room, clean air room, filter bag, bag cage, flower plate, etc., dust cleaning system, ash hopper, etc.

[0028] The components in the picture include: hose 1, dust cover 2, trolley 3, reducer 4, filter bag 5, and clean air chamber 6.

[0029] The low-pressure cleaning bag dust collector requires that the air pipe must have high temperature resistance, corrosion resistance, flexibility, and stretch. The dust removal system is driven by a set of chains (driven by a motor and a reducer) to drive the dust removal cover and trolley to move linearly back and forth along the direction of the inlet and outlet arrangement on the track to perform reverse air blowing (dust removal). It can be realized with a set of electrical contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com