A drum screen device

A technology of trommel screen and screen mesh, which is applied in the direction of filter screen, solid separation, grille, etc. It can solve the problems of affecting the filtering speed and impurity removal effect, the wood chips cannot be finely sorted and stacked, and the service life is short, so as to achieve mechanical wear and vibration Small size, obvious impurity removal effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

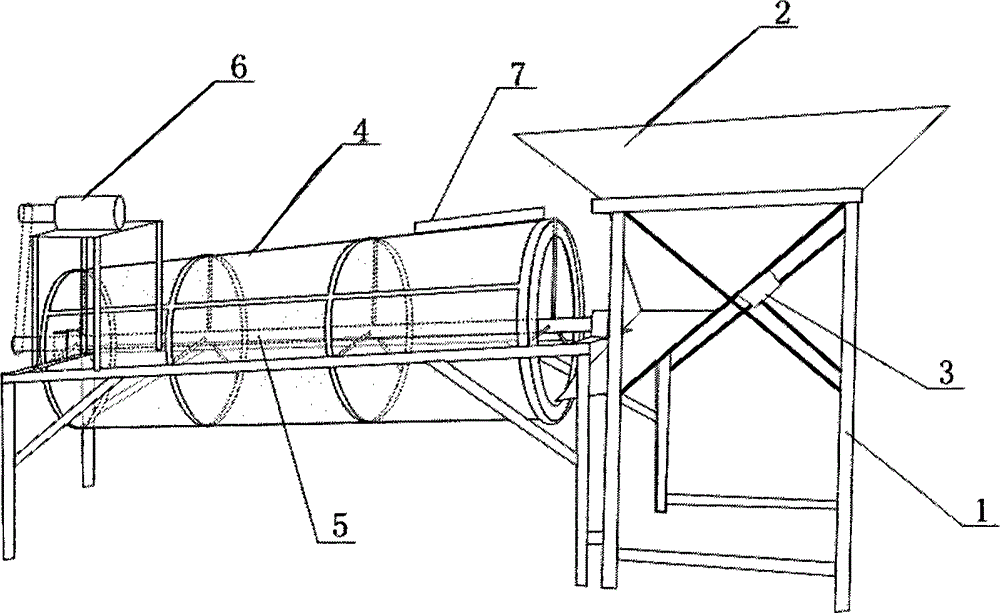

[0021] A trommel screen device, composed of a bracket (1), a feed hopper (2), a door (3), a cylindrical screen (4), a rotating shaft (5), a motor (6), and a scraper (7) composition. The feed hopper (2) is fixed on the bracket (1), the door (3) is located below the feed hopper (2), the cylindrical screen (4) is fixed on the rotating shaft (5), and the scraper (7) is fixed On the cylindrical screen cloth (4), the rotating shaft (5) and the motor (6) are fixed on the support (1), and the motor (6) is connected with the rotating shaft (5).

[0022] When working: turn on the motor (6), the motor (6) drives the rotating shaft (5) to rotate, and then makes the cylindrical screen (4) roll, pours the powdery material into the feed hopper (2), and passes through the door (3) ) to control its feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com