General switch detector

A detector and switch technology, applied in the field of general switch detectors, can solve the problems of increasing tooling design and processing time, not being able to observe the switch module channel in real time, complicated test process, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

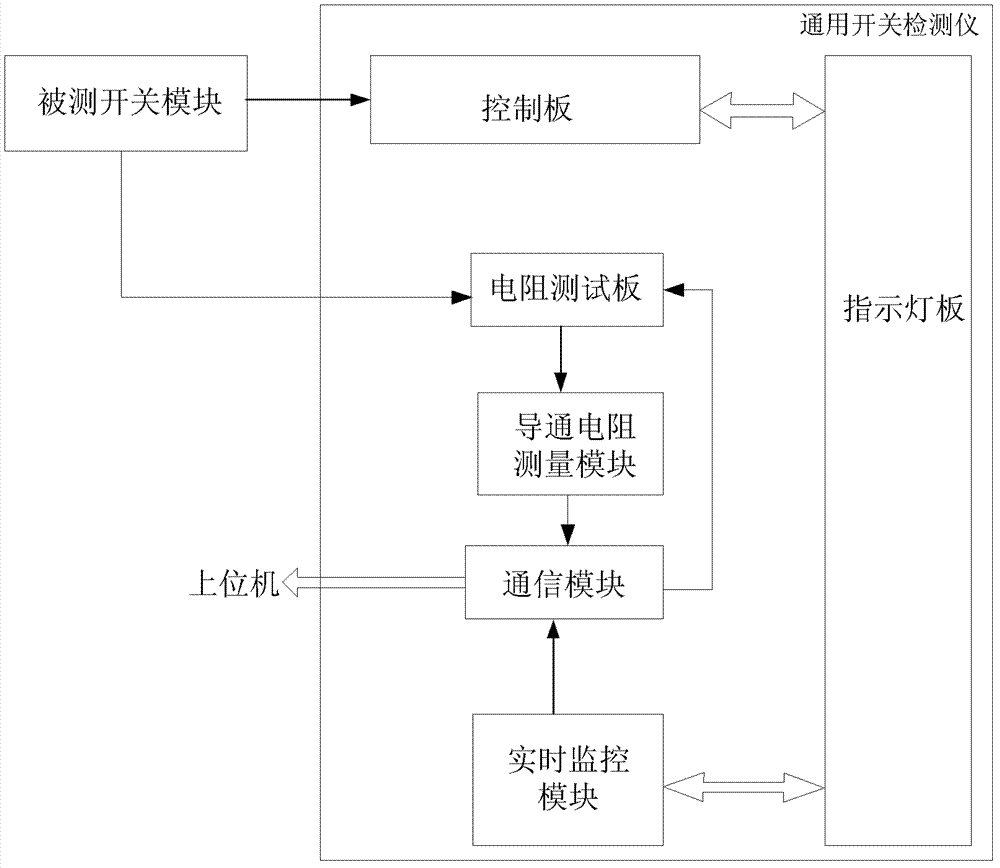

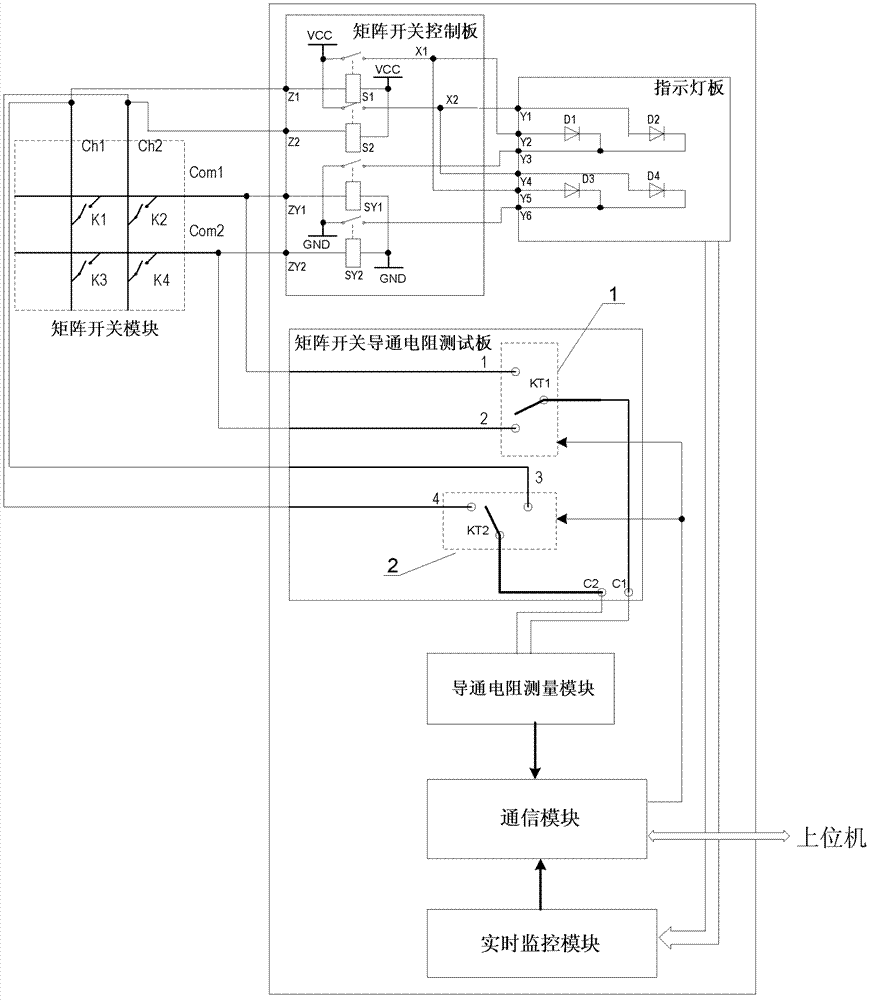

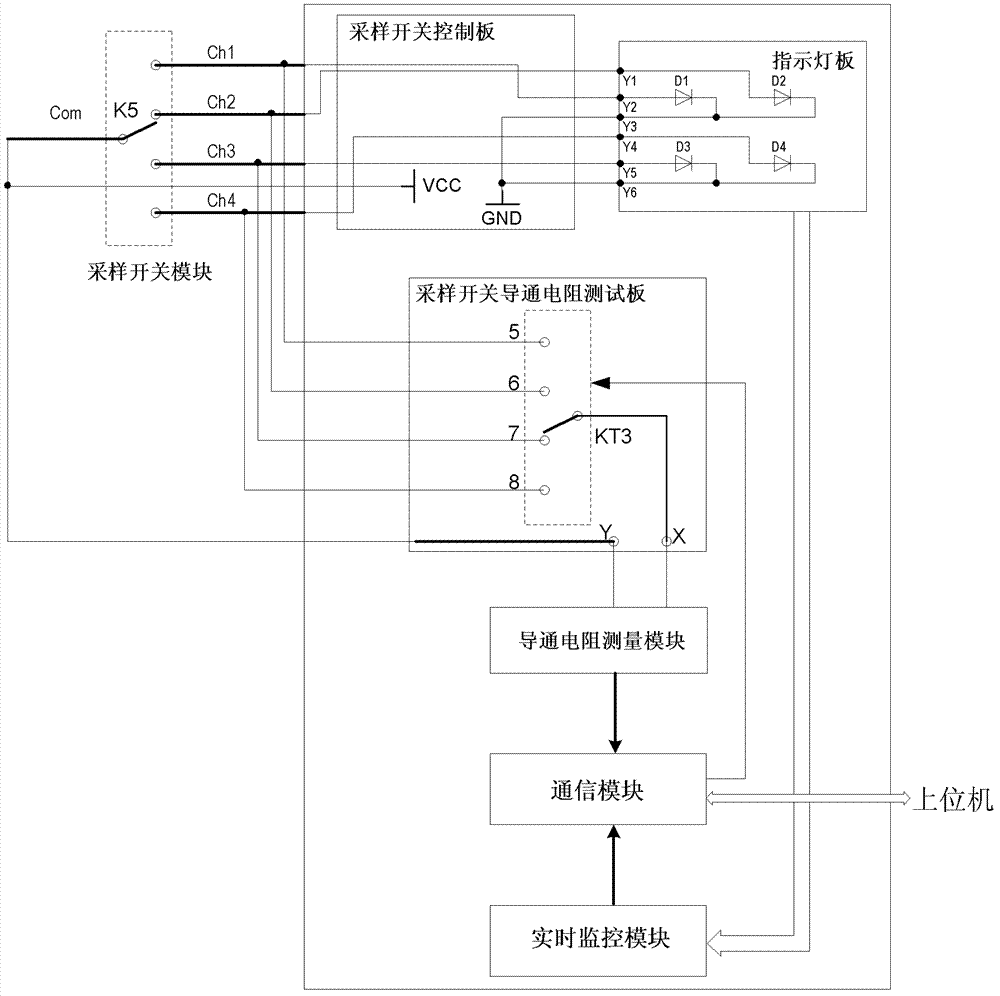

[0030] The invention provides a universal switch detector, including a control board, an indicator board, a resistance test board, a conduction resistance measurement module, a communication module, and a real-time monitoring module, wherein:

[0031] The connection relationship of each component of the detector is as follows:

[0032] The external switch module to be tested is connected to the indicator board through the control board and the on-resistance measurement module through the resistance test board. The communication module is connected to the on-resistance measurement module, the real-time monitoring module and the resistance test board respectively. The indicator board is connected, and the external host computer exchanges information with the communication module.

[0033] Both the control board and the resistance test board are replaceable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com