Permanent magnet type vacuum circuit breaker

A vacuum circuit breaker, permanent magnet technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve problems such as immature technology, difficult technology, complex structure, etc., to improve mechanism reliability, reduce costs, The effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

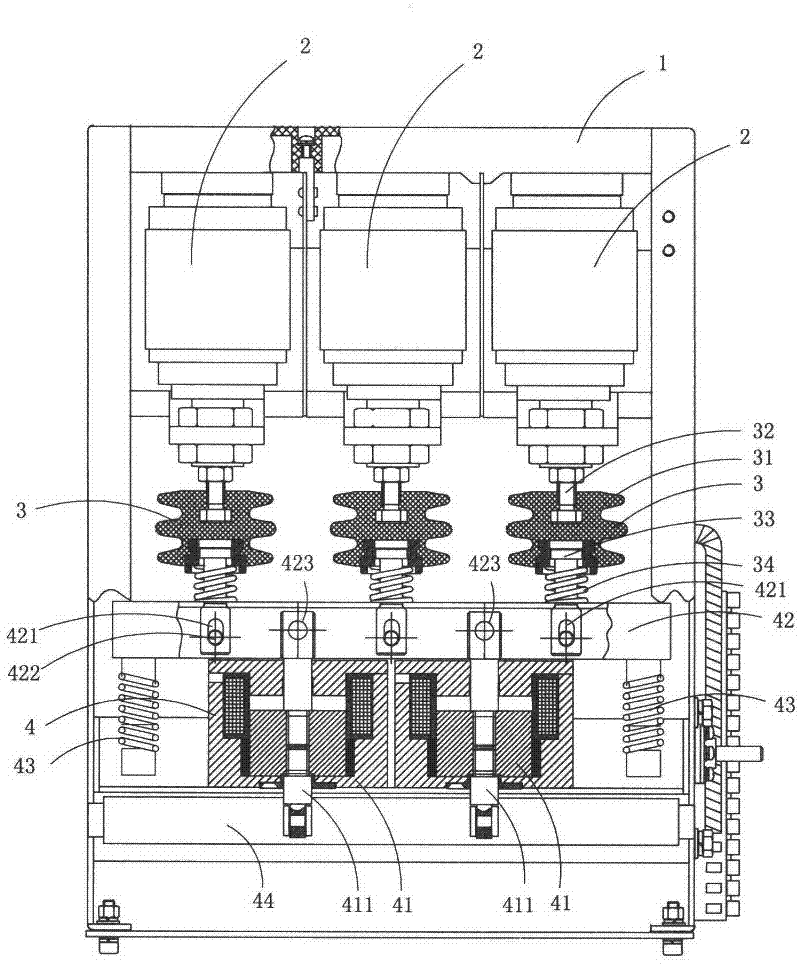

[0018] figure 1 It is a structural schematic diagram of the present invention, showing a specific embodiment of the present invention.

[0019] This embodiment is a permanent magnet vacuum circuit breaker, see figure 1 As shown, it includes a frame 1, three vacuum switch tubes 2 arranged on the frame 1, an insulating pull rod assembly 3 connected to the moving contact in each vacuum switch tube 2, and an insulating pull rod assembly 3 for driving the insulating pull rod assemblies 3 to move synchronously. The permanent magnet drive device 4.

[0020] The permanent magnet drive mechanism 41 includes two permanent magnet drive mechanisms 41 each provided with a drive shaft 411, a linkage rod 42 fixedly connected to the two drive shafts 411, two auxiliary opening springs 43, and a synchronous shaft 44; the linkage rod 42 is also connected to the three insulating pull rod assemblies 3; the two permanent magnet drive mechanisms 41 drive the linkage rod 42 to reciprocate through t...

Embodiment 2

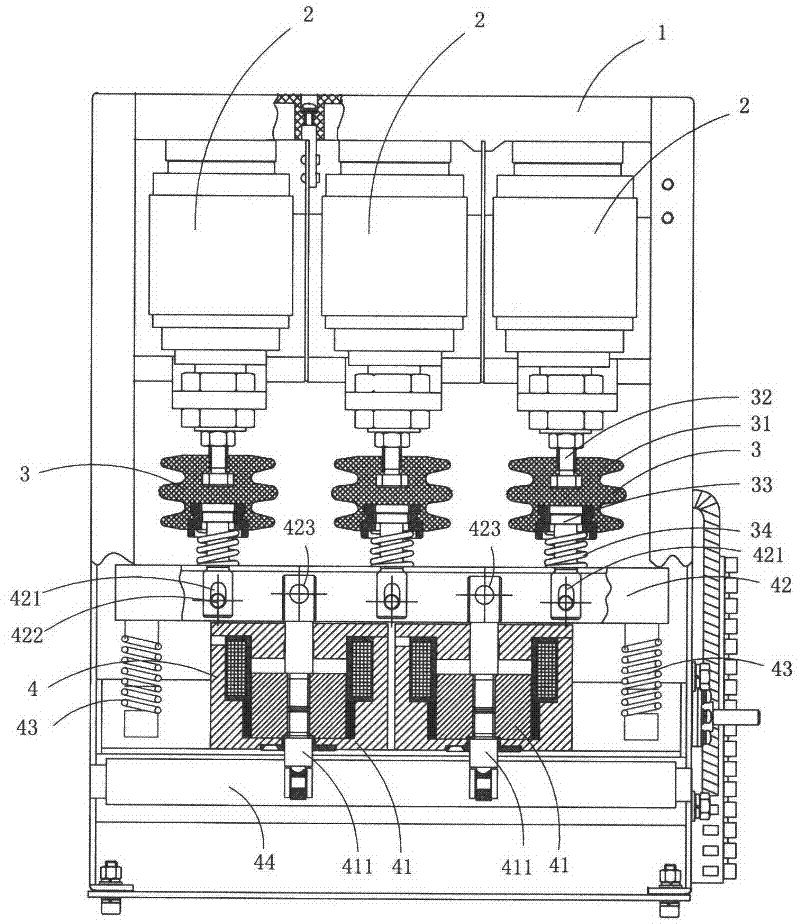

[0030] This embodiment is basically the same as Embodiment 1, except that the three switch tubes are located directly above the linkage rod 42, and the two drive shafts 411 are arranged directly below the linkage rod 42; There is a waist-shaped hole 421 for connecting with the pull-down rod 33 and a circular shaft hole 423 for connecting with the drive shaft 411 that pass through the linkage rod 42 along the vertical direction, and the bottom ends of each pull-down rod 33 are vertically aligned. The line direction extends into a corresponding waist-shaped hole 421, and is connected with the linkage rod 42 through a circular shaft pin 422; the upper end of each drive shaft 411 extends into a corresponding circular shaft hole 423 along the vertical line direction, And link to each other with the linkage rod 42 through a circular shaft pin 422 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com