High-speed taking device for photovoltaic stacked silicon slices

A silicon wafer, high-speed technology, applied in the field of photovoltaic stacked silicon wafer high-speed pick-up device, can solve the problems of cumbersome mechanism and inconvenient use, and achieve the effect of simple structure, simple operation and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

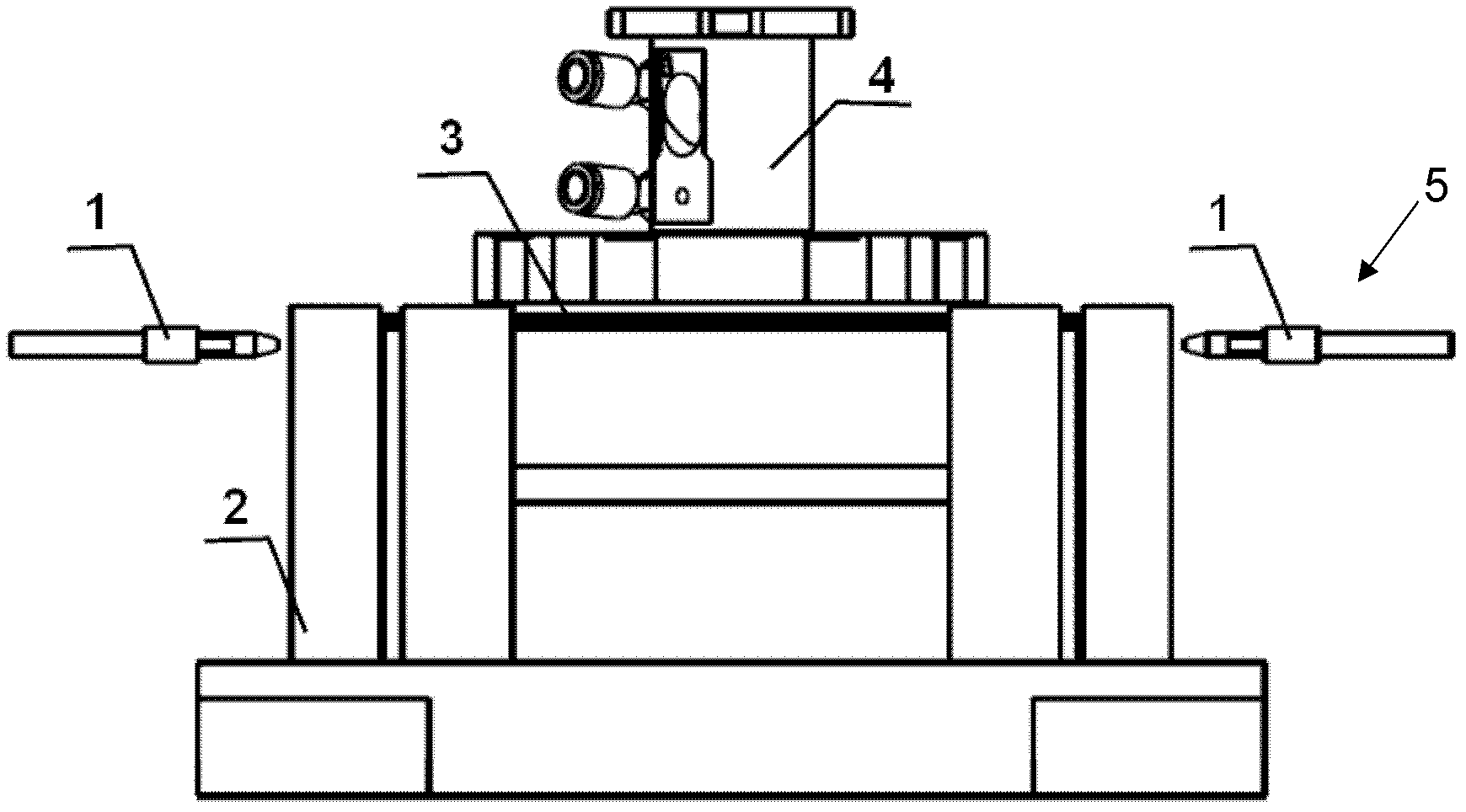

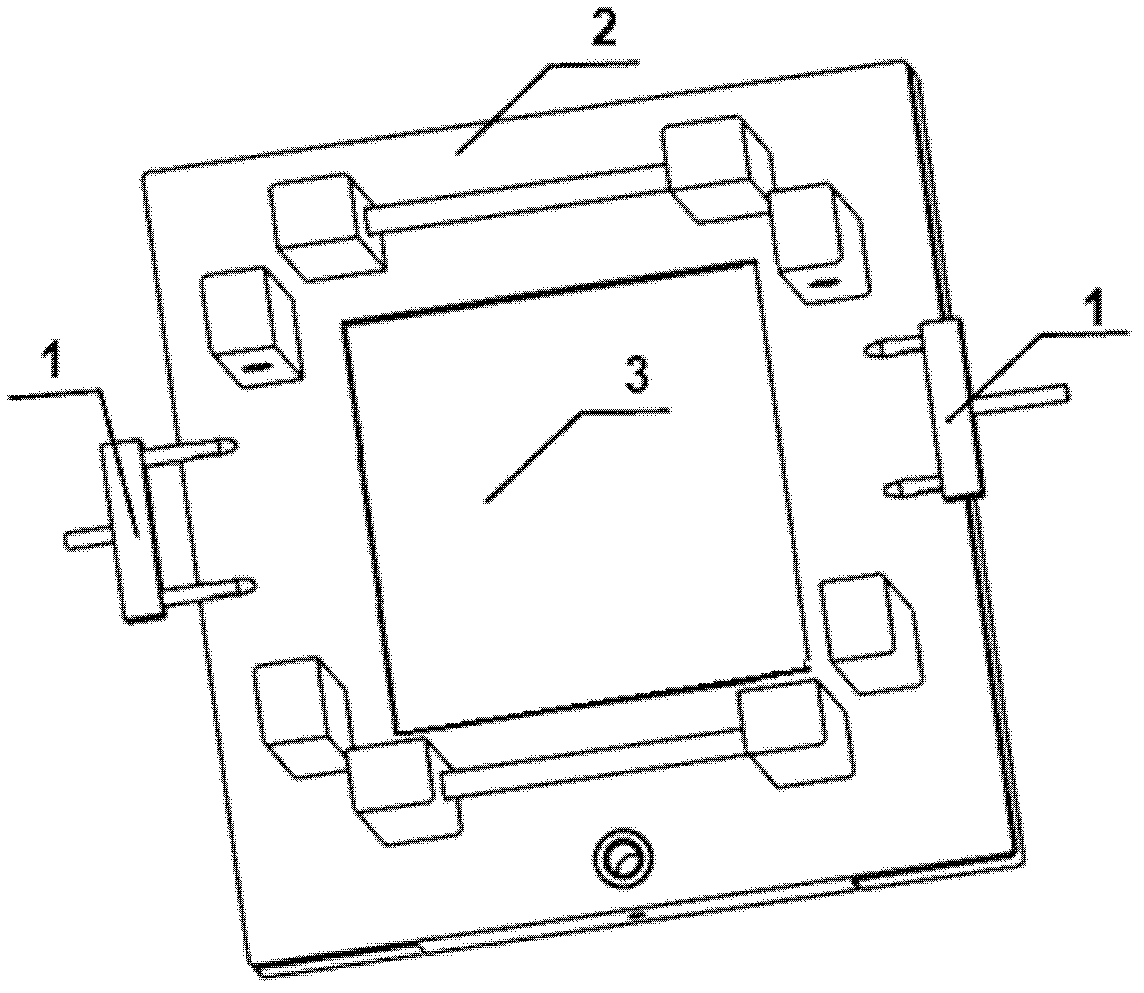

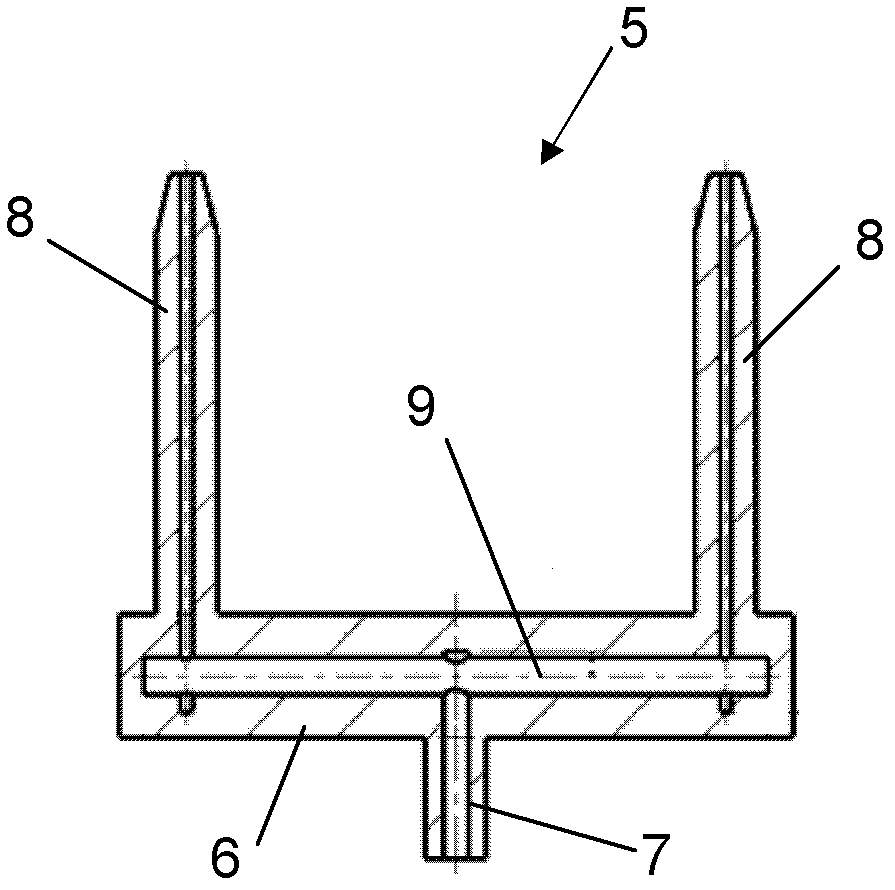

[0019] Such as figure 1 , figure 2 As shown, the photovoltaic stacked silicon wafer high-speed pick-up device of the present invention includes a silicon wafer box 2 with silicon wafers 3 stacked inside, a combined air knife 1 arranged on the side of the silicon wafer box 2, and a combined air knife set above the silicon wafer box 2 The high-speed suction cup 4, the combined air knife 1 includes the opposite-blowing multi-hole air knife 5 symmetrically arranged on both sides of the silicon wafer box 2, and each of the counter-blowing multi-hole air knife 5 has a structure such as image 3 Shown, comprise cutter body 6, be located at the air inlet pipe 7 of cutter body 6 one ends, be located at a plurality of parallel blowing nozzles 8 of cutter body 6 other ends, have in cutter body 6 and have air inlet pipe 7, blowing The mouth 8 is connected with the air duct 9. The number of mouthpieces can be two, three or more, image 3 Shown are two. During use, when the silicon waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com