Corn stubble digging and stalk-stubble smashing device

A stalk crushing and crushing device technology, which is applied in the field of agricultural machinery, can solve the problems of increased slip rate of the transmission system, decreased cutter speed, and pressure rod, etc., and achieves the integrated operation of field return and stubble removal, reduces power consumption, and ensures The effect of job quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

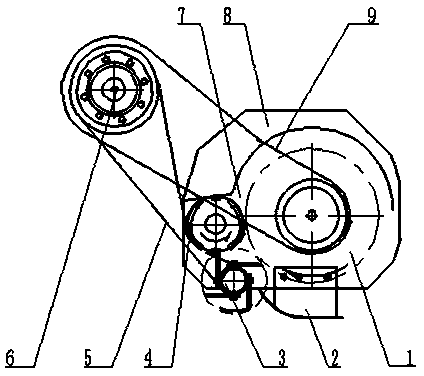

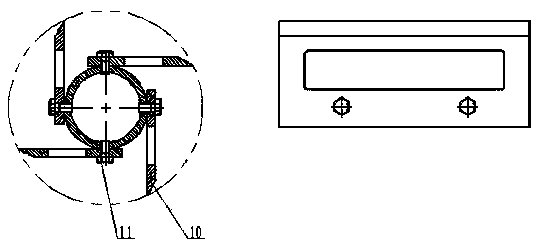

[0015] This embodiment is used to illustrate the present invention, but not to limit the present invention. Such as Figure 1~2 In the shown embodiment: it can be used with self-propelled and suspended corn combine harvesters, or it can be used with tractors alone. In the digging stubble cutter (3), the cutters (10) are installed in groups on the pipe shaft by bolts. (11), the pipe shaft (11) is installed horizontally on the side plate (7) of the frame, and the field returning knife seat in the stalk crushing device (1) is arranged in a spiral line and welded on the field returning knife shaft for installation and returning to the field Knife, casing (8) is installed on the outside of stalk pulverizing device (1), and each cutter shaft is all installed on the side plate (7). Cutters (10) in the excavation type stubble cutter (3) are fastened on the pipe shaft (11) by bolts, and the cutters (10) are formed into groups, and each group of cutters (10) is arranged symmetrically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com